clenceo

Members-

Posts

45 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

coating soft fire brick outside with fire clay slip

clenceo replied to eseemann's topic in Insulation and Refractories

At some point in time will you share your vast experience and help the original poster with his question? -

coating soft fire brick outside with fire clay slip

clenceo replied to eseemann's topic in Insulation and Refractories

As for "holding up well" I've had this forge running about 2 hours at a time until I ran out of propane (20lb) The brick is not cracked, nor showing sign of degradation as of yet. The original poster acquired brick, was wondering about cracking. Please explain how other folks didn't know their gas forge wasn't working well and what to look for. That would help me a lot. -

coating soft fire brick outside with fire clay slip

clenceo replied to eseemann's topic in Insulation and Refractories

I've been using hard brick for base and walls and soft brick for the roof. It's easier for me to bore out a hole for burner flare. Check out my build... I made a frame for the soft brick. It's snug, but holding up well. https://clenceo.imgbb.com/?list=images&sort=date_asc&page=1¶ms_hidden[userid]=kbD¶ms_hidden[from]=user -

You can check out my rectangle brick forge design. https://clenceo.imgbb.com/?list=images&sort=date_asc&page=1¶ms_hidden[userid]=kbD¶ms_hidden[from]=user

-

Finished up my forge a few days ago. My idea was to create a simple forced air forge that can be broken down, easily serviceable and that can be easily duplicated if needed, and maybe manipulated for different types of materials I may be adding into it. Some things that I was able to do at my place of employment was TIG weld some stainless steel nozzles. Although I'm no expert in welding, I have been allowed full access to weld since apparently I have a steady hand. You will see my first attempts to TIG weld stainless steel below. I hope my photos are self explanatory, but if you do have questions....Please ask. I'll do my best to answer any questions. I also numbered the pictures in order....for some reason the file host does not organize them in order. I'm learning here, so please do not take offense if I can not offer a reasonable explanation. Click on the link below to see pictures! https://clenceo.imgbb.com/?list=images&sort=date_asc&page=1¶ms_hidden[userid]=kbD¶ms_hidden[from]=user

-

Hello All!! Finished up my forge a few days ago. My idea was to create a simple forced air forge that can be broken down, easily serviceable and that can be easily duplicated if needed, and maybe manipulated for different types of materials I may be adding into it. Some things that I was able to do at my place of employment was TIG weld some stainless steel nozzles. Although I'm no expert in welding, I have been allowed full access to weld since apparently I have a steady hand. You will see my first attempts to TIG weld stainless steel below. I hope my photos are self explanatory, but if you do have questions....Please ask. I'll do my best to answer any questions. I also numbered the pictures in order....for some reason the file host does not organize them in order. I'm learning here, so please do not take offense if I can not offer a reasonable explanation. https://clenceo.imgbb.com/?list=images&sort=date_asc&page=1¶ms_hidden[userid]=kbD¶ms_hidden[from]=user

-

Good evening Mikey! Thank you for taking a look at my forge. I have tons of photographs on my build. I recently used fire cement rated at 2700 degrees, and it started blistering! I would love to post my forge on the Forges 101 thread, but I'm uncertain of the permissions nor do I want to step on toes. I'm a novice in the forge arena. I think what I will do is create another thread describing my build and maybe a moderator can move it to the Forges 101 section? Once again, thank you!

-

Hello All!! Had a chance to fire up my new forced air forge. I used 1" black steel piping and a stainless steel flare that I TIG welded. Fuel pressure set to around 4-5 psi and used a shop vac for now. Seems to running well to me. Any suggestions/criticism is welcomed! Thanks!

-

Hello everyone... I have access to these pump bearings. I tried looking into the type of bearing steel it is and whether its case hardened or not. I had bearing material that wouldn't harden before, not even in water. I came to the conclusion that particular bearing may be case hardened. I know there's better steels out there, but I like to understand what I have. The make of this current bearing is from: SKF 7315 EXPLORER. I cut the race off, the balls are about 1" in diameter. I then cut a piece off the race, hammered to about 1/8" thick. I quenched in water and it broke in half pretty easy. I am curious about the grain structure...its very coarse. To those with experience, does it have significance? If I wanted to make a blade with the race, would it be usable? Thanks for any input! I think I may have found my answer. The grain structure very much looks like the one pictured in this link: http://reidonline.org/bladesmithing/intro/normalizing.htm I'll continue to experiment and have fun! If there's additional input...feel free. Thanks

-

Lets see you Henry Wright Anvils!

