Justin Topp

Members-

Posts

856 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Justin Topp

-

Justin’s Smithing progression. [PIC heavy]

Justin Topp replied to Justin Topp's topic in Member Projects

Thanks Pnut. I’m on it now -

Justin’s Smithing progression. [PIC heavy]

Justin Topp replied to Justin Topp's topic in Member Projects

Thanks Will do from now on. Thanks for the tips I’m still learning how the site works beyond just reading haha -

Justin’s Smithing progression. [PIC heavy]

Justin Topp replied to Justin Topp's topic in Member Projects

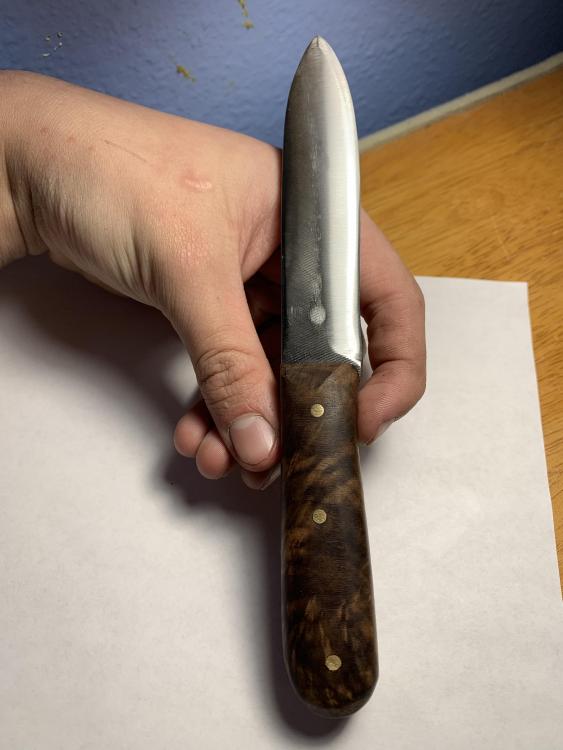

I’ve got some time so here’s more stuff I’ve done. box jaw tongs I made. Wrought iron hook for hanging bird feeders. On the left is a axe slot punch. ( no pic of only it) first axe. Folded and forge welded Viking style 7 oz wrought iron and steel hammer. Leaf textured by iron hammer. Yakut knife from Nicholson file. anvil block/ stump anvil from mild steel and leaf spring. First meat turner first trivet now we are caught up to today. These are a small pair of tongs because often seem to need them for certain tasks first bottle openers used the small tongs to hold these while slitting for the openers. -

Justin’s Smithing progression. [PIC heavy]

Justin Topp replied to Justin Topp's topic in Member Projects

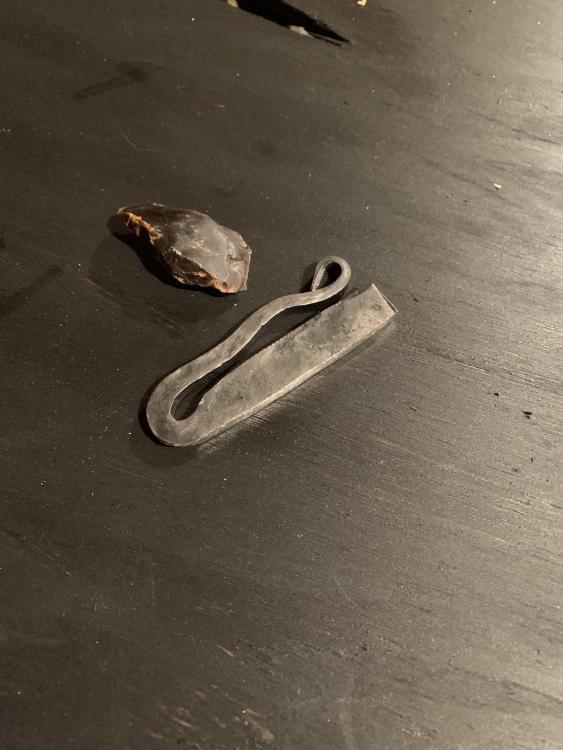

rivets i made. Damascus knife some more damascus I never used first and second hot cut. Dogs head hammer. hammer punch. Round punch and new hammer drift. Handled but it was later switched to hickory once this broke. Fire poker folding knife from cable Damascus. My tong collection mild steel Swedish cross peen with forge welded faces. 3 hour total time knife. Excluding epoxy drying and temper first spoon TongsFailed tongs. 4.75lb rounding hammer. Also my first rounding hammer I’ve made Flint striker. Draw knife second rounding hammer. -

Justin’s Smithing progression. [PIC heavy]

Justin Topp replied to Justin Topp's topic in Member Projects

Thanks! I’ve wanted to do this for a while and finally had the time. I’ve learned on my own because I didn’t know of any classes near me. Now I’ve learned there are some but they are far away for stuff I know already. I learned from YouTube and reading here mainly. -

Justin’s Smithing progression. [PIC heavy]

