-

Posts

535 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Chimaera

-

Sandblasting after hardening, blackwashing

Chimaera replied to Chimaera's topic in Finishes for Metal

No harm done. I'm glad you think I can make a living off being the worst bladesmith around ;). Tea made with rice... interesting! My only rice drink experience is with horchata... now that is good. -

Sandblasting after hardening, blackwashing

Chimaera replied to Chimaera's topic in Finishes for Metal

I'm not sure if I got that one or not on my tour... I know I got some kind of pearls, but I can't seem to find them... I like dairy in all my tea, but that CEG really needs it. I mean, generally it just makes it a bit smoother and nicer for me, but with the CEG a little cream makes the difference between mud and one of my favorite teas. -

Ok. The oxidizing certainly makes sense. It just seems like it would be the lesser evil as opposed to sticking it down in there... A piece of rebar I don't really run the risk of melting (most of the time) and I can easily pull it out and check on it. However, a timer could probably help with that. Thanks for the tip.

-

Sandblasting after hardening, blackwashing

Chimaera replied to Chimaera's topic in Finishes for Metal

Sorry to hear that. I'm glad the Irish breakfast suits your tastes. The CEG is a difficult one. With some dairy it gets such a smooth, rich flavor, but otherwise... not the greatest. And if oversteeped... -

Sandblasting after hardening, blackwashing

Chimaera replied to Chimaera's topic in Finishes for Metal

Speaking of keeping hanging: How'd they turn out? It was supposed to be a knife at one point, but then something went wrong, so I cut it off the rebar and just had it sitting around. And so I thought "rather than taking a real knife and having it get screwed up, I can use this". And no, it's not even a KSO. You wouldn't be able to tell it's knife shaped. It's like a BSO- Bar Shaped Object. Almost a bar, but just screwed up enough to not be one. I was saying that I forgot to harden it, so it could be different for bead blasting hardened steel, but I think bead blasting hardened steel would turn out alright. -

