-

Posts

31 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by BANAN

-

Change only the nozzle greater.

-

The first five burners in the first photograph, can run 5 miles from the socket

-

The advantage of naturally aspirated burner is that it does not need power. Burners operating with fans have the advantages of a lot more. I will mention here less gas consumption, adjustable flame atmosphere, the opportunity to work with a heating recuperative air supplied to the burner, absolutely safe operation without rolling back the flame to the burner. Such an image as the photograph is very common in my forge, sometimes it can not keep up with the production of burners. Demand for cooperating with ventilator burners is very high. None of the blacksmiths who once worked on the burners naturally aspirated, does not want to return to them.

-

-

Power hammer M4129

BANAN replied to santisandreas's topic in Power Hammers, Treadle Hammers, Olivers

It is the Soviet hammer. Information about it can find no problem at forum.ostmetal.info -

Forum is in Polish. Aspirated burners are ineffective. I lost three years to experiment with burners to develop its own model of working with fans and giving full control of the flame atmosphere. They convinced them Polish blacksmiths, even those who could not imagine working at another hearth than Coke. My burners work in more than 200 forges, and it speaks for itself.

-

Vito, you write that you're from Slovenia, it may be easier for you to move Slavic blacksmith forum. We've got a lot of experience in the construction of gas furnaces, and is different from local. http://forumkowalskie.pl/viewtopic.php?t=76 Of course, we started from the burners naturally aspirated, but everyone still wants to have an effective and economical tool.

-

Your mistake is that we do not at this point arson burner. The burner ignites at the mouth of the flare, rather than at the outlet of the gas nozzle.

-

Yes you are right, the pressure gauge should be read in conjunction with the gas nozzle diameter. In my large burners I use jets of 1.2 millimeters and 1.0 millimeters smaller. The gas passing through the larger nozzle with a small pressure not cools as passing by a smaller die with high pressure. I did my first burner like so many on this forum atmospheric. 11 kg gas cylinder was sufficient for 8-9 hours. Burners currently used with recuperation and air blowing the same gas bottle is enough for 13 hours of operation with a large burner and 15 hours of operation with a small burner.

-

Under the floor of the furnace is integrated recuperator heats the air. Gas falling into the hot wind increases its volume, therefore, it need less. From here indication of the regulator close to zero. Heated is a nitrogen, which is 70% air. This results in an increase in the flame temperature. Forced airflow makes it possible to regulate the flame of reduction through neutral to oxidizing agent.

-

Urgently I am watching actions of new builders of gas hearths and with distress I state that they didn't break the certain stereotypes concerning the structure of burners. When I started my experiments with gas, I aspired for creating the strong, compact and economic burner. Over 200 burners made by me are heating iron up not only in Poland, but also also in England, Scotland, Germany, Portugal and Belarus. Many blacksmiths from Russia made also burners on the basis of observations of my burners. I will give a few links to films still for documentation where in stoves my burners are applied.https://www.youtube.com/watch?v=VvHDp1tscac https://www.youtube.com/watch?v=vDR_w0RCtTk https://www.youtube.com/watch?v=YWASmKTW_wk https://www.youtube.com/watch?v=QVrK00sVkC0

-

Many have seen the gas forge. I would like to show you forge., Which was established on Polish Forum Blacksmith as model

-

I like this solution

-

The reason lies in my opinion in a fireproof material used in flare .. With prolonged use heats up like a wall oven and ignite the mixture occurs already in it, and not in the chamber of the stove.