Justin Topp replied to Justin Topp's topic in Member Projects

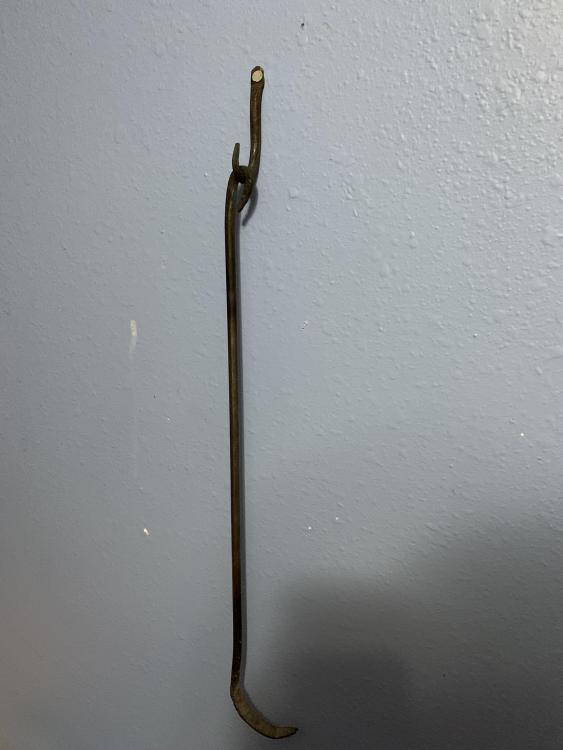

42 photos attached to this post. I soon upgraded to this old buffalo forge rivet forge. and lump charcoal/homemade charcoal instead of the briquettes state of the forge knife from a file with walnut handles. Coal! Still using a hand crank at this time haha. With anthracite. Rr spike center punch. I broke my first fire poker around that time. New rr anvil and state of the forge. First tongs. They were horrible Extendable work rest for long bar stock. Hot cut made for the “Pritchel hole of the anvil. It wasn’t round it was flame cut rough circle so it doesn’t rotate hook for hanging welding mask fire pokers 1st spike knife my first proper tongs a gift from my father first leaf ball peen hammer I found and used a lot. My first Anvil. A 150 lb Henry wright. First project on the new anvil 2nd spike knife 5$ for these plus a ton of other random stuff Center punch and chisel Trace hook. 5/8 round punch I found for about 1$ This beautiful vise day for 2 years in the shear of the house we bought. 70lb Indian chief. cleaned later Shovel I made but don’t really like haha Second leaf 2.75lb cross peen I found Fire tools I made. First hammer. Mild steel soft faced hammer V shaped bending hardy. Rigged a hair dryer to my forge for easier use of coal. 2nd hammer. 2lb straight peen nail header and some nails hammer tongs Rivet kit Thanks everyone. That’s a long post sorry but I’m trying to archive everything. Yes my free time is a huge help to me. I’ve lost some pictures sadly but I’m working on it. I’ll finish and get it up to date later today -

Inspired by Jasent (as you can see in the title) I decided to start a progression post and archive all my work to look back on. I might miss a few things but I’ll try to get most of this. I’ll be adding on as I have time. To start I’m relatively new so I’m going to give some quick information about myself. I am a 15 year old aspiring blacksmith from North Dakota. I’ve always been interested in blacksmithing and recently learned my great great grandfather was a smith. I started in November 2018. These pictures may or may not be in chronological order. I’ll try though. this is my first anvil. I started with a rock making fire pokers but here is my first aso. A chunk of railroad track that weighs 30 lbs and is about 9 inches long. this is my forge I started with. A aluminum terry pan with cat litter and cement blocks. Charcoal briquettes. I had a brick explode but I didn’t know any better at the time. Now I do. Hair dryer for an air supply. this was my first “knife.” A rebar shiv a fire rake I made and have broken and replaced my first hammers. A 3lb cross peen. A 2.5 lb club hammer and a 2 oz ball peen for texture. Horseshoe nail hooks and pendant.

-

Tonight I decided to make some stuff. I’m sure you all know the feeling. Anyhow I made a trivet for my mother and a meat turner. Both are my first attempts at them. The trivet is from about 3’ of 1/4” bar. Three 12” pieces. I welded them on the bottom but if I do another I’ll likely rivet them. The meat turner is forged from about 12” of 3/8” bar. Both have a hot oil finish.

-

Bag bellows are something I’m also looking at. Half the year there is snow so I can use a sled and I’m not into camping like the kind where you hike a few miles into the woods I just drive to the Middle of the forest on our land and Setup a small camp there. So I wouldn’t need to carry that far. But I will find a saw and definitely a fire extinguisher. I always have a extinguisher in the car so that’s already covered. As for a quench tank I was thinking an ammo can

-

I’m not worried about 100% being historically accurate because this is more so meant to be something I can just take camping or to different areas away from my main setup but a historical shop would be sweet

-

I have no need for a fire much bigger than that so I should be set! Thanks everybody

-

Sounds like a mattress pump might be the way to go.

-

A bellows built into a took box would be sweet. Don’t worry I turned a handle for the big file On my lathe i just haven’t stuck it on there yet. Thanks for your concern though!

-

I have that exact pump and one similar. Never even thought of using them

-

Yea this bellows doesn’t suck anything in when I inflate it. Only from the center of the wood. I also planned on maybe a tool box with a smaller built in Japanese style box bellows. And I have a buffalo forge blower that’s 6” and pretty light so I could reasonably take it with if i could find a way to set it up and use that. It would probably be the. Best air supply. For the size. Besides electric that’s is. I’d rather keep it without electricity

-

A check valve is so air only goes out and isn’t sucked back in right? If so than yes. Air only comes out the exit. The intake is in the center of the bellows. And good idea on the vise. I’ll look into a small one of some kind. Any ideas?

-

Starting to assemble a small portable kit I could haul out to the woods or different areas to do some small blacksmithing with. It’s a pretty basic kit but hopefully should do the trick. I’ve bought some of the stuff but the large majority I’ve made myself. Anything obviously wrong/missing

-

Thanks Pnut. The weld went great almost no seam for most of it and it didn’t fall of when I quenched in the water so I’d say it went great

-

Here is a anvil block I made today. About 6 inches of 1.25 inch square stock I forged down to fit my hardy hole than upset down onto itself to form the block. I than forge welded a leaf spring for the face and heat treated. It was originally going to be a mastermyr style Viking anvil but I realized I needed anvil block so now o have one. I suppose I could still take it out drill a hole and hammer it into a log if I wanted. