-

Posts

535 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Chimaera

-

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Ah. Sounds like a hybrid "joy" and a PITA. Where do you generally find it? At scrapyards, but what in? -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Yeah, but now bolts aren't so hard to make... Is it tradition, or are they just not designed for it? Or is it actually worse? -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Ok. Just seems like the easiest thing you could do is throw in a bolt. And, totally unrelated. Wrought iron. What is wrought iron? It's got a weird wood grain texture. I've heard that's from silica slag? What makes it so expensive, and why do people want it? -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Hey guys- I have a question. Why don't anvils have holes in the base? Isn't the goal to get the anvil down tight? Why don't you just bolt them down? Does it ruin the structural integrity? I was just thinking about how much easier it would be if they had holes, and it's not hard to drill a hole in it. Get a good cobalt bit, go easy, no problem. Why then? -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Nope. XD -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Alright. $5 for the forge, anvil, hammers, tongs, and, why not, the house too. And a tooth hug on the house. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

BB- the customer is always right. You are correct. I am your customer now. I want your forge. I'll give you $5 for it ;). But you're right. Let 'im say what he wants -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

There are two differences- the placement of the river, and the tax laws! -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Huh. Sounds like an interesting documentary. What are those chisels made of? They seem like something I could possibly make, bad as I am. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

TP- really? The horn doesn't help with hooks? Do you just hit it sideways to break it into a curve, then? I'd think that the horn would be really helpful in getting a good curve. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Oh, I did not read correctly! I didn't even see the county, just Ross Ohio. Well, still in the general area. Nice hook, though. Love the really tight twist. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

JDinOH- nice hook. I'm in Colerain, and know several people in Ross! I should probably make a hook sometime... probably doesn't help that my anvil doesn't have a horn! -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Now that is one shiny hammer! I knew it was a jewelers hammer, but I didn’t realize how small it was until shown next to the sharpie. Cute! (If you don’t mind me saying. I know that it is an excellent tool designed for function.) What size O1 is that? -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Das- sorry if it sounded like I was upset. I was just joking, which, as we all know does not translate well through the internet. I know that you have had years more experience than me, and probably the scars to prove it. If I’m being honest, I kinda hope this one will scar up to remind me to not be stupid. On my ankle I have the reminder to listen to my mother (when I was 7, I was climbing on a pile of oyster shells. My mother told me to get off them, and I didn’t listen. A minute later, I was struggling to stand up, blood streaming down my legs), it would be fitting to have this one here. Thank you for taking the time to help out someone who’s likely to get himself killed otherwise. SLAG- sorry, I meant the epoxy wood dust blend that you suggested for filling handle gaps. Though super glue certainly is useful for minor cuts. I didn’t know it was invented for that. I generally give em a drop of super glue or a piece of electrical tape when the blood would get in the way. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Das, let me have a pity party! I know it’s nothing compared to what you guys have gone through, but it’s the worst I’ve gotten in this hobby. Let’s hope it stays that way for a while -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

SLAG, did you mean me when you were referring to epoxy? I don’t see anything from BB that that would refer to... -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

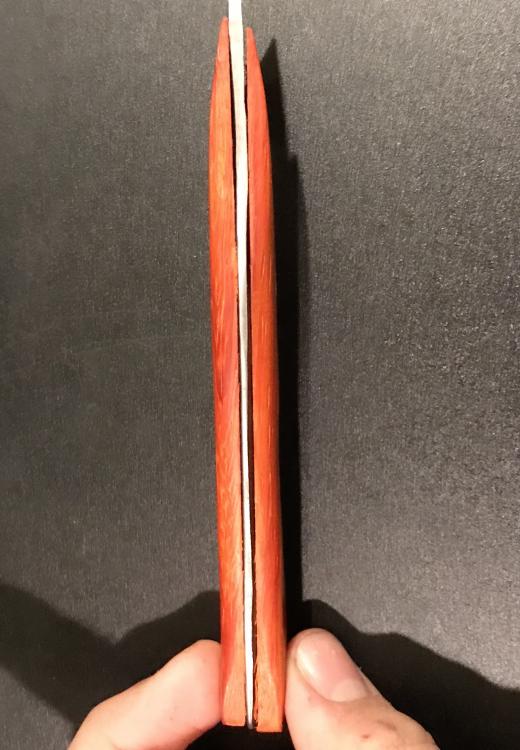

Finished! I think I'm going to keep this one... it's almost what I want to give my uncle, just not quite. The scales aren't quite the same thickness, they aren't quite flush with the tang, the blade isn't quite what I want, there's a minor crack in the handle, along with a couple dents ... so close! I think I can get it next time. Overall, though, happy with the result and very proud of my second knife. And there’s the drill press’s little kiss -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

The cut took a few hours to stop bleeding, but I’ve never had stitches and I ain’t getting them now! Just as long as it doesn’t get infected I should be fine. A gauze pad and duck tape did well. I recently got a friend of mine a HF angle grinder and dremel. I use my old man’s nice ones, as he rarely used them and can have em back whenever he wants. I haven’t broken them, but I don’t want to remember when I was a little kid and started using the dremel... dremel bits are not too robust, at least not in the hands of a 9 year old. Still hard to keep them from breaking... -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

So, I brushed off my clear coat and blue, tempered with a torch, and drilled. Boy oh boy, is that one beaut of a bit! Cut like it was nothin! Got some padauk slabs cut, and will probably finish her up tomorrow. Unfortunately while using the drill press, the clamp came off, and the incredibly sharp knife with no guard was spinning at high speed. Apparently human flesh does not deal well with spinning knives. That’s gonna take a while to heal, but at least I learned some lessons -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

I went out looking for a solid carbide bit and to no avail. I was able to find a cobalt bit for stainless steel, which I thought was better than a black oxide or TiN. -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

TP, good point. Could I do a differential temper by putting the blade in a vise (acting as a heat shield) and heating the handle with a propane torch? If not, what are my options? I know that I could do a full temper in my oven (probably will next time, this stuff wanted to chip and was a beast to sharpen), but that's not what I want. I know part of the temper is the time at heat, not just heat, so I'm not sure of anything I'm saying! I should just ask my question and then shut up... -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

I was using cold blue to color it, so I taped off the bevel (being a utility knife it has just one bevel). I gave it a clear coat (again taped the bevel) so we’ll see what happens. And thank you for your kind words and suggestions. I’m just in love with these little guys. So much function, even in an inch and a half of blade! -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Ugh. Someone I met called those “Odin’s little blessings”. Not fun. Looking back on my previous pic, I noticed the light of 11:00 in the garage isn’t great, so here’s one where you might be able to actually tell what’s going on. Any thoughts for improvement? -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Paul, that would make sense. However, with it being so light duty, I just want to call it good and be done with it. Might do that in the future -

What did you do in the shop today?

Chimaera replied to Mark Ling's topic in Blacksmithing, General Discussion

Hondo- wrap your blade in a piece of leather or a plastic bag, and put it in the vise. Take an inch wide, foot pong strip of emery cloth, put it so the abrasive is touching the bottom of the handle (where your fingers would wrap around) and pull it back and forth in a sawing motion to round the handle JHCC, it’s surprisingly comfortable, so I think I’ll just stick with the steel. It’s a light duty knife anyways, so you don’t have to have a big bulky handle to grip Definitely room for improvement, though. Next time I’m going to go for a longer(still kiridashi) blade, I think. Also try to leave more material so I can grind out hammer marks. And not HT the handle!!