-

Posts

229 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by M.G.

-

Frosty, I have searched for steel suppliers Locally. But I was inquiring about decent scrap (freebies) stock to work from, as I have been out of work for the last 2.5 months and funding is getting low. And reclaimed and recycled material at low overhead seems like a good place to start Also most of the suppliers are not allowing customers in their yard/warehouse at this time. What is this you speak of. FAB shops selling "drops"? Just like splitting off part of their bulk order with a friend...?? I'll definitely look into this said "Metal supermarket" thing. BillyBones, I hit up the guys at a local suspension shop, where they gave me access to their scrap bin whenever I want to stop by. Score! Plenty of coil spring in there.

-

Makeshift Anvil questions from a noob

M.G. replied to M.G.'s topic in Anvils, Swage Blocks, and Mandrels

The weight definitely makes it difficult to swap the orientation without a chain hoist or cherry picker, it will sit just like it is. This thing weighs as much if not more than some anvils. My calculations put it at about 230-250lbs. -

A collection of improvised anvils

M.G. replied to Charles R. Stevens's topic in Anvils, Swage Blocks, and Mandrels

Having been a tattooer for the last 17 years. My hand, shoulders and back are already a mess. I definitely have to warm my hands up before a day of work. I'm very familiar with repetitive wear on the body. -

A collection of improvised anvils

M.G. replied to Charles R. Stevens's topic in Anvils, Swage Blocks, and Mandrels

Oh perfect. I was just going to clarify that Glenn. But that was totally my assumption of how it worked. Frosty: Perfect sense has been made and understood. You guys are great! -

A collection of improvised anvils

M.G. replied to Charles R. Stevens's topic in Anvils, Swage Blocks, and Mandrels

Awesome, thanks Glenn, will do. -

Makeshift Anvil questions from a noob

M.G. replied to M.G.'s topic in Anvils, Swage Blocks, and Mandrels

-

Yeah I definitely understand. They are not for everybody.

-

A collection of improvised anvils

M.G. replied to Charles R. Stevens's topic in Anvils, Swage Blocks, and Mandrels

Got a stand made, and got the dang thing on it. Rolled the piece onto a 2x6 laid it down, set my stand upside down on top of the steel. Used a couple ratchet straps to secure it all together. Laid it on its side....Then me and 2 very doubtful friends tipped it upright. And there it sits until I build my forge. Still gonna soften the edge of the striking surface. The striking surface sits perfectly high enough to tickle my knuckle hairs with a fist.... -

I just sourced out an endless supply of free to me, used coil springs. I should be set for materials for a while.

-

A collection of improvised anvils

M.G. replied to Charles R. Stevens's topic in Anvils, Swage Blocks, and Mandrels

Haha, true. We used a tractor bucked to get the 250ish+ lbs of makeshift anvin in to the back of my car when i picked it up. -

