-

Posts

1,079 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by LastRonin

-

I agree with what I have seen a lot of the senior and most experienced smiths I've seen on here post many times... a good heavy chunk of steel with a decent size and flat face will outwork a typical ASO any day.

-

I take it you don't mind sleeping there? :D

-

My forge and the first thing I have made

LastRonin replied to Reverend Boxcar's topic in Blacksmithing, General Discussion

Hmmm, I see it too now. Maybe on the next one, use a sharp chisel and tap in some whiskers to cement it -

My forge and the first thing I have made

LastRonin replied to Reverend Boxcar's topic in Blacksmithing, General Discussion

Cool idea on the oyster knife. I like the skull on the backend. Coal or Lump Charcoal like Neg suggested would do better. I use coal in my homemade forge, and it'll burn away the steel if I'm not careful. I would suggest either making some sort of ash dump that swings, or do what I do and set it up so that the bottom of your pipe goes a few inches down into a 5 gallon bucket of water without a cap of any kind. the water blocks the air from being lost out the bottom, and lets any ash or clinkers sink to the bottom. No opening a cap that'll undoubtedly rust into place to empty clogs. Plus... if you get a build-up of flammable gases in your tuyere(?) that ignites, it will likely lose much of it's explosive force bubbling out the bottom and send less searing coals into the air out of your firepot. -

Make friends at the scrapyard

LastRonin replied to Jugornot's topic in Blacksmithing, General Discussion

Wanna be my friend? Wish I lived closer... I am having a dizzy of a time getting my hands on a post vise at anywhere near a reasonable price. -

I really like it.

-

Looks great. Since it was for stage 'use'. Why not use naugahide (sp?). You know, the fake leather they use on cheap furniture. Fake shield, fake leather... makes sense to me.

-

I found an anvil...sort of

LastRonin replied to Everything Mac's topic in Anvils, Swage Blocks, and Mandrels

What size hardy holes do you have in your anvils? You might could use a portaband to cut it down to fit easier than grinding. Especially if it is mild. -

Box Hardware Inspiration

LastRonin replied to Ridgewayforge's topic in Blacksmithing, General Discussion

What do you plan to do with the box? Is it to be functional, decorational...? -

Iron Stand - A Beginner

LastRonin replied to PeregrineStudios's topic in Blacksmithing, General Discussion

DARN YOU FROSTY! ;) Now I have ANOTHER skillset on my "I'm working on that." list. I did my first attempt at chase/repousse last night... it's barely recognizable as a representation of the original image. LOL Here it is... > -

-

Iron Stand - A Beginner

LastRonin replied to PeregrineStudios's topic in Blacksmithing, General Discussion

ThorsHammer82 may have been talking about the programming for the game. The more details you put in each item it has to image the more load you put on the graphics systems. -

Iron Stand - A Beginner

LastRonin replied to PeregrineStudios's topic in Blacksmithing, General Discussion

In a log cabin or such it would be completely reasonable to do the simple nail-point version. But most people nowadays have sheetrock walls where such mounting isn't practical. I was referring to producing an item that would be more likely to sell (i.e. have a wider prospective clientele). I agree that a historically accurate item would most likely have been K.I.S.S. engineered. But most people nowadays aren't wanting historical authenticity as much as just the "feel and vibe". -

Iron Stand - A Beginner

LastRonin replied to PeregrineStudios's topic in Blacksmithing, General Discussion

I agree about the reflector, plus it would allow hanging it instead of relying on having to nail it into the wall. That's what it looks like the ones in the game represent. The stem just comes straight out of the poles or walls. -

Iron Stand - A Beginner

LastRonin replied to PeregrineStudios's topic in Blacksmithing, General Discussion

Or you could go even safer and use the battery powered fake candles they sell for jack-o-lanterns. -

Home build induction heater

LastRonin replied to Daniel.85's topic in Induction Heating, Oil forges, etc

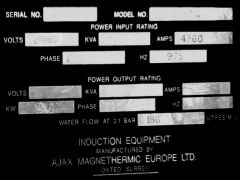

I know this isn't normally used for forging, but it will reach forging temps if the material is left stationary for more than a few seconds I'm told. '> It's used on 48" diameter pipe for gas pipelines. They have a couple slightly smaller units for the smaller pipeline pipes, 36" is the smallest I believe. '> Stats: Input Volts= 2135 VAC Frequency= 975 Hz Current= 4360 Amps Waterflow= 186 L/Min Output= 2700 KW '> Image contrast adjusted to clarify stamped figures. -

-

-

-

Iron Stand - A Beginner

LastRonin replied to PeregrineStudios's topic in Blacksmithing, General Discussion

Thanks Weltall. Frosty: Using the glass cup or oil lamp would severely limit the size and shape of the horn that could be used, but if you can be picky about the horns you get, then that does sound like an excellent idea. Oh yeah... I still play tabletop RPG's. Everything from D&D to Star Wars to Champions (a superherogame) {The entire list is too long to type here}. We have a small group of friends we play together with... it's our version of "Poker Night". -

Iron Stand - A Beginner

LastRonin replied to PeregrineStudios's topic in Blacksmithing, General Discussion

@ ianinsa : Thanks. -

Iron Stand - A Beginner

LastRonin replied to PeregrineStudios's topic in Blacksmithing, General Discussion

Firstly... Thank you. As far as the candle... If I used a wax candle I would fill in the majority with either plaster or silicon and then form a thin cup of sheetmetal to fit in the horn to set the votive candle in it. But what I am going to do is seal the small holes in the side and the end where someone drilled it for either a mouthpiece or to make a powderhorn (not sure which) and then shape a piece of brass plate to fit down in the horn about an inch below the lip, drill a 5/16" hole in it, insert a glass wick tube and wick and make it an oil candle. The legs are square tenoned from the inside. Unfortunately when I heated the collar and hammered it to adjust it's fit better for the specific horn I had, it loosened the tenons, the legs wobble when you are holding it but sit stable when it's on a flat surface. BTW, the job took me (a novice metal masher to say the least) about an hour and a half. I'm sure the time will decrease with experience. This was my very first tenons and the whole project was very fun.