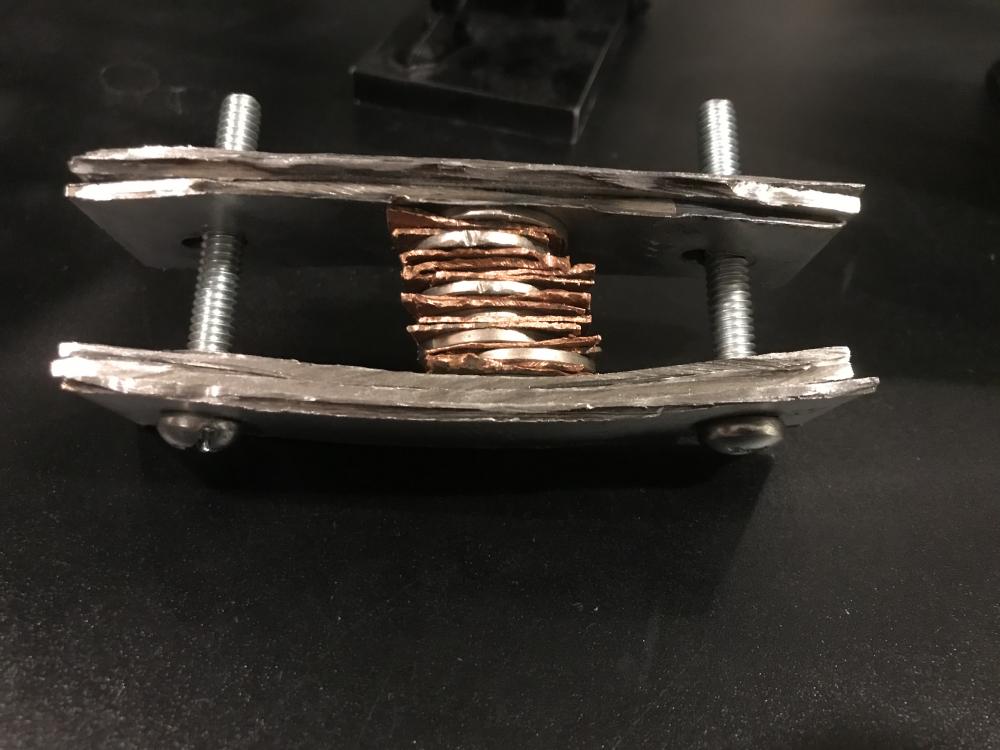

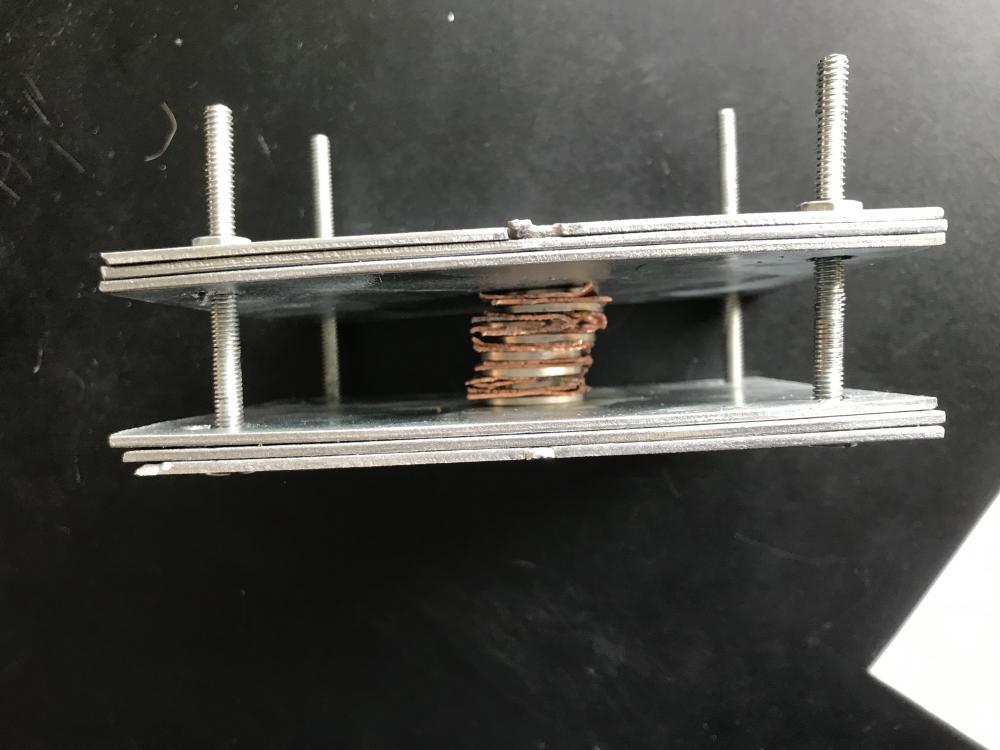

So, quick update. Thankfully, most of you (gently and nicely) prepared me for failure, as that's exactly what I did. I started by hooking up the shopvac as my air supply, which gave me an incredibly hot forge. The nice thing about that is that I then don't need to bury the mokume in with the coal, it can sit on top which lets me monitor it much better. First heat, I got it a little late. It starts to look wet, I go to pick it up, it lets out a couple drops of copper before I get it, but it seems alright. Give it some firm but gentle hammer blows, throw it back in to heat to "wet". Pull it out, firm but gentle hammer blows. At this point, the stack is beginning to lean a bit. Third and final welding heat, seems to go alright. Pull it out of the clamp, throw it on the ground, it doesn't break. Next couple of heats are just squaring it up a bit. Go to grind the rough edges off, and... cold shut. Maybe two. Try to give it another weld, one of the whole layers breaks off. throw it back in the fire, have some issues with the shopvac, and... melt it. Wow. Hopefully I learned a couple lessons. Make sure the stuff is clean and has good contact, be very careful with timing, try to get shapes that line up... I think I'll try again with quarters, they might be a bit easier for me. Quick note, has anyone had borax create clinker? I sprinkled a little borax on before round two of welding, and immediately after I got crazy clinker.