A collection of improvised anvils

M.G. replied to Charles R. Stevens's topic in Anvils, Swage Blocks, and Mandrels

That was the thought we had. I like the way you think. -

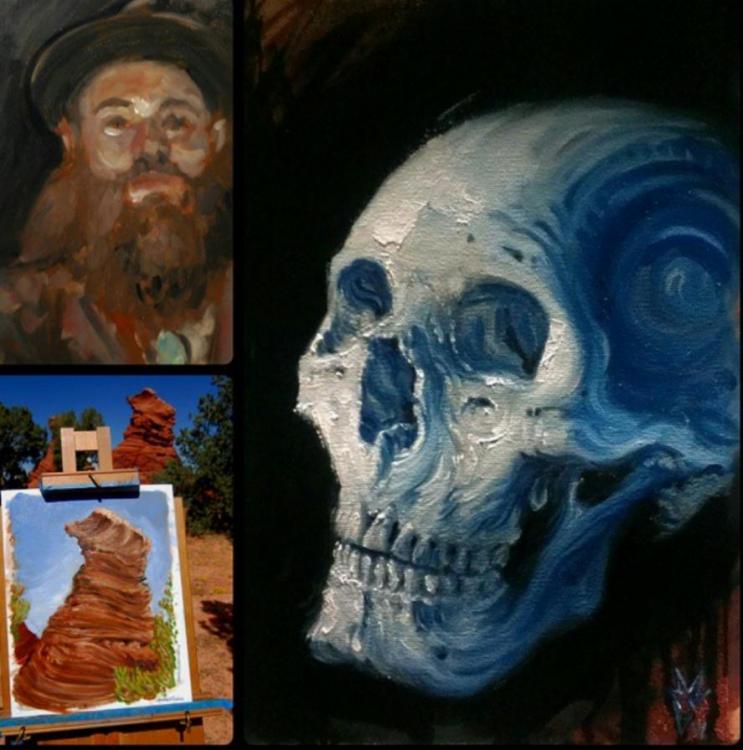

@George N. M. thank you! I'm excited to get to hammering very soon. Thle tattoo work pictured, is work that I have done. If you care to, my Instagram has a plethora of work that I have done in various mediums. Be warned, it is mostly my tattoo work. Being my profession, its what I do the most of.... well until the government shut us down, due to the lockdown regulations. Any way, my Instagram handle is @alteregotattoo I'm happy for anyone to take a peek at it.

-

Hey all.. I missed this section the other day when I registered for the forum. So I figured I should stop in and introduce myself. My name is Matthew, I live in the Pacific NW of the USA. You can usually find me somewhere between the mountains and the sea. Closer to Portland Oregon these days. I am a tattooer by trade, but making things with my hands has always been my passion. Weather it is fine art functional art or just functional tooling, im into it. Over the years I studied precision manufacturing at trade school for tool and die making, CAD for parts and tooling, CNC programming and machine setup and operation, and QC. I have some, but very limited welding experience. In mig tig and arc. I then shifted my focus more to the visual arts side of things. And sought out an apprenticeship in the tattoo industry. Which I have been deeply committed to as a career for the past 17 years. I spent a few years working in a glass blowing studio, blowing borosilicate glass. Building surfboards has also been a passion of my over the past 5 years. Working g in PU foam, and hollow wooden construction, polyester and epoxy resins for fiberglass and carbonfiber. Which brings us to this point in time, where I find myself deeply intrigued by moving molten metal to create. Over the last couple weeks I have been working to put together the materials and tools I will need to get started. Hopefully in the next week or so I will have all I need to put together a solid fule forge, nothing fancy JABOD. I will be trying to document the process and throw it in the forums for fun. Over the last few days I have made a few threads here. And have gotten some really helpful and reassuring feedback. I really appreciate the input from you guys. And I hope to someday be able to return the favor. And just as a bit more of an introduction I will drop a few photos of some of the projects I have done in the past, not smithing related... I will post a couple oil paintings, and wood burnings, and other artworks as well as a couple of the more industrial art type work.. so I hope the MODs don't crack down on me too hard. Haha.

-

awesome thanks Thomas Powers, gonna head out to the wrecking yard later today to look for some coil springs... In all honesty, I have no idea what kind of tongs I like or need. The last time I did any forge work was probably about 17 years ago. Any suggestions for my first couple sets of tongs would be appreciated. Im sure I will be making many sets of tongs over the years. But for now I'll just try to keep it simple. At this point I am working on building a coal forge, JABOD. Maybe from an old wheelbarrow. But in the meantime i am also trying to sorce a small usable stack of scrap materials to make my tools from. I have a handful of scrap. Including a couple hunks of truck axle and offcut round and square billet of some sort of tool steel from a machine shop, and some industrial plainer blades. I figure I've got some good material to make punches chisels and drifts from the truk axle.