-

I'll try to explain the advantages of natural gas over propane Besides, Because it is always in the tube. Natural gas has a lower temperature to the truth than propane flame, but at a temperature of 1000 degrees C undergoes dehydration phenomenon. Decomposes into acetylene and hydrogen. What is the impact on the increase in temperature probably does not have to explain to anyone. If at the same time take care of recuperation that is heating the air supplied to the burner, the energy gain is undeniable.I hope it is understandable what I wrote. Gonna use the google translator ;)

-

Subtitles Polish, google translator helps. The seventh post on this site. ;) http://forumkowalskie.pl/viewtopic.php?t=76&postdays=0&postorder=asc&start=180

-

I conducted the comparison on the same overall dimensions burner at the same hearth. The differences are noticeable when hot stove when the mixture has to overcome a stream of hot gas pressure. In the burner venturi have little to increase gas pressure. In the burner of the ventilator simply add more air without changing the gas pressure.

-

Pressure natural gas in Poland is 20 millibar. I use a torch of his own design from a photograph two posts above. In this burner, air is fed axially from the compressor through a nozzle, and a diagonal tube is fed gas. tube is not completed any nozzle. One can also use a burner with a fan blowing the film as the post 9 except that instead of the nozzle tubes for propane, without introducing tube nozzle for natural gas. The burners are my design.

-

Natural gas forge :rolleyes:

-

But the question was about the difference in gas consumption. 11 pound cylinder of gas at the burner ejctor enough for me 8-9 hours. The burner air blower for 11-12 hours.

-

Use both hands to subscribe to the opinion of Tom. Venturi burners are not suitable for professional use. Too little power and too capricious. The professional should forge furnace, which should work with a professional torch. As for the economy, the burners blow, either with the fan or the compressor render lower gas consumption and the ability to connect natural gas, which has a huge advantage over propane is cheaper, does not freeze and never missing during operation.

-

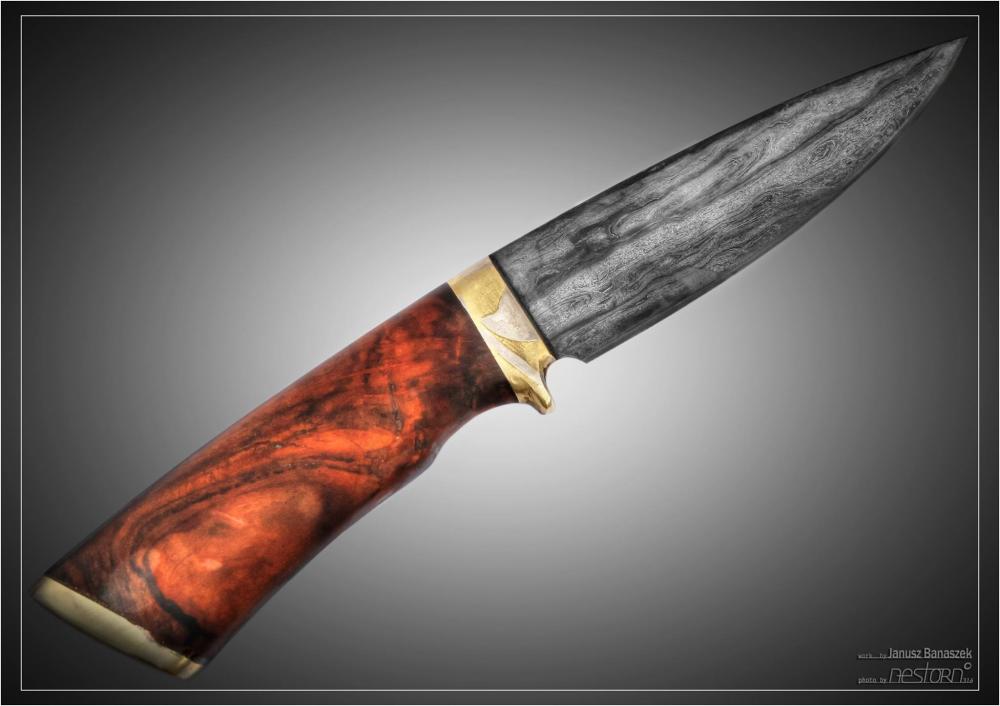

The new incarnations of the burner Banana. Thepower from the compressor side of the gas occurs. In the photograph test firing on natural gas. it promises to be very promising.