-

Posts

92 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by loneronin

-

Saturday morning after many months of searching I found this old fatter. I paid it just 1€ and the face was quite good but the botttom was badly mushroomed. I started grinding it but I discovered that there is a crack... it doesn't seem too serious anyway. what should I do? weld the crack and grind it again to close it?

-

I bought this hammer head (it seems new to me). 2.5 kg. I would like to round its faces, one more than the other, put a handle on it and use it at the forge

-

I found these tow pieces of steel... they seems shear knives to me. in this case it should be K720 steel, ideal for my forged knives.

-

I bought them at "balon" the largest outdoor market in Europe. it iake place here in Turin every Saturday morning.

-

-

My forklift anvil hack and stand

loneronin replied to clenceo's topic in Anvils, Swage Blocks, and Mandrels

...you could also rotate the picture -

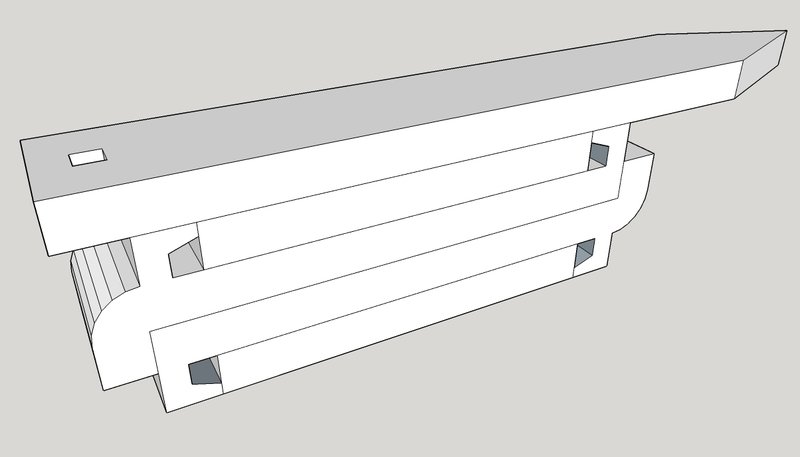

today I cut a piece of one of the forklift. I needed a couple of cutting disks but in the end I succeed. then I grinded the cut. I like it. I need to find the way to Today I cut one of the two forks. it took me two discs but in the end I won. then I grinded the cut- I like it. I have to study a way to attach it to the stump. I would like to be able to attach and detach quickly to not let it outdoors. it would not hurt being able to lay it down in different positions to use the plan or the curve or on its side to use the "hooks" that I could turn into square or polygonal holes to attach various tools or even vertically to have greater mass under the hammer.

-

Can you please make a sketch to show me how you would ct and use them? yes, that's perfect but it is way bigger than mine and I don't have that round stock at the end of the tine

-

thanks for your replies! yes, Goro is right, my idea was to add some mass under the hammer but it is quite complicate and maybe less effective than cut each fork in two and use the four pieces as 4 anvils... I'll keep the welding in stand-by and try to hammer on the forks cut under the bend... then I'll decide if I really want to weld an anvil.

-

I recovered these two forklift tines heavily damaged. they are 35mm [1,4 inch] thick (maximum), 100mm [4 inch] wide, the vertical piece is 500mm [20 inch] long and the fork is 1.200mm [47 inch] long. the steel should be AISI C45, already hardened. my plan is to cut them into pieces, overlap, weld them together and make an anvil. a challenge with the tooling at my disposal (115mm angle grinder and welding hobby inverter). is a good idea?

-

this is my anvil on the new cherry chunk. it is stainless steel (maybe AISI 316 as it was a buoy weight) not hardened. it is shiny but not so hard as you can see in the second pic. may I weld a hardened C45 plate on it? or what can you suggest me to have a hard face to hammer on???

-

yes but I need a bolt tong now. I'll go for them

-

today I made my first pair of tongs. not so beautiful, and I should have used a bigger diameter material but they woks and hold well a blade on the anvil. when I'll make an other pair of the same kind, I will make them slightly bigger. now let's see how long they will last.

-

wao! what a pile!

-

a beatiful Caber drill press. it's a professional, hi quality, hi precision piece. this model was made in italy between 1955 and 1968. It is perfectly preserved with the sole exception of the drill table which was slaughtered. but the mechanics are perfect due to the exceptional build quality. all the components are original. I'm estatic.

-

this is mine.

-

what do you think about these scaffolding foot to fix a damaged/worn screw?

-

I clean it up and paint it with linseed oil! :D

-

this is my post vise. I bought it today for only 22€. it seems almost perfect! now I have to set it up. probably I'll go with a car rim because I need to move it from inside (shop) to the outside (forge)

-

you're right. the eye is not angled... well that's the best I can do by now but I hope the new balance of the hammer will help me to have a better feeling and a little more control on my blow. this is the aim of my modification. thanks everybody for your encouragement!

-

I decided to modify an hammer in the japanese style forging hammer. I had an old 1500gr. (3.3 lbs) cross-peen hammer already modified by its former owner. I cut off the peen with the angle grinder and the jacksaw. the ugly cut has been ground flat. the face has been also fattened and beveled with files and all the hammer, head and handle, has been sanded to 120 grit, I also glued up a crack in the handle and paint it with a couple of coats of wood primer. now it weights 1150gr. (2.53lbs) handle included and... I'm definitely pleased of my new forging hammer.

-

both are beatiful. but the first one is unbelievable!!! clean design, perfect realization. I really love it! (I saved the picture for my collection)

-

ok, ok you all convinced me, I'll see a good doctor for my bad ideas.

-

yes, you're probably right. not a great idea :mellow:

-

I was looking at a "one brick forge" on another topic and I thought I can build one and, when nobody sees me, use a cooker of my kitchen (without the flamebreack) to heat it. what do you think? am I totally mad? do I need a straitjacket? B)