setlab

Members-

Posts

199 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by setlab

-

What's a good email for Clay Spencer?

setlab replied to setlab's topic in Power Hammers, Treadle Hammers, Olivers

Ya but that like requires me to talk to people and stuff. -

what should I preheat 1.5" plate to?

setlab replied to setlab's topic in Welding/Fab General Discussion

It's a millermatic 200, right now there's .035 wire in it and I'll probably just use that. I've been told the 1/4" wall tube is on the upper limit of my machine. I'm playing around with the idea of making a shelf below my anvil to brace it too. So far I've already cut my legs at 15 degree angles so I'm pretty committed to this design. Basically I'm copying this stand: http://www.iforgeiron.com/topic/28153-another-anvil-stand-build/ It'll look neat and it's something to do so why not. Plus I have bigger "upsetting blocks "so no big loss there. -

what should I preheat 1.5" plate to?

setlab replied to setlab's topic in Welding/Fab General Discussion

It's a decent sized mig machine for my shop, it will do the job. I assume both plate and legs are mild steel, and I'm not real sure how many passes it will take. Whatever looks right I suppose, I'm far from a professional but I can make a pretty looking weld most of the time. -

what should I preheat 1.5" plate to?

setlab replied to setlab's topic in Welding/Fab General Discussion

Ya, 1.5" is a little thick but I just happened to have a piece that fit perfectly under my anvil. Thanks for the help. -

I'm welding 3 legs to a 1.5" plate to make an anvil stand. What temperature should I preheat the plate before I weld on the legs?

-

Ok, I wasn'the sure what way I wanted to stack the wood yet. Makes sense with the wood swelling up, thanks! For the most part the plates are pretty flat, there is a little wobble in them stacked but thats from some torch Slag on a small portion of the edge. I still need to play around with them and clean up the edges for sure. Let's just say theoretically here for educational purposes, the plates were totally flat without any wobble and weighed about 160lbs would that theoretical mass be a significant benefit to forging on an anvil of about the equivalent weight?

-

This isn't going to be a serious endeavor, just something to pass the time until I actually put time aside to build a real press. I'll be more than happy if it will squeeze a hot piece of metal faster then I can forge it by hand.

-

I know what you mean, harbor freight usually makes me cringe but it looks like people have had luck with them. I was mainly concerned about the play in the top ram that comes down, there's maybe an 1/8" of play back and forth. Could that cause something to spit out at me?

-

I have a 30 ton H frame press that's been collecting dirt for awhile and was thinking about getting one of those harbor freight 20 ton air bottle jacks for it. So far I've read a handful of topics for those little air hydraulic presses but everyone seems set on building their own press frame for them. Is it a wise idea to use this 30 ton frame as a 20 ton forging press host? For less then $100 and hardly any time on my hands it sounds like a great idea after seeing what these small presses do on youtube.

-

I have it laying on my coffee table as I type this, I still need to re-read it a couple more times though. If monstermetal's on to something spectacular with the speed of his press I would much rather use the components he uses then the seemingly "cookie cutter" press build that Batson's book teaches about.

-

A kit option would be great, it would take a ton of legwork and guess work out of building a press. Motor/pump/cylinder/controls and that's it.

-

Meh I'm a bit of a hermit

-

Pensacola

-

I was on the fence about ruining it's collector value if it had any by doing a repair. I'll take your advice and keep it as is, maybe I'll keep it around to trade at the next blacksmith conference I can make it to. I kind of with I had a space in the shop to put my "cool stuff to look at" but it's jammed packed as it is, I know this old anvil would just get pushed in some random corner if I didn't repair it.

-

I found a neat little anvil in a barn that I just bought, it has a little bit of rebound when I drop a hammer on it. I kind of want to keep it around, it looks unique and it's nice to have a small anvil that's easy to move around the shop. But in order to earn it's keep I want to weld up the faces and grind them flat and new again. I'm guessing that it's an older forged anvil from the really short heal and the holes in the anvils body so I assume it's weldable? What do you guys think? Should I fix it up new or let it be and sell it to someone else to try and use as is? I can't find any markings anywhere on the anvil and it feels to be about 75lbs. Any Ideas of what brand it is?

-

Thanks, I'll have to keep Panama city in mind if I ever get out that way.

-

Anyone around the Pensacola area? Is there any scrap yards that will sell to us in the area? There looks to be one in Atmore but it's quite a drive away. I just moved into a larger shop where I can run my welders and have a real blacksmith setup again, finding a source for small random pieces of metal would be great.

