-

Posts

1,746 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Anachronist58

-

-

I do not mean to short circuit your line, nor to induce reluctance to further zingers, but there is an overload of puns currently flowing...

mcostello, I prefer to call it a plug too far...

Robert Taylor

-

Outstanding images, by the way...

Robert Taylor

-

What cute is not cute? Electrocute!

-

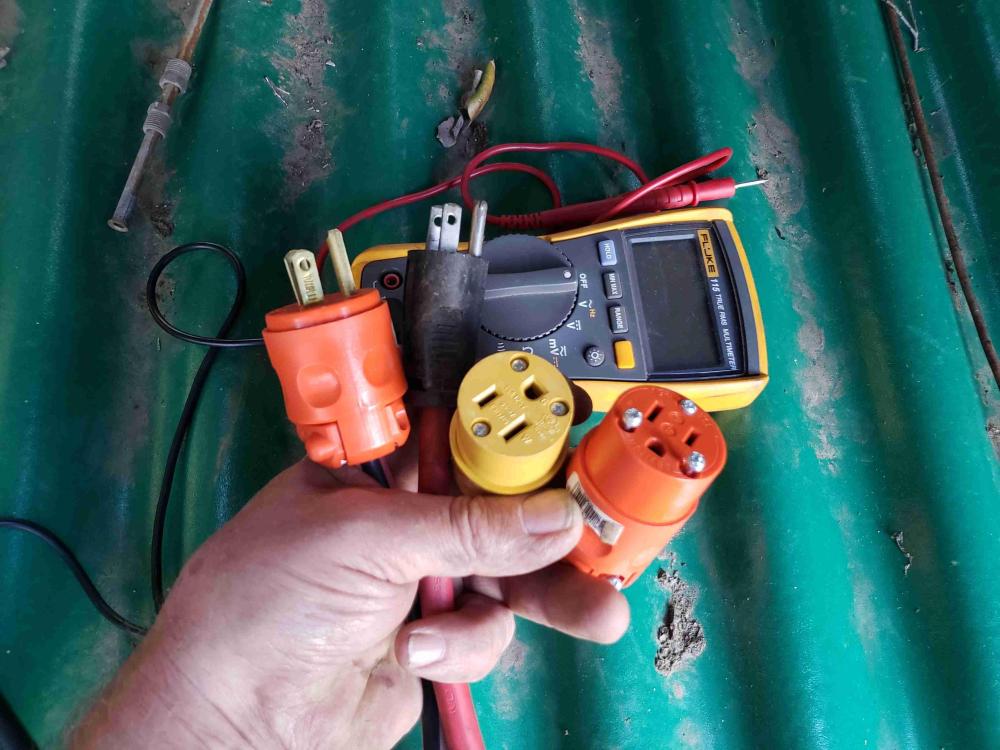

I needed to weld an extension on one of my fence poles. Tried to use a l00' 14-3 cord on my little HF dc inverter. Just a bit too much drop on the line to maintain an arc. Did not want to reinjure my back by wrassling the genset.

So, refurbed the 75' 12-3, and dragged the end up to do a ring test. OOPS. Needless to say, I was a bit shocked...

These two females were right next to the male. Swapped out, and got the job done. Will give you a laugh when you see the weld...

I have a thunder stick for intruders - no need to bring the lightning...

-

Same cable. One end has been out in the weather for eleven years. Yep, two male plugs on the same cable. With my arthritis, I was so happy that it only took six minutes to mount the new plug, only to.... oops! Happy New Year!

Robert Taylor

-

Ha! Some distinguished guest directed me to this thread. I tried to use my three ton Famco like a forging press, and shattered the hub on the cast iron handwheel. That convinced me that it was time for a flypress.

Robert Taylor

-

2 hours ago, Nodebt said:

How does that work, Robert

Scott, you have won the prize!

1 hour ago, Daswulf said:unless I need it now.

Oh I needed it, alright! Notice anything odd about it? TW?

-

Especially if you use one male and one female.

-

It was real fast. And in most every aspect, perfect.

-

-

Google Earth fetches with 'parting of the waters' . Very nice...

Same for googoo maps...

-

23 hours ago, Daswulf said:

and are on the mend.

Doing as well as a lot of my friends these days...

-

On 1/9/2022 at 10:03 AM, ThomasPowers said:

I'd cut one up (...) most likely what you'd get is mainly "bragging rights".

And Thomas, I have a surface grinder, and that would be da bomb! Now* to find some lifters! (And not be laid up

). Nice to contemplate these things, in the least!

). Nice to contemplate these things, in the least!

Robert Taylor

*figuratively

-

Gorgeous, organic andiron! Got to go now!

Robert Taylor

-

Wishing you great success, Mr. Stickman.

Robert Taylor

-

Since we are talking lifters here, and not valves, there should not be any concern about sodium. You are responsible for ensuring your own safe conduct. Were they my lifters, I would be all over taking one apart, since I have determined for myself that it is safe to do so. If they are 'high end' lifters, there will be tiny needle rollers between the roller and its shaft. Could make for an interesting pattern.

Robert Taylor

-

Ha! I just inherited a Taiwan built Rong Fu horizontal Bandsaw. Probably a bit older than your little mill... NICE readout...

Love it.

Robert Taylor

-

On 11/9/2021 at 4:36 AM, Calkidd said:

I understand. I saw the sub-forum here

Yes, Yes! we really want to know! I wish I had seen this post when it first went up, I would have been all over searching it out. It has an encouraging Mfg. date... Thanks for dredging this up, Scott.

Robert Taylor

-

She and her loved ones continue in our prayers...

Robert and Sheila Taylor

-

On 12/31/2021 at 2:09 PM, ThomasPowers said:

ever tried making a milling machine bit?

Yes. I have had to prototype a few milling cutters for titanium and superalloys on our vintage manual grinding machines. Had to cobble together an on-the-machine microscope to nail a christmas tree cutter for a turbofan disc. I thought they were crazy, was thinking about finding another job... and then there was the time...

1 hour ago, arftist said:No, that isn't how it works.

You have it right, Mr. Arftist.

Robert Taylor

-

In honor of this being page # 777 on this thread, let me tell you that I have been overwhelmed by the stuff that can be discovered here. Best I can do, is skip back a couple of pages. Here is what I did the shop today. It is a chili with no beans pipe clamp:

Safe and happy holidays, everyone!

Robert Taylor

-

Love your work.

Robert Taylor

-

-

I love this guy. And yes, he has a humongous machine / fabrication shop. And yes that vise is over the top, but he uses it to good effect on some subsequent videos...

Robert Taylor

So Proud

in Everything Else

Posted

Beats getting zapped!