clenceo replied to clenceo's topic in Anvils, Swage Blocks, and Mandrels

Awesome!! Are we the only two??? -

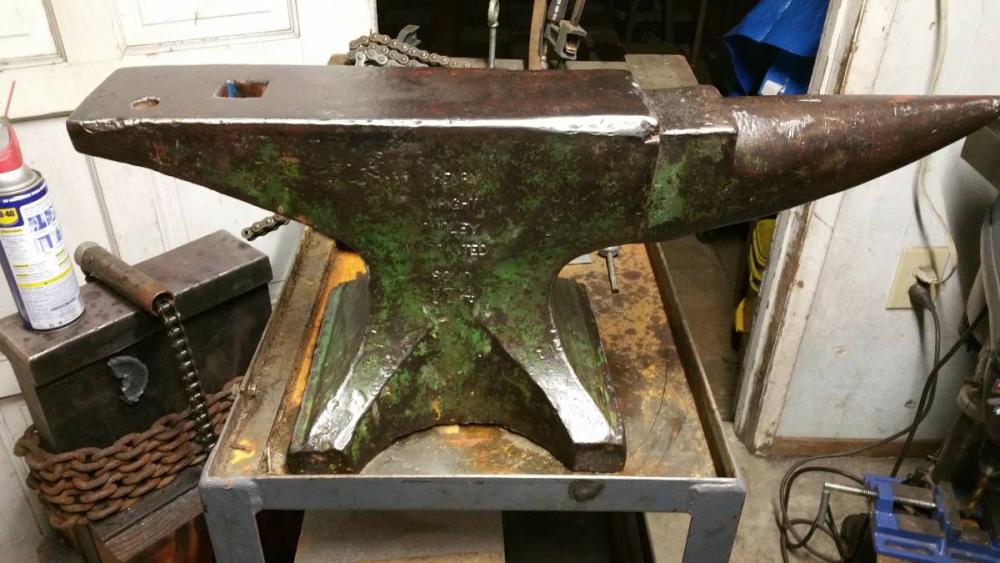

I recently acquired 2 Henry Wright Anvils. The green one is 175lbs. The owner stated it was his grandfathers. After his grandfather passed away, his father inherited it. After his father passed, he started cleaning out the farm and came across the anvil in the field. Now, he's in his mid 60's & has no use for it. I took it off his hands, cleaned up the grime and I think it's lovely. The second Henry Wright is 235lbs. The owner didn't know where his buddy acquired it from, but did a trade. He never used it and decided to sell it. I picked it up!! I like it!!!

-

Need opinions from Anvil Pros

clenceo replied to clenceo's topic in Anvils, Swage Blocks, and Mandrels

Thank you for your reply. I'm a novice, but finding my self searching for anvils every day. I feel an emotional attachment to each one I come across and curious about the history. This one I picked up belonged to the gentleman's father that passed away several years ago. I found it laying in the field, but remembered his father using it. My intentions with this anvil are not for heavy usage/abuse. I have my forklift fork anvil that I made for heavy fun stuff. I just want to insure that I can dress the edges of the anvil, and prevent any of the cracks from walking. -

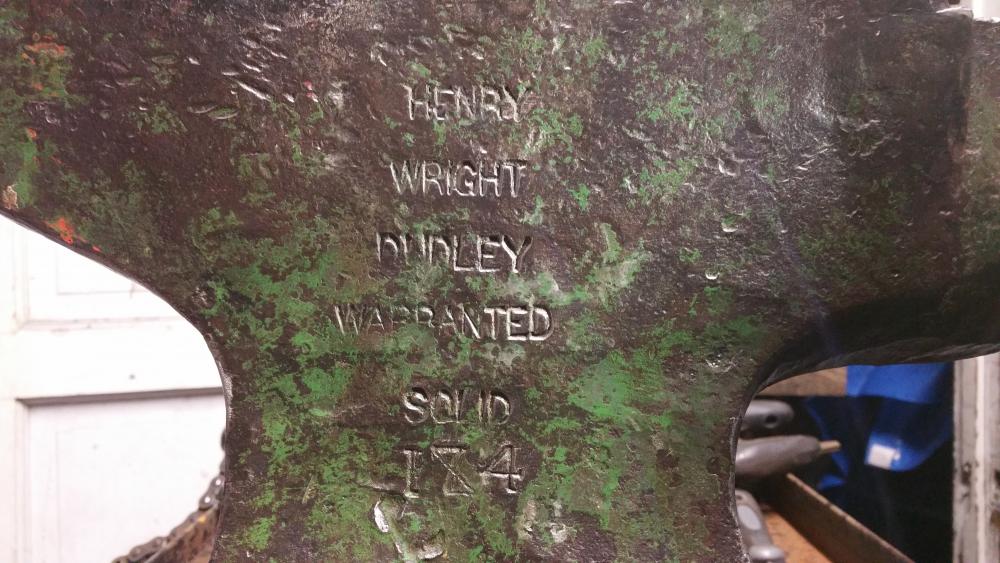

I picked up this Henry Wright Dudley anvil a few days ago. I used a wire wheel to clean it up. A few questions.... at the base, there's the #5 stamped on the corners. Any significance? Also, I'm concerned about de-lamination. I lightly smoothed the edges to remove any sharp corners. But, there is one area that looks cracked. I don't want to blindly grind away without consulting more opinions. Overall, I think it's a very well preserved anvil. Thanks for looking!

-

Hello everyone...need some anvil expertise. I located an anvil about an hour away from me. The gentleman indicated it's a Henry Wright- OAL: 28" Face Width: 4.5" Height: 11" with the numbers 174 stamped on it. My guess is 174lbs. But, I have come across information that Henry Wrights also used the English Hundredthweight System. Can someone please verify. Thanks!

- 2 replies

-

- henry wright

- peter wright

-

(and 1 more)

Tagged with:

-

Ah yes! Cold tank..thank you! I didn't think about that. Im in California @ sea level. Today 54 deg. F with a light breeze (68% humidity) After I bumped up the pressure a bit, it seemed ok. I'll try again tomorrow with some water surrounding the propane tank. Thanks again!