-

Posts

448 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Paul TIKI

-

What did you do in the shop today?

Paul TIKI replied to Mark Ling's topic in Blacksmithing, General Discussion

cool Natkova. How did you do the handle? It was too windy to light a fire, So I redesigned the firepot in the forge and remembered to take pictures I had some helpers too. -

What did you do in the shop today?

Paul TIKI replied to Mark Ling's topic in Blacksmithing, General Discussion

Frazer, I chalk my problems up to inexperience mostly. However, since my anvil is improvised the shoulders are pretty rounded so I wasn't getting a clean shoulder. My two most successful leaves were done on that. I then took an angle grinder to square a portion of the edge up and it is probably too sharp, guessing by the comments I'm reading here. I also suspect I have let the metal cool too much between heats. Next time I get out there I'll play with that a little and try to remember to keep the metal hotter. I did have a couple of times I burned the steel accidentally. One time was clearly my fault. the other, I'm blaming the dog -

What did you do in the shop today?

Paul TIKI replied to Mark Ling's topic in Blacksmithing, General Discussion

I keep snapping my leaves off at the stem. I think I'm creating cracks when I try to put a shoulder to separate what is going to be the leaf from the stem. John at black bear forge did a great youtube video on it, that may help. Yours does look nice, by the way looks kind of like a bamboo leaf. -

What did you do in the shop today?

Paul TIKI replied to Mark Ling's topic in Blacksmithing, General Discussion

interesting door design. I like it. I conducted an interesting experiment today. I used feed corn as forge fuel along with my normal charcoal. TL:DR It works, but is finicky A while back, I came across a thread suggesting using corn as a fuel and how it would behave. It occurred to me that I might combine it with charcoal to extend how long it lasts and to increase the amount of heat. I have been having troubles with managing the fire in my forge, probably due to inexperience. In addition, the charcoal I have been getting has been coming in very large chunks. I have to break it up into smaller pieces, but it often shatters to powder, or give me a chip and a slightly smaller but still way too a large chunk. Today, I didn't spend as much time breaking the lumps and then mixed in an equal volume of corn. I got the fire going as normal and then added the mix some way back from the fire to let it 'coke up'. As the fire got hotter, I pulled the mix on top of the fireball. I got some sweet smelling smoke, but not an increase in heat. I increased the airflow and suddenly it got a lot hotter than just charcoal, but it didn't last too long. A bit more tweeking and I got it to where I wanted. I had to add fuel more often, but less of it was charcoal. I had to poke at it more often to break down the clots of whatever the corn breaks down to under heat. The biggest problem with corn was the fire fleas! It was fairly windy today, but every time I moved the fuel or added more I would get a cloud of sparks. I would not use it inside a closed shop unless you are using a high voulume, well designed hood. I'm still re-thinking the shape of my firepot. It's too deep, I think. Fortunately, it costs nothing to shift some bricks and sand to change it around. -

What did you do in the shop today?

Paul TIKI replied to Mark Ling's topic in Blacksmithing, General Discussion

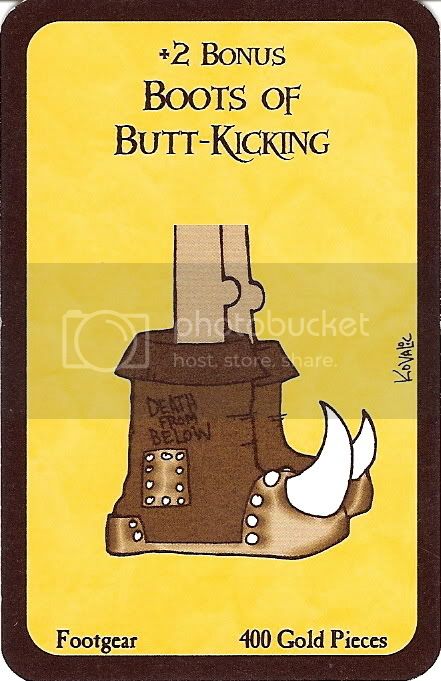

You are pretty close. There is a wonderful card game called "Munchkin" by Steve Jackson Games. It pokes fun at D&D tropes and I heartily recommend it for anyone who has ever played a role playing game and has a sense of humor. The tag line for the game is "Kill the Monster, Steal the Treasure, Stab your Buddy". There is actually a card in the game called "Boots of Butt Kicking" which is +2 Footwear. It goes great with Spiky Elbows, Spiky knees, and the Badass Bandana. There is even a card "Kneepads of Allure" -

I suppose if I build a retort I could route the smoke through a chamber and do a brisket or some pork shoulders and just share with the neighbors

-

That's a nice score there.

-

I found the coal on TSC's website, but not available near me. Anthracite was indeed a bit over 7 bucks per bag, but there was no option for ship to store and no way to ship directly to me. I guess I need to actually go inside and ask, then come home and build a coal forge Or I could just focus on working the charcoal and getting it right.

-

Oddball question, but why is coke so much more expensive than coal? I can't even seem to find either near me. Since I forge in a residential area I figure coke would be a better option than coal, but it seems like it would be very expensive to run my forge at 50 to 60 buck a bag from centaur forge. How long does coal or coke last vs. Charcoal. If I want the heat, I seem to go through fuel pretty fast with charcoal. Of course, If I can build a retort to make my own charcoal it becomes a bit more moot...

-

What did you do in the shop today?

Paul TIKI replied to Mark Ling's topic in Blacksmithing, General Discussion

You forgot "your crazy ex in the bar with too many empty glasses in front of them" Thomas, ready for some impromptu augery? -

What did you do in the shop today?

Paul TIKI replied to Mark Ling's topic in Blacksmithing, General Discussion

I would say a spear is much faster to reload plus it's got great intimidation factor. -

What did you do in the shop today?

Paul TIKI replied to Mark Ling's topic in Blacksmithing, General Discussion

I don't wear a glove on the hammer hand but I do on the other, Mainly because the tongs I have kind of suck. Since I have been using longer stock, a gloved hand has been adequate. I have read about whether a glove is a help or a hinderance or just plain dangerous, but I seem to be in bit of a pickle. without a glove even the longer stock heats too much to be handled after a while. Without tongs, I can't do too anything with smaller stock, and my vice grips and channel pliers don't hold things very well either. It could just be I don't have the experience to make them work. Any thoughts? Or should I move tong build to the top of the queue, so to speak? Also, any thought on those grippy gloves that are basically fabric with a rubberized palm and fingers for holding a hammer -

Welcome aboard. I heartily second pnut's thought's on getting started on the cheap. It's pretty much what I did. The thought of spending a couple hundred on a propane forge plus a bunch of money on an anvil and then the hammers and tongs stopped me from getting started for a long time. Then I found this site and discovered there was no reason not to get started and that it doesn't have to cost a lot to get going. The only thing I have shelled out cash for has been the lump charcoal. Everything else so far has come from stuff I had just lying around the house, so to speak. I have a JABOD side blast forge made from an old junked propane grill so I can close it up when done working and it protects it from the rain. The air supply is a bathroom exhaust fan. The anvil is an old slab of pig iron my dad lugged around for years and I got it when he passed (pig iron is what he called it, it's more likely wrought iron). I started with a ball peen hammer and then my son let be use a cross peen from harbor freight. Channel locks and vice grips that you may already have work ok for beginning tongs. Since I got going last fall I have expended about $50 from a Harbor freight gift card to buy a couple of hammers and an angle grinder (which I have other uses for), but really, not a lot of money spent. So I was able to start on a shoestring, and if I gave it up (not gonna unless health or other issues make me) I wouldn't have a bunch of expensive stuff gathering dust. For the future, I'm thinking about using plans to build a propane forge, but that will be after I build up some some sort of shop shelter. Hopefully I'll have that together by the time my own grandson is old enough to take an interest. As for your anvil I think the other, more experienced smiths, could offer an opinion or ideas. From what I have seen in the anvil threads it may just be a matter of not beating on that broken part of the anvil. I wouldn't know myself, but they might.

-

I probably have the same set. Something like 12 bucks at hobby lobby while the wife was spending a bunch more on oil paints and canvases. I think mine came with a book, or at least I bought a book at the same time.

-

I should dig out my Sumi e set in prep for the spring rains. I got it years ago but never got around to using it. I have paper and felt even. I love the look of the Calligraphy and would like to learn more.

-

What did you do in the shop today?

Paul TIKI replied to Mark Ling's topic in Blacksmithing, General Discussion

Things went much better at the forge yesterday. I seem to have the fire more or less in hand. I'm getting much more heat, using a touch more fuel than I want, but I could just be whingeing a bit because I'm buying charcoal and the price went up a bit. Haven't had time to build a retort to make the stuff yet. Next trip into town I'm going to try to remember to buy some corn to try out some blended fuel with the charcoal, or even just pure corn. As for actually hammering on steel...Thank you Frosty and Thomas! Much less fatigued, hit the steel more accurately, and moved the metal better. I kept my elbows in, so no need to come down here and sneak one into the ribcage! I'm not as sore, either. I am also thinking I have been getting over ambitious with the stock I'm using to attempt to make stuff. Every time something came out like I wanted, I was using a 12" by 3/8" nail/spike. I've used up my supply of those and had been using heavier stock (and failing with it), so I'm going to get more of those nails, not galvanized of course. Use those as I practice and improve and graduate to larger stock over time. -

Man, I am Jealous! I've had smaller apartments. Nice shop. I agree with frosty though. Way too clean

-

What did you do in the shop today?

Paul TIKI replied to Mark Ling's topic in Blacksmithing, General Discussion

I Studied a softer style myself , Wing Chun, though my buddy and sparring partner studied a hard style, Kenpo, and western boxing. With mine, the point of a block was just to deflect from your centerline and your counterstrike should be happening simultaneously. deflect the punch while putting a kick to the knee. Step in to the incoming kick and slap off balance, slip a punch to to the side and begin a series of close in chain punches. You knew you were going to get hit, but with small movements you could rob the shot of a lot of power. Then you hit them with a series of fast blows -

What did you do in the shop today?

