eseemann

Members-

Posts

967 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by eseemann

-

About done with my forklift anvil and need advice

eseemann replied to eseemann's topic in Anvils, Swage Blocks, and Mandrels

Thanks all, I did not think it was that great an idea but I thought I should double check. I had good success welding a hardy plate with 1 inch plate (mild steel) gussets on the other part and I did do my pre-heat and sill have all my eyes, ears, fingers and toes. Thanks for the warning. I have to think being at ground zero when #80+ of steel cracks would be a bad thing. -

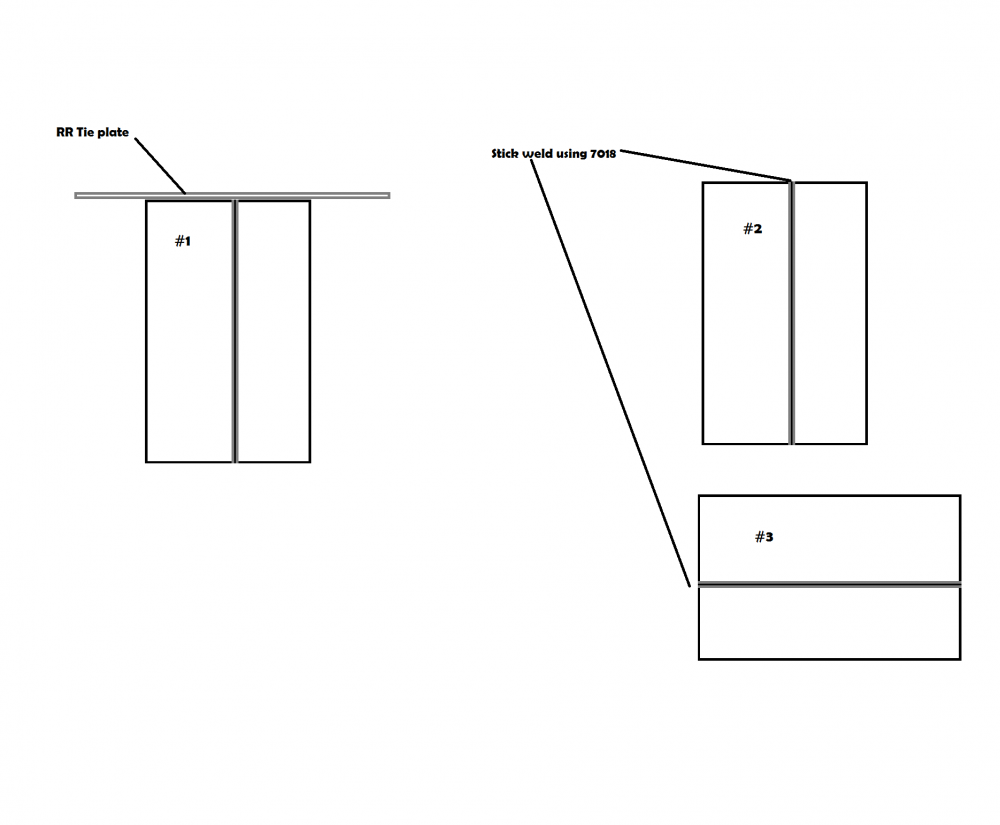

Good Morning all, I about about ready to weld on a hardy plate on to my forklift anvil and I need to ask your advice. I know that a weld resulting from a 7018 rod will not be the same type of work surface as the forklift steel and as it stands I have 2 chunks welded together that weigh at least #65 or #70. I would like to know if you think I should Weld a RR Tie plate on the top of the work surface giving me a single hardness over the entire face but risk the effects of an air gap between the plate and the rest of the steel. not worry about the weld and use full 12/odd inches of mass for down and and the 7 by 4 inch face. Use it like a striker anvil that has a 7 inches by 12 odd inches face is around 4 odd inches tall and risk the air gap where the 2 plates are welded together.

