-

Posts

238 -

Joined

-

Last visited

-

What did you do in the shop today?

Arthur210 replied to Mark Ling's topic in Blacksmithing, General Discussion

Thanks. Fibulas of this type are fairly easy to make, and good practice for a variety of twists and textures. It can be, but it's not always practical. In this case, since they are not perfectly circular (because of the omega shape), a tighter bend would limit the wearer to a single angle for the pin. Indeed. There are basically 3 types of fibulas: penannular, bow and plate. Of the penannular type, the Omega style is the most common. Bow fibula are shaped a bit like an oversized safety pin. Plate fibula are basically made like modern brooches, with a spring needle under a decorative plate shaped like an animal or an abstract design/shape, and often embelished with precious metals or stones. Fibulas date back to the bronze age. Even during the iron ages, they were often made (partially or completely) from bronze. -

What did you do in the shop today?

Arthur210 replied to Mark Ling's topic in Blacksmithing, General Discussion

Last Saturday, two more penannular fibulas (also known as Viking or celtic brooches). Made from 5/16" square bars. -

What did you do in the shop today?

Arthur210 replied to Mark Ling's topic in Blacksmithing, General Discussion

Very nice! Yes, I remember reading that forged hair pins are usually considered too heavy. The one I made is from 1/4" stock, so I don't expect it to really be useful as a hair pin. It was more of a test piece on reverse twists (those were the first I made and thus uneven) that I turned into something potentially useful, if only for display. -

What did you do in the shop today?

Arthur210 replied to Mark Ling's topic in Blacksmithing, General Discussion

I think he was referring to the hair pin at the bottom of the second picture. Of course, I called it a hair pin but it could also be used as a chopstick or a magical wand. -

What did you do in the shop today?

Arthur210 replied to Mark Ling's topic in Blacksmithing, General Discussion

I was able to spend some time is the shop yesterday and this morning. Made a few things the were new to me. First, a pair of simple penannular fibulae (for scale, they are 3" wide): Then this morning I practiced making reverse twists. Turned the first few experiments into two pendants and a hair pin. Then made another fibula: Very satisfied with them. Learned a lot and nice results. -

What did you do in the shop today?

Arthur210 replied to Mark Ling's topic in Blacksmithing, General Discussion

-

What did you do in the shop today?

Arthur210 replied to Mark Ling's topic in Blacksmithing, General Discussion

Very nice! Good(s) job! -

What did you do in the shop today?

Arthur210 replied to Mark Ling's topic in Blacksmithing, General Discussion

Just finished fabricating a number of tools for the shop last night, made over the last 2 weeks. First a portable hardy hole, because the one on my anvil is uneven and slanted, and I did not want to have to remake all my tooling if I ever decide to change my anvil again in the future. The surface is welded together from pieces of 1.5" x 3/8", the hole is 1" (to fit square tubing that I'll use for tool stems) and the legs are filled with sand. Then I made a pair of tolls that should make shaping spoons and the like much easier. And finally, a small guillotine tool (for 1" x 1/2" tools), also welded together using 1.5" x 3/8" bars. My welding is getting better too! Looking forward to the next time I light up the forge. Probably not today, it is rather chilly at -13 Celsius. -

What did you do in the shop today?

Arthur210 replied to Mark Ling's topic in Blacksmithing, General Discussion

Made a few changes in the way I make small split cross pendants. New batch took me half the time of the last one. Still experimenting with the size of the split and general proportions. -