-

Sandblasting after hardening, blackwashing

Chimaera replied to Chimaera's topic in Finishes for Metal

Ah, sorry to keep you hanging! I'm still working on making a knife (made one over the last couple of weeks, but friend who was making it with me wanted scale). However, I took just a piece of scrap, used an angle grinder flapper wheel to smooth it out, and bead blasted it. Granted, I forgot to harden it, but I think it'll still work. That turned out with just the finish I wanted, matte, just slightly bumpy. Still awaiting some ferric chloride for a deep, black etch, but an onion patina turned out really nicely, so might go with that on the knife. -

The metal, rather than the coal, absorbs the heat. I'm not sure... Let's just say I'm wrong.

-

I may be wrong, but I feel that a larger piece of metal will make it heat more slowly by drawing the heat out of the fire itself (I have a very small forge that doesn't output that much heat)...

-

The plates were primarily to keep everything aligned and make it not all fall in the forge. Stressing the flatness and fresh sanding certainly makes sense. As far as the overhang, I was thinking set the weld and then immediately afterwards grind the edges smooth. Does that seem like a possibility, or am I setting myself up for failure? Thanks for your input.

-

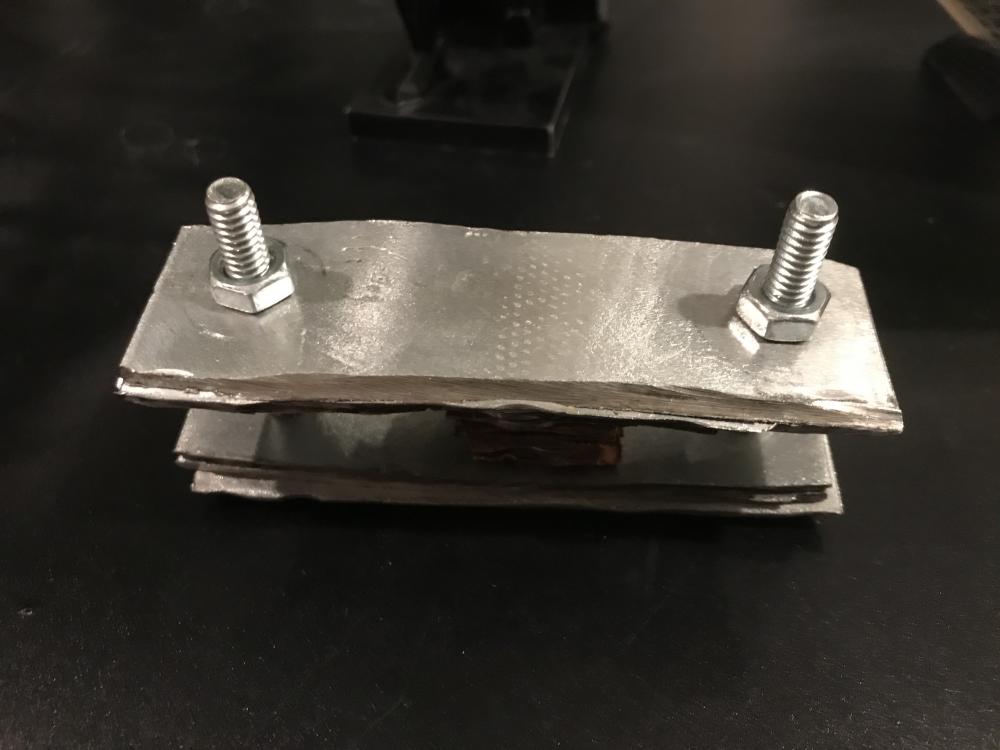

Take 4- Beefed up the screws, no more big hunks of steel drawing out the heat... I will try this before buying some 3/8 bar if I can't find any. I see how much the steel is warping and plan to loosen up the screws a bit.Any body got some thoughts on it? Irondragon, I didn't at all think about school buses! I thought about trucks, trailers, etc, but not buses. Thanks for the suggestion.