-

Anyone ever build a DIY blasting cabinet?

eseemann replied to eseemann's topic in Machinery General Discussions

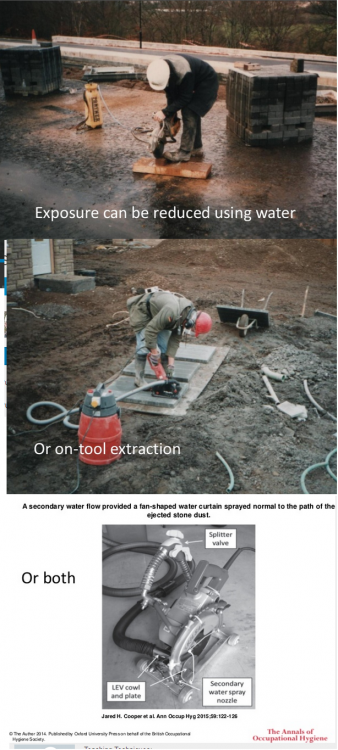

I agree 100% with both 51 Pappy and Genesaika. The problem with small particles of sand is the land in the lung and start to worry (for lack of a better word) the tissue. After a while these particles cause (and this is best case) scar tissue that can cause (among other things) the same COPD you get from being a life time smoker. The not best case (and this is REALLY complicated stuff so any medical professionals out there please be kind) can cause an ongoing immune response that over time can (for lack of a better word) wear out the tumor suppressor genes that keep the genes that rebuild cells from running out of control. This is the reference I was looking for https://www.cancer.org/cancer/cancer-causes/genetics/genes-and-cancer/oncogenes-tumor-suppressor-genes.html This is one of the mechanics of how it might happen. https://www.ncbi.nlm.nih.gov/pmc/articles/PMC1994795/ Cancer and inflammation An association between the development of cancer and inflammation has long-been appreciated [4,5]. The inflammatory response orchestrates host defenses to microbial infection and mediates tissue repair and regeneration, which may occur due to infectious or non-infectious tissue damage. Epidemiological evidence points to a connection between inflammation and a predisposition for the development of cancer, i.e. long-term inflammation leads to the development of dysplasia. https://academic.oup.com/occmed/article/59/2/89/1386756 https://www.cancer.gov/about-cancer/causes-prevention/risk/substances/crystalline-silica onlinelibrary.wiley.com/doi/10.3322/caac.21214/full https://www.cdc.gov/niosh/docs/97-118/default.html One last bit, about filters. I need to ask Genesaika about what you said in reference to paper filters because I plan to get my self a real respirator but I have been using the N95 filter masks. I have had good results so far with the 3M N95 filter masks and I wanted to ask what you thought of these. I know the "dust mask" that are for "nuisance particles" are almost one step better than wrapping a bandanna around your nose and mouth but what do you think of something like these. https://www.3m.com/3M/en_US/company-us/all-3m-products/~/3M-Particulate-Respirator-8210V-N95-80-EA-Case?N=5002385+8720539+3294752926&rt=rud or these https://www.3m.com/3M/en_US/company-us/all-3m-products/~/3M-Particulate-Respirator-07048-N95-20-EA-Case?N=5002385+8720539+3294776360&rt=rud? I like the idea of using water when I can to reduce dust and did something like this when sanding down drywall. -

I am thinking about worm gear drive hose clamps, I guess that is what I think of when I think about hose clamps. The problem with people like my self that don't get in to the hands on work as much as someone that does it for a living is we forget there are going to be more than one kind of most things.

-

My word of advice for the day is don't use the really cheap hose clamps from Harbor Freight or Walmart. I have been using the stainless steel clamps from the Home Despot and I have to say there is no comparison between the cheap clamps and the good clamps.

-

Anyone ever build a DIY blasting cabinet?

eseemann replied to eseemann's topic in Machinery General Discussions

Funny story about that. The People that made Stranger Things did not know that people did not use real 11 year old kids to play 11 year old parts. One reason as follows: This was from an interview talking about the actress that played Number 11 One day she showed up on set and she's just covered head to toe in glitter. And she's like "I don't know where this glitter came from." And it's like I'm not having this problem with any of my adult actors covered in glitter. It's very - I don't know if you've tried to get glitter off someone, but it's very difficult. And yeah, so we fell behind. So she's still a child. -

Anyone ever build a DIY blasting cabinet?

eseemann replied to eseemann's topic in Machinery General Discussions

Thanks Frosty. Genesaika, I have been told that you end up picking sand out of you ears and anything that has the slightest bit of moisture (forget about lip balm) after that. My Sister in Law was deployed 2 times and both times she said the sand gets everywhere. -

Anyone ever build a DIY blasting cabinet?

eseemann replied to eseemann's topic in Machinery General Discussions

From what I have been told "manageable" was the key. The people I worked with that go down to White Sands Missie Range (WSMR) say you need to keep an eye on it and make sure the stuff does not get in to consumer grade items like the Dell laptops everyone+dog is issued. -

Anyone ever build a DIY blasting cabinet?

eseemann replied to eseemann's topic in Machinery General Discussions

Thanks Glenn, good info. -

Anyone ever build a DIY blasting cabinet?

