-

Posts

526 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by NickOHH

-

-

15 minutes ago, rthibeau said:

did nickohh get a hammer ???

I didn't get a hammer :(

-

Awesome tree! Love the mushroom too nice touch.

-

29 minutes ago, Steve Sells said:

hammers, tongs, pancake flipper. think man... anything you can make from mono steel could have been pattern welded steel

I've just had my breakfast, I may start to think now.

-

Hey welcome to the site, not to far from you near, near brookhaven. Pm me if your interested in meetin up one day.

-

I have been playing around with trying to get the hang of damascus and was wondering what to make other than a knife. I tried a bottle opener that works but it split on the tab that catches the cap, gonna try another. What are some things you have made or seen made out of pattern welded steel?

-

Awesome frog das, nice work, you can just mail that to... Seriously though good job

-

Does it clink

-

A pic would be helpful, is it hard like a layer of scale or it could be scale marks from it on the anvil and the texture is getting hammered into it. Could be ash and gunk from the fire? I'm sure there are lots of ? I didn't ask but a pic would be helpful

-

Add coal before you take it apart so you have some fresh coke to start the next fire with

-

Check the knife making class write ups out... Covers everything

-

5 minutes ago, DSW said:

The smithing coal he bought at Peoples down the street from Andrews shop is from about 3/4" down to fines, though there are a few occasional bigger pieces.

Ah ok, weaverland got a load of nut insted of pea this time, still burns good, don't like the size though

-

8 minutes ago, Forging Carver said:

Size of the knifeand? The knife around 6-7inches

The coal but yea that 2

-

3 minutes ago, Forging Carver said:

Nah I'm the master at heating only one end. Only when I just got my new coal I could heat one end!

Oh yea, what size did u end up with.

-

Lots of hurry up and wait

-

2 minutes ago, Curtis87 said:

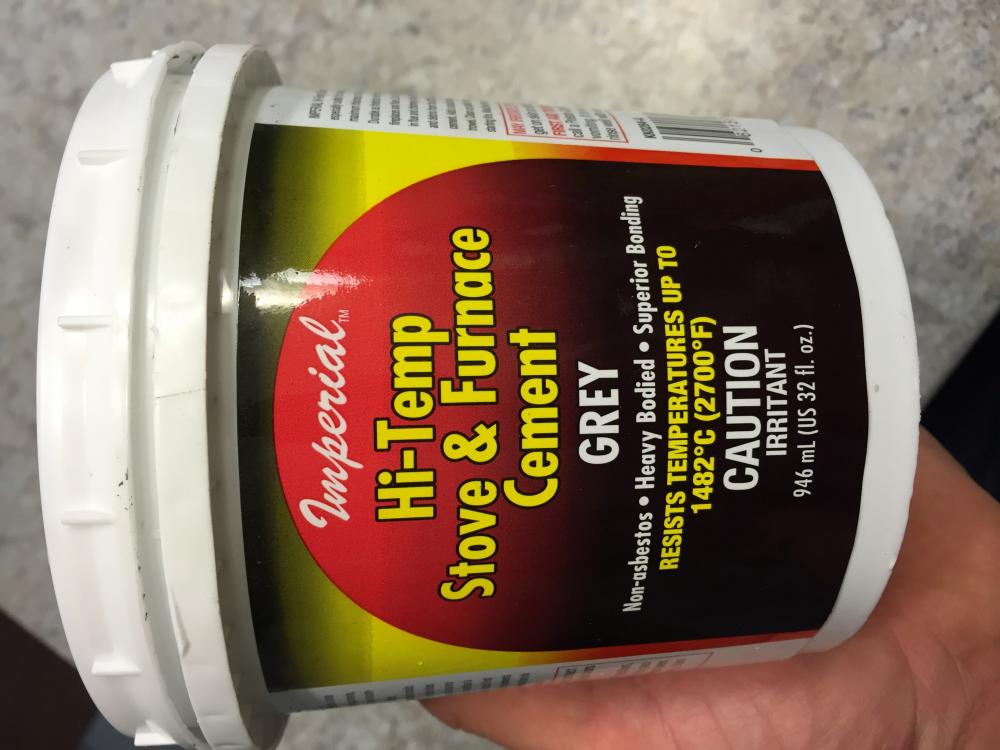

You can put it in the oven not to hot though, treat it likes ribs in a smoker almost , long heat at low temp because the outside will setup first but can lead to cracks once it's mostly dry throw it in the forge and start a fire for awhile then add coal/air

-

7 hours ago, Crazy Ivan said:

I'm also into both the music and the medium as well. Pittsburgh PA here. Welcome to the forum and congrats on your new addiction.

Nice, what kind of music??

-

4 hours ago, Frozenthunderbolt said:

I'd say quench just the tip, and temper the tip end 30mm (inch and a 1/2 ish) to a blue temper. For a thrower you want to be able to get a fairly strong tip sharpened in for penetration. Leaving the rest of the body annealed/air cooled soft is good advice.

Seems like your best bet, remove forging stress and decrease grain size then ht tip so it stays sharp could clay the rest of it if it's hard to heat just the end

-

54 minutes ago, Q Fausey said:

Ok when I was done shaping my knife I quenched it in canola oil but there was a twist in the blade so I heated it back up fixed the twist then quenched it agin in the same oil I then ground the blade thinner than a dime thickness as already discussed and tempered it in the oven at 435 for an hour till it was straw yellow after that I let it cool polished of the temper colors and tempered it the same way another time I then sharpened the blade all the way and discovered that the edge got little chips in it even when carving on soft wood then I came here and posted this to try and figure out the problem I do aprieciate all the help so far but we have not gotten anywhere

How hot did u take it to quench it? And was the oil warmed or was it cold

-

Welcome to the site, Just outside of philly in Delco . You will learn a lot here .

-

37 minutes ago, Forging Carver said:

So do you mean let it air cool or cool it in sand. Maybe do it a few times? Thanks

Normalize, air cool, a few times from progressively less heat a bit over non magnetic right before it changes and a bit under

-

I don't claim to be an expert by any means but from my understanding, I would say one drift, with a long gradual taper, think triangle profile with rounded corners. The eye should be a taper that matches the wedge that the head requires, which comes down to intended use ie a axe for hardwoods, softwoods or splitting or if you want a general purpose. Eye size will depend on overall weight also heftier head would want a slightly wider eye to handle the increased force. Try all the axes you can and see which you like and which you don't , what patterns you like then match the eye according to shape desired.

-

Thanks Das, gotta keep me posted if you try one.

rockstar, thanks for the tip, it worked better than I thought but I will try cutting the edges a bit with a chisel a bit.

-

Yup, I agree look into the 55 forge blueprints. I use one, it works well for me. Cheap, works good and was simple and quick to throw together.

-

Bday present for my nephew

in Knife Making

Posted

Awesome knife, nice job.