IForgeIron Blueprints

Copyright 2002 - 2007 IFORGEIRON, All rights reserved.

BP1007 How to use the Hot Cut

by Uri Hofi

Cutting on the HARDIE is an operation that We often use!! We use it to cut off a finished element. To prepare the steel for the next step or to incise the bar and proper it for a tennon.

In many smithies they use two types of hardie and some times more. I use only one hardie for all the operations. I am going to demonstrate the three basic methods I use.

THE TOOLS: ANVIL HAND HAMMER,HARDIE

THE HARDIE Is forged out of a lorry rear axle and this steel is good for cold and hot cutting. The HARDIE is 3" high and 1 1/2" and more wide

Ground sharp to 30 degrees

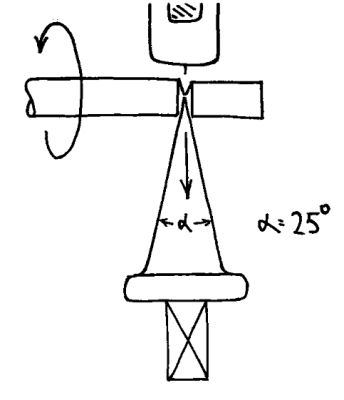

FIRST CUT

You lean on the hardie in the place you want to cut parallel to the floor and 90 degrees to the hardie. You hit easy with the hammer while rotating the steel the other direction from you ,until you get an even incision around. Then you hit harder while rotating until you get a very thin nipple connection in the middle.

You hit with the hammer out the piece is falling and you see the cut.

HOW WE DO IT

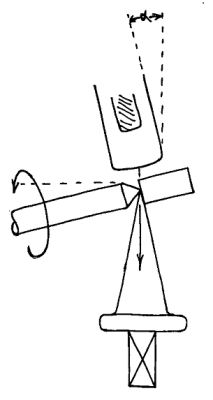

The cut before demonstrated the possibility to have square cut on the two sides but some times we need that the near side will have a point and the far side will have a straight cut.

We lean the steel on the place. We want to make the cut. We hold the steel again 90 degrees to the hardie and parallel to the floor and we forge a light incision around the steel again.

We push the steel down 15 degrees (You remember that the hardie is 30 degrees) so we push down half of it, and continue hammering while turning until we come to the center. You can see that we get a cut that the far side is straight and the near one is a short point.

We hit outside and brake the piece and we can see the final cut.

HOW WE DO IT

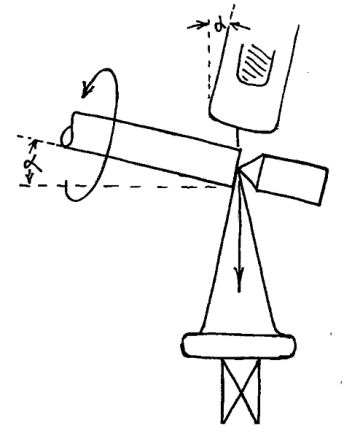

Some times when we cut we need the opposite that the strait cut will be on the near side and the point on the far end.

Then we tilt the steel up 15 degrees and the hammer too to the same direction.

Again we put the steel on the hardie on the place we want to make the cut. We incise the cut around easy.

If you stop in the middle of the process depend on the depth that you are coming too this is a start of a tennon (you do not need the "blacksmith magician" The hardie is having many more uses may be we will speak about it in the future THANK YOU URI HOFI

We go on forging and rotating until we get the thin connection and we brake it and get the final cut.

Recommended Comments

There are no comments to display.

Join the conversation

You can post now and register later. If you have an account, sign in now to post with your account.