-

I started with a peter write and currently have a fisher, they sure are quiet and I really like mine. Who's to say where this double horn came from, It looks like something that was imported a really long time ago but there doesn't appear to have any markings on it.

-

Well, I already have an anvil that suits my needs just fine. This anvil defiantly has the cool factor though but I'm more interested in respecting my new neighbors as I haven't lived here for too long.

-

How much louder is the ring of a double horned euro style anvil compared to your typical single horn anvil? It would seem to me with two horns, especially longer thinner ones of the euro style there would be a bit more ring. I found a guy selling about a 300lb double horn anvil, from the looks of it the anvil has a bit of age to it and the price seems right even with the long drive to get it. I've always liked the look of those double horned anvils with the upsetting blocks on the side and I've never had a chance to use an anvil over 150lb before so this one looks pretty good to me, the only thing is I really don't want to bother my neighbors even more than I already do.

-

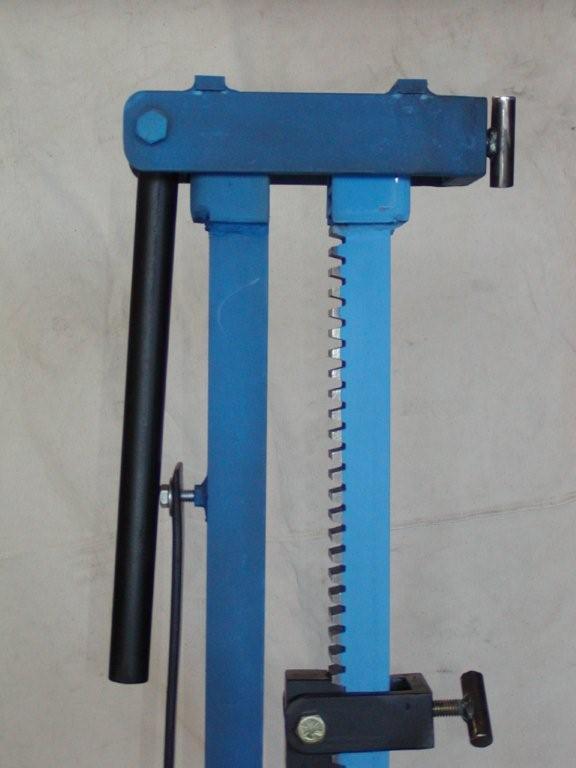

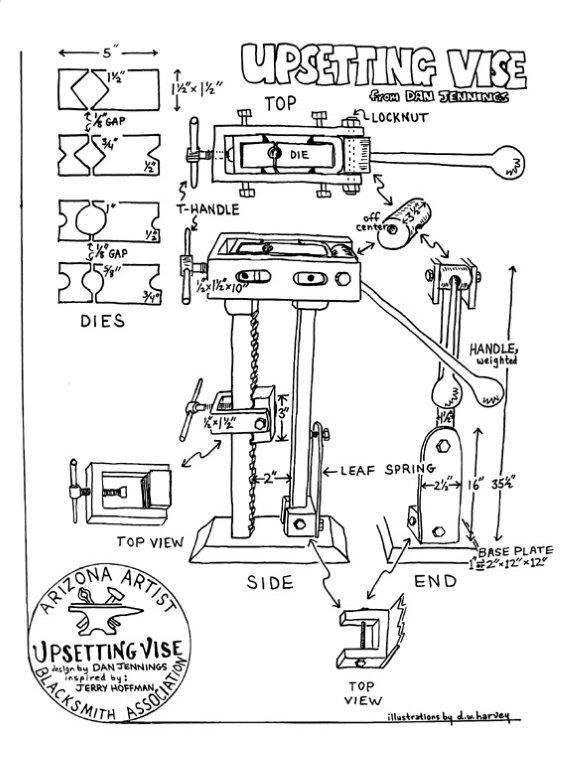

That adjustable block is for the end of the bar or whatever your upsetting to set on. So it has nowhere to move when hammering it. I suppose with a lot of time you could make a pretty nice substitute for that gear rack, I like the idea of stumbling across one at a scarpyard a little better though lol. Enco sells 1.5" square gear rack for about $150 for 4' in comparison.

-

Has anyone ever made a vice like this? Looks like it would be really useful for upsetting. If I had a scrap piece of that gear rack I think I'd be building one now, but that stuff looks kind of expensive for an experiment. http://azblacksmiths.org/plans/upsetting_vise.htm

-

Sounds like an awful lot of time and work for such a small "anvil". Why not just weld a piece of square tubing to the side of your rr track to hold hardees?