-

Yes, I didn't understand that it was supposed to have two bolts... I'm gonna cut it down to an inch wide or so. Sometimes my brain just does not want to work... I'll also try to find some thicker steel, but, since I already have it, I'll probably just try this as a prototype

-

Ok. Those are generally 5160, no? I will see if I can find somewhere that replaces them, see if they'd be willing to spread the wealth. Trust me... at the stage I'm at in my forging, people probably don't want most of my stuff as gifts... I guess I just haven't spread out as much as I need to, need to use, as Glenn said, the TPAAAT. I'm sure I'm surrounded by stuff if only I go look for it. I was more talking bronze (I can find brass pretty easy in rifle shells), and would only need sheets if I were to use it in mokume. I have another project in the works which is a bronze and padauk letter opener for my brother (he's getting a ton of college mail), which would be cast. I found a store in Cincinnati that sells bronze, along with a bunch of other alloys and steel, so I think I'm set with that. Thank you. (Rendering of letter opener) Thank y'all for your help in this, may I say it, fiasco. I've gained a lot of excellent information which I hope I have the capabilities to put to good use. Besides, it was nice to chat with some people who have a similar interest, especially in these times where you can't talk to anyone at all.

-

I really need to find some local blacksmiths and figure out what I'm doing...

-

It would seem I have misunderstood the diagram... oops. Somehow it looked like you were supposed to use 4 bolts... my oh my am I bad at this...

-

I don't have a ton of money, and (though not for lack of looking) there is nowhere within a reasonable distance that you can walk a scrapyard (other than automotive, of course.) I try to look, but I never see anything on the side of the road... After briefly searching around, it looks like I can get some 3/8X3X24" for $13... might get that. While I'd rather do this for "free", sometimes free just doesn't cut it... and I'm literally melting money anyway, so why not. Upon remeasuring (with calipers this time) my jig is 3/8" thick. If it would be helpful, I can add another layer or two to it. The bolts are really thin, and I plan on picking up some thicker ones (I can afford those) soon. The current ones will almost definitely fail after a single forging, and might even have to be cut off of the plate. As a prototype, at least, is there just the slightest possibility of this working? That's all I ask, that I have a minor chance...

-

If you've got any thoughts, though, I'm happy to listen

-

So I guess 1/12"? Weird size for a plate, so maybe 14 gauge? While you're probably correct, I don't really have another choice... It's between getting it thick, but layered, or thin... I figured the thicker one was the lesser evil

-

I'm doing three of them on either side which comes to 1/4" on either side

-

Just made this. Have to let my steel plates soak in vinegar overnight, though to get the zinc off.

-

Yep, figured it needed to be polished and have something to keep it from bonding

-

Thank you. Would silver bond to steel? i.e. could I take a small steel thing (think jelly roll pan but mini) and pour the molten silver onto that to give a smooth, thin sheet?

-

Thanks for the advice. I'd rather not mess with zinc as well. The gold dollar coins are a little expensive for me, so I'll probably stick with some copper pipe for now. I haven't really seen bronze for sale, anywhere. I really want to cast a bronze letter opener for my brother, and it would be good for mokume, so do you know where I could get that? Or would I have to make it with some copper and tin?

-

Ok. That makes sense. Does it need to be wide enough to clear the face of your anvil? So that the plates and not the nuts are touching? I can try to make that, I just need to find some plate, as the only stuff I have lying around is galvanized... Frosty, I don't have the money to buy a piece of silver, so no worries there! However, you suggest a little bit of borax? (I won't tell the purists ) Sorry for not understanding the first time around, and thank y'all for your help. I assume the plate and screw assembly is reusable? If so, I can try to degalvanize my steel and make one.