-

Posts

535 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Chimaera

-

Why did you have to go and ruin my dreams like that??? =( Just kidding. Do you have any idea how the Zinc fumes would effect it? Thanks.

-

Oof... Didn't think through that

-

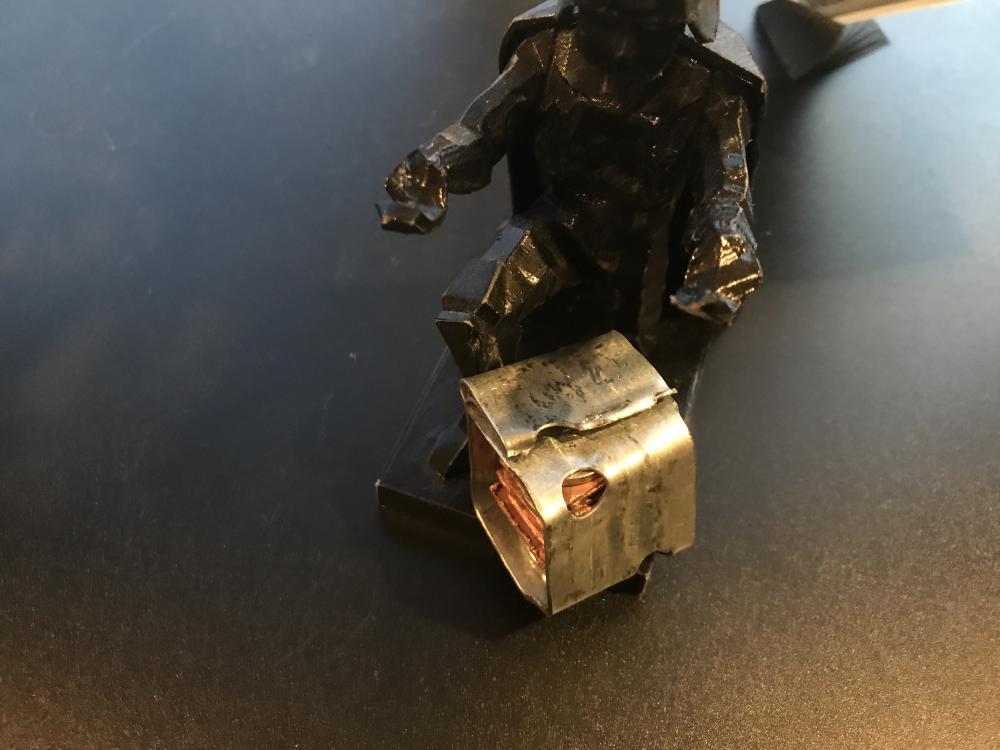

Here's what I came up with: those are alternating layers of a US nickel and a two thick piece of copper piping. Yes, the steel box is galvanized, but it's small enough that it shouldn't cause problems (I forge outside).

-

It would seem I lost something in translation... I was thinking no cupronickel sheet, but rather alternating nickels and copper sheet, as nickel sheet is xxxxxxx expensive. Your suggestion on how to use the copper pipe was more or less my plan, stuff 'em in, try to form it, crimp the ends. The steel was there as a muffle, as I thought it might be a little tricky in my sub par homemade anthracite death trap. And yes, that idea is quite convoluted, and very well might not work. I have another plan, though- I've got these 1/4"*1" mild steel bars that I could cut two 3-5" sections of, then put a pair of bolts through and a set of wing nuts on one side. Yes, it would be a monstrosity, but it could work... Then I also wouldn't need to get my copper perfectly round, which would be a huge pain. I'll probably build this setup and try this version next time I get my forge out. Thanks for pointing out the errors. That's why I like it here. While trial and error is the ultimate teacher, it's good to hear when something is just a plain bad idea.

-

I'm sure it can. I'll look for an ABANA. What I'm wondering (I'll have to look into it a bit more and then probably test) is if I could take a copper pipe, put my coins in, then put that in a steel pipe. Not only would it give a nice copper border to the mokume, but it would (hopefully) not destroy everything... Awesome, thanks!

-

Hi. I'm located in Cincinnati. I'm very new to forging, and have built myself a forge (not JABOD, weber style grill lined with fireclay). I've moved through a few different fuels, eventually settling on Tractor Supply Company Nut Anthracite at $0.20/lb. However, especially now that I want to try some quarter mokume, I've heard that bituminous/soft coal/coke works a lot better. Does anyone know where to purchase some of that in the general area? Also, what would that cost? I'm on a budget and would rather not go very far over my $0.20/lb. Is that even possible? Thank you

-

I'm telling ya, Reliant Robins are the way to go!

-

I think you mean IF... But yeah, that sounds nice... I really don't know what I'm doing, so some guidance would be great

-

Yeah, I was thinking that could be nice. Sorry, I use anthracite (only thing I can find) so that's a no go... That sounds like something I might give a shot. Do you have a Yugo? I feel like I've seen you use that metaphor before... And nope. I drive a Reliant Robin. In seriousness, I use nut anthracite from TSC...

-

Ah, ok. Your original comment made it sound like you got mokume with nickels and nothing else. I can imagine that it likes to delaminate without enough heat. I'm pretty cautious about zinc, had enough people I know get fume fever, and I've developed pleurisy after grinding, even with a respirator. Whether those were related or not, I don't know, but it hurt like heck, so I'm careful about that. I have an idea for a rig, so I'll try that... Get it really close to melting, but don't quite let it? I might try to do some later (maybe quarters, maybe nickels and flattened pipe), so I'll see what happens then.

-

Teenylittlemetalguy, You used them by themselves for mokume? How? They are a solid alloy, are they not? I'm very interested in this, as everything I've seen says that they're solid... Thanks!

-

My condolences. That's very difficult to go through, and knowing it's coming rarely makes things easier.

-

Nobody's Tom. Never said Tom...

-

Sounds good. Thanks for your help, ThomasPowers.

-

Ok. I'll maybe give the nickels a try with some copper sheet, or try some half dollars. Thank you.

-

Yeah, but I've done that to quarters and they look solid... I'll try it again later... lol

-

Ok. That's what was confusing me. I believe quarters, dimes, and half dollars are clad, so that's what was throwing me off, along with, in reference to nickels: Ok, so jerry rig some kind of bolt system to hold pressure on? SOunds good. Sorry for my confusion. Thanks so much for your clarification!

-

I agree, clad would be a better word. So, you're suggesting (just as an example) taking 3 nickels (3 thin copper layers and 3 thin nickel layers) and then a thick layer of copper piping and repeat? Or one nickel, one pipe, one nickel? I think either of those would give a very nice pattern, if that's what you're suggesting. It would have a fine nickel and copper pattern between layers of thick copper. If that's not what you're suggesting, I'm lost. How do you keep your coins together? I've seen people forming brackets and then binding with copper wire? I've seen some people putting the whole stack in a pair of vice grip pliers or a clamp. I've seen a couple people put the stack in a vice and use an oxyacetalene torch, which is something I do not have. It's just a tricky situation for me, as I have a solid fuel forge, which makes observation very difficult... It sounds like by far the hardest part is getting the first weld

-

Sorry for all my questions, I'm just really interested in how I can make such a beautiful thing on a budget...

-

Ok. You clamp them and keep the whole clamp in the forge for the first couple heats? I mean, if I melt a couple dollars of nickels, oh well. However, I'd really rather not have a puddle of cupronickel clinker stuck in my forge, and I REALLY don't want it bursting and spraying (I don't think that's a high risk with copper and nickel, but I've heard enough horror stories with titanium...)