eseemann replied to eseemann's topic in Machinery General Discussions

That sand that people talk about in the Southwestern US and over in the Middle East is the almost talc fine sand that gets in everything. I built a dust catcher for sanding down the walls after taking off the wall paper and that was a Homer Bucket 1/2 full of water and 2 hoses. Worked great since the dust or in this case sand would enter the bucket under water and when any made it all the way to the shop vac it was watery mud. Sand is most dangerous (as I understand it) to the lungs when floating in the air. I figure sand that has been underwater is not 1/2 as dangerous. I am not worried about the steel, wood or plastic holding up since the sand is only going to be able to damage the sides of the box within 1-5 inches depending. 1/2 an inch away you can from the gun the sand will take off baked on enamel and and powder coat but only when you are at close to point blank range. The one he has looks like this. -

Good Morning Folks, I helped a co-worker set up his cabinet and it was kind of a pain because the directions were written by and for people that already knew how it want together. Looking at the thing I see the only few specialized things in the entire setup were the blaster device and the glove/glove rings that you used when reaching in to the box. I think this must be easier to say than do but it looks like you could build one out of plywood and plexiglass. You would need to use (I would think) an N95 or better mask since you could use any number of tubes of caulk and still not get plywood to seal like injection molded plastic. Anything that looks this straight forward must be a trap so I thought I would ask. If figure the cons (that I know of): Not as good seal, need to use with N95 or better mask in well vented place. My co-workers setup was for the most part sealed with a shop vac for dust control. Will leak sand, I have been told by people at White Sands NM and who were deployed to the middle east that the sand finds a way in or out. Need to fab the glove box so you don't end up taking off a few layers of skin.

-

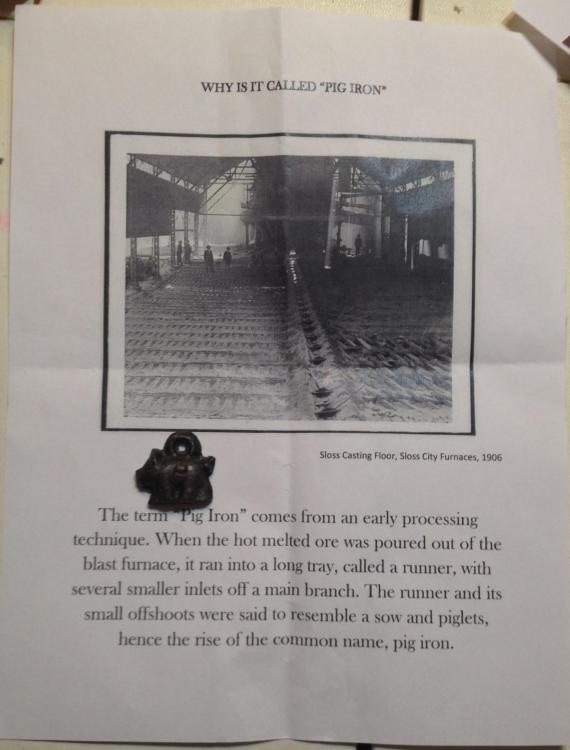

My daughter went to the historic Sloss Works in Birmingham AL a few weeks ago and got a charm in the shape of a pig that was cast from pig iron. I think it is very neat and thought I would share a photo of it. Also we are going to help a co-worker fix his ceiling after falling through it last week. I made him a tee shirt (after my other co-worker that knew him since 9th grade said "go for it") for the occasion.

-

Clontz tire hammer build

eseemann replied to Musky50's topic in Power Hammers, Treadle Hammers, Olivers

A YouTube video on how to upload YouTube videos, how self referential. -

I found some plate steel full of Hardy Holes

eseemann replied to eseemann's topic in Blacksmithing, General Discussion

Understood, I think I should reinforce with thicker stock just in case that is needed. -

Good to know, I have a nephew that has a buddy and they watch the King of Random on YouTube and want to build all sort of things like a DIY Plasma cutter and carbon arc welder from stuff around the house. This is the guy that plugs a single wire in to two different 110v outlets to get 220v. These outlets are in his house, where he lives and when I say wire I mean take the type of 3 conductor wire from Home Despot and strip one conductor. And just in case this has not been said, you might want to post your location. People can't turn you on to the good scrap yard action if you don't know what state you live in.

