-

Posts

203 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by rawtiron

-

-

Saw this today. Looks like he is wanting scrap value, which was around $350 a ton last week for clean mild steel plate. I have little experience with these so info on make and other specs would be appreciated. I can see a 34 on the front and the counter weight could be missing. It's a 8-9 hour drive each way from my place.

Thanks for your time, Jason.

http://www.trademe.co.nz/Browse/Listing.aspx?id=333390178 -

She looks great smithy1. Nice job.

Jason -

I like working at home, as it's close to the kitchen.

In your case, what an opportunity to move to a bigger shop!! You can never have too much space, and you get to see your grandparents every time you go there.

Jason -

This is true for me also.

-

just traded a fire poker with a little leaf on for 4 pheasant and 6 partridge at my kids school gates

Good trade Beth!! I haven't had pheasant for years. I did the same a while back for a whole lamb. And our neighbours feed us wine for the jobs they get done.

Jason -

Sure Jason anything you could provide would be helpful as these machines seem to be pretty scarce around these parts..

Larry

I'll email you Larry.

Jason -

I think there are spot riveters out there with enough ommph I think the issue would be not nuking the contacts with prolonged exposure to the rivet...

But I am kind of hoping to find someone with real experience or better yet with a machine....

I watched one in action the other day along with an old pneumatic rivet press. The owner lives here in NZ and has used it to rebuild and rerivet steam boilers for traction engines and alike. He's 80 odd years old and had plenty of experience(and only a long plane flight away ). I'm happy to get you his details.

). I'm happy to get you his details.

Jason -

Beautiful work!! And great website!!

Jason. -

That turned out really nice. It looks great!

Did you do anything to it for corrosion resistance?

Thank you Sask Mark. I neutralised in baking soda and water, and have only oiled it at this stage. After talking with others I may clear coat (incralac) it as I have done with other inside sculptures. It's fairly heavy so it will probably hang on the wall mostly.

Jason -

-

Beautiful Work!! I'm looking forward to seeing the finished piece.

Jason -

It does say on his site that the orders are about a week behind. My order took about three weeks to reach me in NZ, but all arrived safely and was at a much better price ($50 less) than I could get here. So overall I am very happy with the service and the quality and price of the goods. (fisher regulator, por fitting and gauge)

Jason -

That's a pretty piece of pattern welding! Makes me want to take a lash now.

Ah HAH! So Tristan visited you while down under! He's a good guy and has been here several times. I was hoping he'd get to meet some of you blokes I know on the far side of the planet.

He posted a bunch of Pics to the club site though I haven't gotten to take a look yet.

I'll be pumping Tristan for stories soon as I see him again.

Frosty the Lucky.

We had a great week together Frosty! Plenty of forging and a few visits to some local places of interest. (as you'll see by the photos)I have really appreciated meeting and getting to know Tristan in the short time we had. All thanks to this forum being made available.

Jason -

-

Thanks Glenn. I have been in touch with a couple of local farriers/smiths here in the Manawatu area. They are pretty busy trying to make a living, but we do get together every now and then which is great. I learn well from watching others, then having many goes myself.

Jason -

I wish there were more smiths in my part of the world like you people, willing and able to take some time to teach. I learn best with someone standing by my side.

Jason -

Jason no sooner said than done

You Beauty!! -

On a different note reference NZ

I tickled the paint off a plate on the side of a massey 2cwt clear space that revealed "Supplied by Kidd and Garrett, Auckland, New Zealand". Hence manufactured 1954 in the UK, then shipped to NZ and 40 years on shipped back to UK.

This hammer is currently running in my forge in Ireland, good quality tools are worth moving around..

Man thats done some travelling! I know of 2 or 3 other 2cwts still in use over here. I'd like to see some photos.

Jason -

Does flaring the nozzle really add that much to the performance of the burner?

These are the only flares that I have run, so I have no experience of any other way. I can have the burners ticking over at as low a psi as the regulator will allow and crank them up to 30-40psi without any issues. The flame is really stable all the way through the range.

Jason -

Hi Jason,

Thanks for all those pics. I wish I owned those machines!

Did you get to see Frosty's place while you were in Alaska? I recon his place has gotta be worth a good decco. Despite of the risk of 'harmfull trees' and dangerous looking slippers

Ian

Hi Ian,

It was a visit by another member to NZ (my place) from Alaska. I'd love to get over to Alaska some day to check out Frostys shop and Frosty himself. It all sounds very interesting!

Jason -

That massey is one weird ass looking thing, never seen one like it.

It looks like a 'clear space' but with the ram from a 'Rigby' hammer in it. Ill have my first guess that its a special 'long stroke' self contained hammer. (the serial number is an oddball aswell..)

I will look it up from the serial number next week, then all its secrets will be revealed

Thank you John. All I know is that came from the railways. (NZR). They say it weighs 11 ton, with a 5 ton anvil and is 17ft high. And that there were ones twice that size used here also. We will be visiting the previous owner this week, so I'll see what else I can find out.

Jason -

-

There's still a lotta pleasure livin in them thar hammers!

That place must just ooze with old energy!