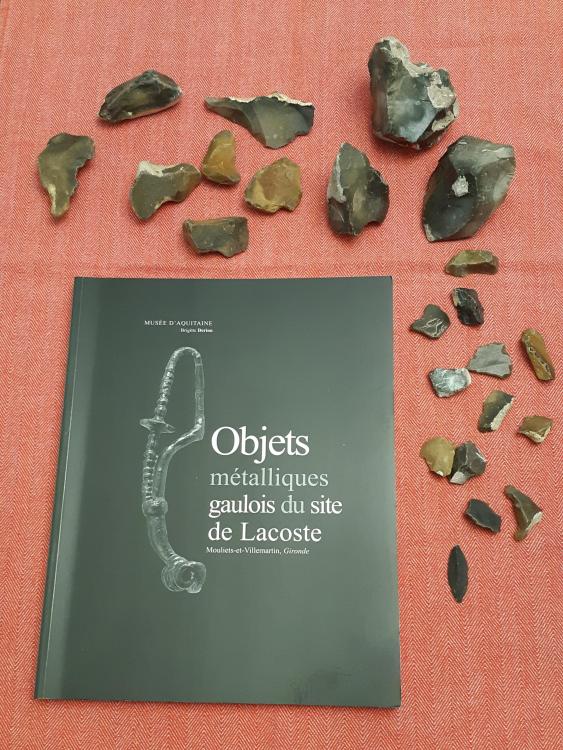

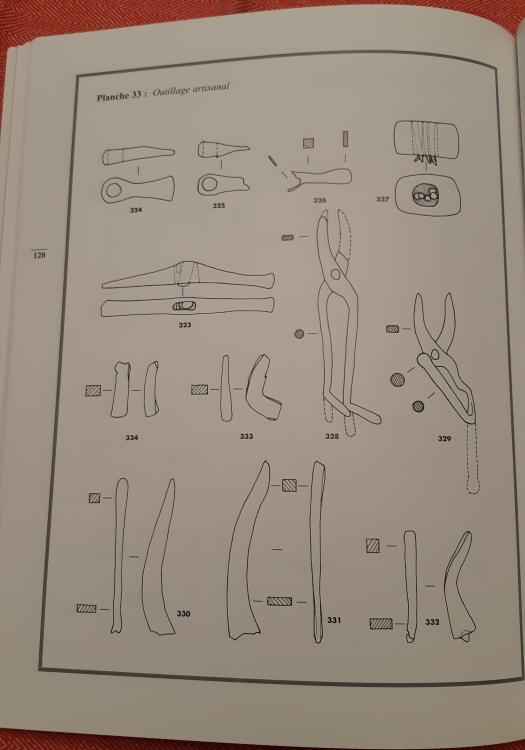

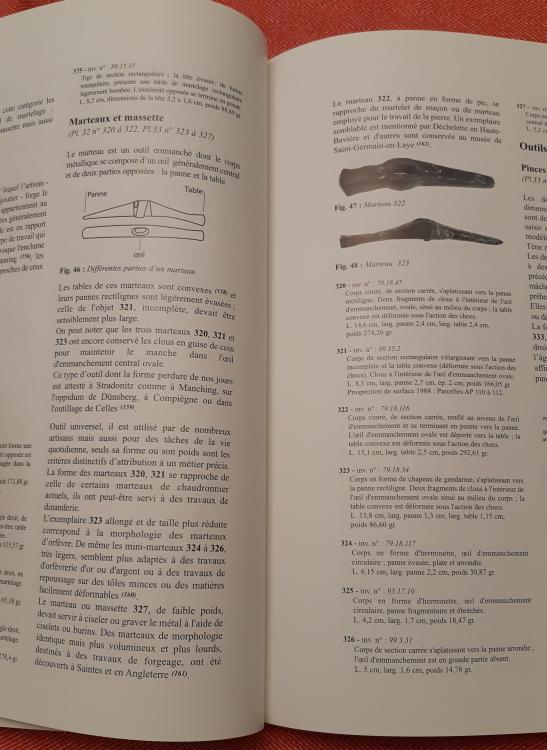

Followed me home from my trip to France. The title translates to "Gaulish metallic objects from the Lacoste site". Quite similar to the Mastermyr chest find, but much larger. And some flint from the Perigord region. The stuff is everywhere.

-

What did you do in the shop today?

Arthur210 replied to Mark Ling's topic in Blacksmithing, General Discussion

Actually, I'm keeping the collar for the next tool I plan on making, namely a bick. Felt it would need the shoulder more than the hot cut. -

What did you do in the shop today?

Arthur210 replied to Mark Ling's topic in Blacksmithing, General Discussion

The edges of my hardie hole are pretty rounded. Nor straight, and slightly twisted. The previous pictures are a bit deceptive about the width of the shoulders. I still wish I could have upset the stock more, but I don't think it will be a problem, particularly for cutting hot steel. -

Arthur210 started following Meeting a member in France?

-

I am travelling to France in September, and I was wondering if there are any smiths here who live in the Bordeaux or Périgueux region. It might be fun to visit a forge while I'm there. Do you know someone? - Arthur

-

What did you do in the shop today?

Arthur210 replied to Mark Ling's topic in Blacksmithing, General Discussion

Hardy hot cut, made from a short section of jackhammer bit. That was some though material to forge by hand. I decided not to harden it -- better to have to resharpen it than risk damaging a hammer face. The golden hue is due to the beeswax coating. -

A collection of improvised anvils

Arthur210 replied to Charles R. Stevens's topic in Anvils, Swage Blocks, and Mandrels

Thanks Daswulf. I decided cross brace would be overkill, since this is for fairly light work. I also felt that they might get in the way. And I can always add them later if I change my mind! Tried it out this morning. Works well, although it is a bit on the low side for me, but that's ok for the work I will be doing on it.