-

Clontz tire hammer build

eseemann replied to Musky50's topic in Power Hammers, Treadle Hammers, Olivers

Looks nice, good idea to make something for the wives too. -

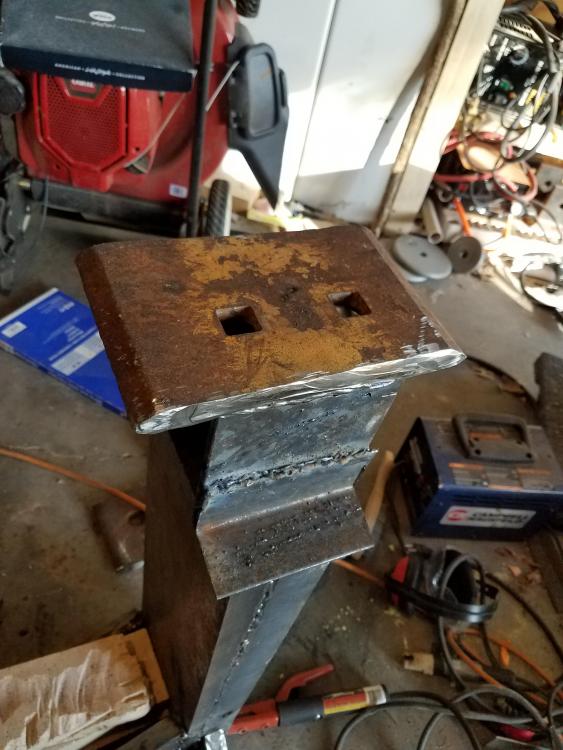

Good Morning All, I have completed the rough weld of my Nephew's forklift tine anvil with the grader blade hardy hole. Thanks to everyone that has helped me out with this. I doubled up the hardy plate so it is 1.5" (+/-) thick. I did not know how thick to make the gussets so I used 1" thick mild steel plate because I had it on hand. I can't tell you how heavy this is without some measurements and some math but I can say it almost broke my 80lb max luggage scale. Thanks again for the help.

-

Now we know what the Coyote did with all the anvils that did not hit the Rode Runner!

-

One more thing, PLEASE for the love of Dog don't make videos welding w/o gloves. I know that some people will do what you are doing here and just make a few welds but there are many people that will look at that and think welding bare handed is OK. I have seen ads for welding equipment showing what can only be described as "beef cake" models welding in a tight fitting black tee-shirt to try and convey the same type of message as the Marlboro Man. "Look at this guy, he is a Man's Man!" People will see your video and identify with you and want to emulate you. I liked the video and you seem like an approachable type people can identify with. That means you have a responsibility to act in the safest manner you can. Overall good video but listen to the people here they have seen many many things. Ernest

-

Clontz tire hammer build

eseemann replied to Musky50's topic in Power Hammers, Treadle Hammers, Olivers

Now that is purdy! I love it. Is there a spring inside the green buffer at the linkage? If you feel like posting a video of it in operation I would not mind seeing it. -

I found some plate steel full of Hardy Holes

eseemann replied to eseemann's topic in Blacksmithing, General Discussion

Good Evening folks, I have welded up my first crack at a portable hole using the grader blade and some I or H beam. I have not yet invoked the power of a grinder and some paint to make this welder what he ain't but I am pleased with how it came together. The big question is if this I or H beam will provide enough support once bolted to a stump to be used as a hardy hole. Have a good night. -

I found some plate steel full of Hardy Holes

eseemann replied to eseemann's topic in Blacksmithing, General Discussion

I might just take you up on that. thanks -

I found some plate steel full of Hardy Holes

eseemann replied to eseemann's topic in Blacksmithing, General Discussion

Beats me, all I know is it is hard! -

I found some plate steel full of Hardy Holes

eseemann replied to eseemann's topic in Blacksmithing, General Discussion

Buzz, I will do so before and after. -

I found some plate steel full of Hardy Holes

eseemann replied to eseemann's topic in Blacksmithing, General Discussion

Well folks I found the chart for welding AR steel and as long as you don't mind zooming in or have a 50" monitor you may find this useful. http://www.hobartbrothers.com/news/240/523/Three-Common-Challenges-of-Welding-Abrasion-Resistant-Plate-and-Their-Solutions.html I have some I-beam and c-channel that I might try welding this stuff to and according to this site I need to pre-heat to 200 degrees and according to this site I should be able to use 6010 or 7018 rods. This plate welded on to some I-beam would make a nice portable hole one could bolt to a stump or some such. Now all I need to do it get the stuff cut. I had some almost dead band-saw blades for my portaband and a 5 inch cut took the best one from "mostly dead, a little alive" to dead dead. Next stop is the plasma cutter! Thanks for the help.