Ian

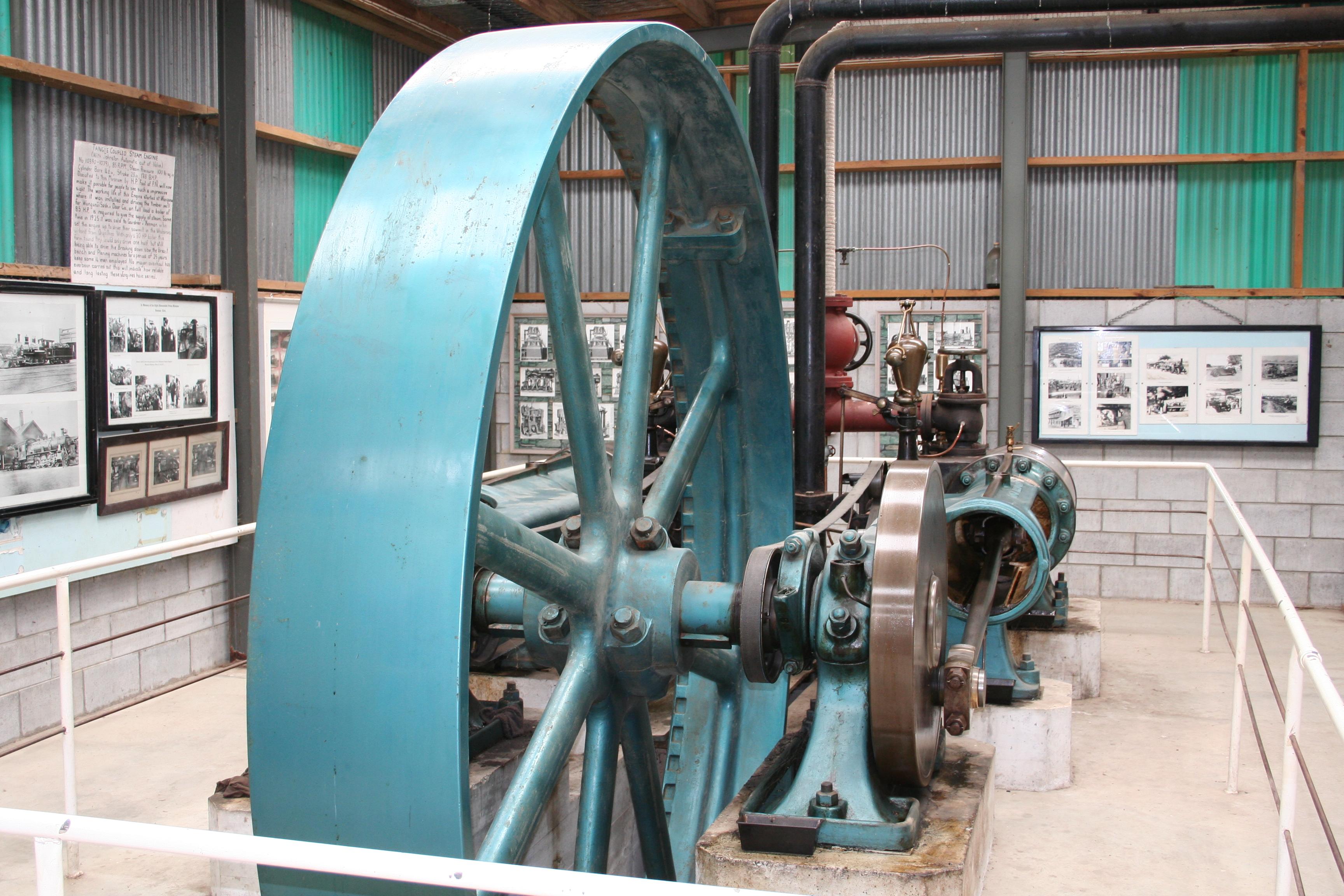

It's great to see so much old working machinery in one place like this. They are in there 41st year of operation.

I grew up near by and got my first ever job here cleaning the brass plaques and helping out with the steam train they run.

Colin was trained as a blacksmith and farrier, under his father and went on to become an engineer. He is very experienced at working the machinery he has (except that big old Massey) which is a recent purchase.

The press brake came from the Luftwaffe factory in Germany after the war. Note the bullet holes/divets in it. The brand name on the next machine should be familiar with some you. They are still operating today from what I know.

-

John Nicholson will be able to give some information on the Massey hammer. John's father worked for Massey in Manchester England until they went out of business. John then bought the rights to Massey, the drawings, etc. and has made a nice business out of rebuilding them. If I remember right, they started around the 1860's and sold hammers all around the world. Many of these hammers are still running today. I had the opportunity to visit John and his father in the old Massey factory in England and one of the more interesting things was the room where they stored the old mechanical drawings. They had the original ink drawings of all of the hammers produced... and many of them went back to the 1800's. John is active on this forum and am sure that he can add a lot more to this thread.

Thanks James. I had thought that JohnN would be able to let me know about the Massey. I was looking at the pics from your visit there, yesterday.

Jason

Fly Press

in Presses

Posted · Edited by rawtiron

What are the main differences bewteen the two Larry? Does a fly press have a flywheel type weight? They seem to be very rare over here and I have seen both names (Fly and Screw) for the same machine.

Thanks, Jason.

Ahh just looked at an old post. Fast screw vs slow screw!! I get it now.