-

I just got a warning from a MOD. Saying this thread is in the wrong section.... any ideas where it should be held? Tongs belong in the tongs section, We already moved it

-

Still new, but I know i will need to make a couple sets of tongs in the near future. Having a hard time finding local vendors of raw materials. Wondering what might be the best options to look for in the scrap piles to make tongs from? Or if there is already a good thread that might point me in the right direction please feel free to point me there. These forums are still a little overwhelming. Thanks in advance.

-

A collection of improvised anvils

M.G. replied to Charles R. Stevens's topic in Anvils, Swage Blocks, and Mandrels

It seems like a lot, but those numbers sound like better math than mine. But really Im not gonna be the one picking it up and putting it on the scale. I'll be lucky to get it on to a stand. Hahah -

A collection of improvised anvils

M.G. replied to Charles R. Stevens's topic in Anvils, Swage Blocks, and Mandrels

Ok so after consideration and moving this hunk of steel out of the back of my car and along the shop floor to its temporary resting place. I have decided this weighs much much more than the 90 or 100lbs the fellow guessed it weighs. And if my math is even close to on track this thing weighs close to 200+lbs its 10.75"dia.x9.75" tall. Here is a pic of the start up pile on what I would consider day 1 of building a smithing space. Thanks to everyone that have welcomed me to the community with some small tidbit of advice, I am sure I will have many more questions in the future. -

Makeshift Anvil questions from a noob

M.G. replied to M.G.'s topic in Anvils, Swage Blocks, and Mandrels

sweet thanks -

Makeshift Anvil questions from a noob

M.G. replied to M.G.'s topic in Anvils, Swage Blocks, and Mandrels

Nope, I don't think I know anyone that has access to that kind of technology. I was under the impression that I could hit it with a grinder and visually analysis the spark pattern coming off the workpiece, to get a general idea of the carbon content. But if there is no need to worry about hardening the work surface to get use from the piece, then I assume it dosnt matter if it is mild steel or high carbon... is this a safe assumption? Thanks a bunch, I appreciate the input. -

A collection of improvised anvils

M.G. replied to Charles R. Stevens's topic in Anvils, Swage Blocks, and Mandrels

Thomas Powers, JHCC, Charles R. Stevens, thanks guys. I'll make a stand and soften the edges. Then get to work! -

A collection of improvised anvils

M.G. replied to Charles R. Stevens's topic in Anvils, Swage Blocks, and Mandrels

Good point. Next step is a stand, soften the edges, build the forge build and start whackin -

A collection of improvised anvils

M.G. replied to Charles R. Stevens's topic in Anvils, Swage Blocks, and Mandrels

Ok I found the right thread for this. Im super new to the craft, so any thoughts or input is appreciated. Here is a 10" round off cut I picked up from a guy clearing out his machine shop. Weighs between 80 and 100 lbs is my guess. Any thoughts on modifications I could do to make this even more useful for smithing? Definitely grind the edge softer. Maybe cut/grind a step?? -

Makeshift Anvil questions from a noob

M.G. replied to M.G.'s topic in Anvils, Swage Blocks, and Mandrels

Excellent! Thanks for the input. I will be softening the edge for sure. And I was considering grinding a slight step in to one side. We will be building a small coal forge next week and start hitting some steel soon! Yeah I quickly realized I have picked up something much more useful than an ASO, the guy I got it from claims its high carbon off cut he got from a machine shop a while back.so I'm pretty certain it is not iron. But when it makes it to the shop, I will give it a spark test.... does anyone have any other methods they like to check scrap? I could and will always do more research, the digging and learning is never ending. But I find it nice to engage with the community, and often there is more unlikely knowlage to gain once you get people talking. Thanks. -

Hey guys, I am very new to the craft, and the forum, so I hope this is an acceptable place for these questions. I just picked up a 10" round off cut of steel, it weighs about 100 lbs. Wanting to use this as a basic anvil shaped object. I figure it has plenty of mass. But what I am wondering is, if I should attempt to heat treat the striking surface somehow?? Or if a non hardened and tempered piece of steel is acceptable to use as an anvil?