-

Posts

152 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Jaegers Forge and Foundry

-

What type of welder do I need

Jaegers Forge and Foundry replied to Jaegers Forge and Foundry's topic in Welding Equipment

Thanks to all of you who responded I'll look around for welding supply shops in my area and see what they have. To Thomas I only plan on welding up billets or small fabrication work. Should I look at flux core or stick? -

What type of welder do I need

Jaegers Forge and Foundry replied to Jaegers Forge and Foundry's topic in Welding Equipment

Do you think something like this would be viable? 130 Amp MIG Wire Feeder Flux Cored Wire Gasless Welder, 115-Volt and 230-Volt IGBT Inverter Welding, 80% Duty Cycle $191.00 -

I've researched for a while now and I'm wondering what type of welding machine do I need? I need one that can weld high carbon steel and preferably MIG welder and my price range is in the $100-$250. And do I need a name brand one? Also what is the power needed to run a welder

-

It followed me home

Jaegers Forge and Foundry replied to Glenn's topic in Blacksmithing, General Discussion

I was bike riding on the side of the highway to a friends house when I found a coil spring it looks new because the paint is still there its about 1/4th of an inch thick so I might just make punches or chisels/carving knives with it. Hopefully the suspension spring wasn't in a deadly car crash or something. My guess is it just fell out of someones truck bed -

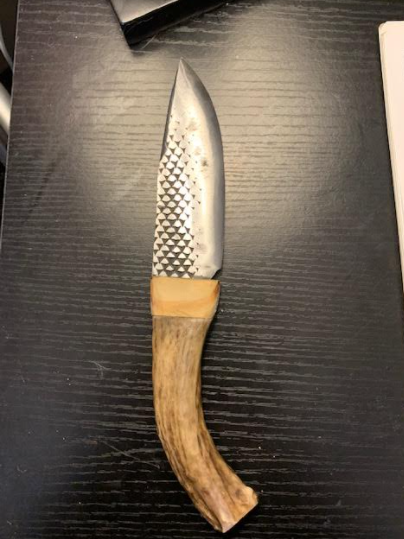

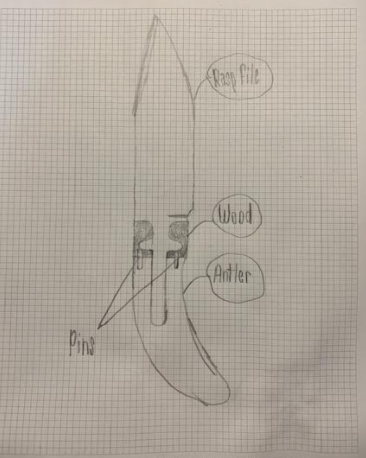

I've been pretty busy with end of semester school stuff, and with ROTC I haven't forged for a week and today I got to the shop from 2:00-6:00 and made a trail riding knife for my mom for Christmas. This was my first one day knife, also one of the best fit ups I've ever done. I used a farriers rasp because she loves horses and an antler that she found while trail riding and gave to me for the handle. If you notice there isn't a pin I didn't use one because i haven't really seen it done before and didn't wanna risk it because it was the only antler I had. However I didn't want epoxy to be the only thing holding it together, so I worked up a design that may exist but I've never seen done before. I put a swell in the tang cut some wood in half and used a chisel to carve a groove that fit around it then put the two halves together so it locked it in place and pinned the wood to the antler. I included my design to show you what I mean.

-

Justin’s Smithing progression. [PIC heavy]

Jaegers Forge and Foundry replied to Justin Topp's topic in Member Projects

I love your posts it's nice to see other teen/young smiths getting into this craft -

Haven't been on this forum in a while but the other day I made my first knife sale I've also gotten better at forging I used to forge the tip and cut in a tang this was the first knife that I forged in the tang and forged in the bevels (which is a huge time saver on the grinder) this knife is also the sharpest knife I made with the most acute edge. And my first forged guard. PS I'd like to mention I did not make the sheath I bought the sheath for a different knife a while back and it didn't fit but it happened to fit for this knife.

-

Ancestors old shop

Jaegers Forge and Foundry replied to Jaegers Forge and Foundry's topic in Everything Else

That's what my grandpa was talking about -

Ancestors old shop

Jaegers Forge and Foundry replied to Jaegers Forge and Foundry's topic in Everything Else

Will do but I have to figure out when still -

My grandpa came over recently and told me about when he was a kid his neighbor (which we found out was a my grandpas uncle) was a blacksmith and made plow blades and other farming equipment. Well my grandpa now is a tax advisor for the blacksmiths adopted son and we might be able to go pick up the anvil that hasn't been used since the 70's and is at least 120 years old and maybe some other forging equipment. Which is cool because I might be able to use my great great uncles anvil. - I don't have pictures

-

My recent projects

Jaegers Forge and Foundry replied to Jaegers Forge and Foundry's topic in Knife Making

Sorry I didn't answer but for the tomahawk I used a axe handle. The push dagger and knife were these long 2 inch by 2 inch square shaped wood beam left from the previous owner of the house. Again sorry for the late replies I haven't been checking this site daily -

Sorry I haven't really posted in a while because of school but here's the projects I've finished in the past week or two

-

Where to get steel

Jaegers Forge and Foundry replied to Jaegers Forge and Foundry's topic in Everything Else

Okay thanks. -

Where to get steel

Jaegers Forge and Foundry replied to Jaegers Forge and Foundry's topic in Everything Else

JHCC Okay thanks I'll look And Thomas is that a website or a shop? -

I was wondering where y'all get your steel because I was looking for 1080 flat stock but the only steel supply shops I find just carry sheet steel or plain steel. Where should I look?

-

Propane efficiency

Jaegers Forge and Foundry replied to Jaegers Forge and Foundry's topic in Gas Forges

Thanks for all the suggestions I'm currently looking online for some -

Propane efficiency

Jaegers Forge and Foundry replied to Jaegers Forge and Foundry's topic in Gas Forges

what should i use as a cheap alternative