Paul TIKI replied to Mark Ling's topic in Blacksmithing, General Discussion

We always sparred with foot and hand pads and mouth guards. If we went into western style boxing, we put on the heavier boxing gloves. Doesn't seen like it should, but those things get really heavy after a couple of rounds. It has been decades since I made any effort to do any martial arts. Time, Kids, and life just got in the way. I have been contemplating trying Tai Chi as I get older. Ten years or so ago I was at the park with the kids. I watched this Lady running about chasing after a 3 year old and just she was exceptionally graceful. She sat down and told me it was her Great Grand child. She didn't look much older than mid to late 40's. She was 75, and she moved better than someone in their mid 20s. She grinned at my surprise and told me that she had practiced Tai Chi since she was a little girl in Singapore. I have tried it a few times and it's a heckuva workout but not so painful on the joints. Also, much less chance of a shin to the face. -

What did you do in the shop today?

Paul TIKI replied to Mark Ling's topic in Blacksmithing, General Discussion

I remember learning to keep my hands up. Paul, your guard is slipping Where? *BAM* Oh, OK. Nothing like a right cross to the jaw to make the point. -

What did you do in the shop today?

Paul TIKI replied to Mark Ling's topic in Blacksmithing, General Discussion

Well, I'm not using tongs at the moment. I have been using some longer chunks of rebar and some long 12 inch nails as stock at the moment. By the end of the day I was deciding that I need to stop with leaves for a little while and just focus on getting some nice tapers and just generally drawing the metal out since it was the point where the leaf ends and the stem begins that was causing such a problem. I was trying to do the SORS method, but with the fire control problem and other stuff.... My one set of tongs is just an old pair that my son brought home and they really don't hold the metal still. I have some material to make those really easy twist type, but that's a project for a later date. Thanks for the hint about hammer control guys. That's one thing I'm sure I was not doing. I guess it's a little like keeping your elbows in when boxing. A couple of good shots to the ribs broke me of that habit really fast way back when. -

What did you do in the shop today?

Paul TIKI replied to Mark Ling's topic in Blacksmithing, General Discussion

Had a very frustrating time with the Forge yesterday. I decided to try something new with the air supply. using a standard brick as the basis I thought I would try a firepot 1 1/2 bricks long with a tuye on either end so I could increase the volume of the fireball. I was losing a lot of air, so I spent a lot of time chasing down gaps and leaks. I got fed up, yanked the 2 new pipes and flexible hose arrangement and replaced it with one larger diameter pipe. The new pipe is the same size as my redneck engineered fan nozzle (Bathroom exhaust fan plus a wide mouth sports drink bottle held together with duct tape). Air control now is the simple expedient of changing the alignment of the nozzle to the pipe. That solved the air and thus the heat problem. So I started working on another leaf. Basics, you know. I found that I was having a hard time hitting the piece accurately with the hammer. Then, just as I got the leaf shaped, one errant blow snapped it off at the stem. Started another and was having troubles getting it to draw out. Then I burned the end of it because the dog wanted attention. All in all, I'm thinking I need a lot more practice. Since I just started last fall, I don't think I really acquired the muscle memory to be truly consistent, and then an enforced couple of months not really doing much because of the weather just left me with a frustrating day. Oh well. With the spring I'll be able to get out there more often. -

What did you do in the shop today?

Paul TIKI replied to Mark Ling's topic in Blacksmithing, General Discussion

That's Fantastic BillyBones! Congratulations! -

I this particular case the dongle was a good thing. It's a simple SATA to USB. Just plug the drive to one end and the usb end to a port on the machine. There was a license key to some software that was supposed to help you migrate your windows over to the new SSD before you install the drive. Since I'm running Linux that wasn't an issue, but since the dongle is generic... I got the drive swapped, then used the dongle to rescue what data I needed from the bad drive. Nothing critical was lost. The actual swap was tedious because HP engineers don't like people who take an interest in the guts of their machines (outside of marketing material, that is) Now all I need is a good 2.5 inch SATA drive to use as a portable backup drive. Probably partitioned leaving 100 gig or so for a new OS to make it almost hot-swappable. I have a few other machines that could possibly fall victim... The end result is I now have a system where boot time is a matter of seconds. POST takes longer than the OS load. Peppermint Linux is FAST!

-

Well, the hard drive on my laptop packed it in. It developed a growing number of bad sectors and kept taking out the boot sector I think. So with the help of puppy linux running off of a USB key I was able to recover the critical stuff Yesterday, my new 500 Gb Solid State drive arrived! Once installed, and with a fresh Peppermint Linux install on it the old laptop is now amazingly fast. Peppermint Linux is quickly becoming my favorite. It's pretty stripped down but has GUI utilities for most things making reliance on the command line a little less. The new SSD also came with a dongle and software to turn a SATA hard drive into a USB connected external drive.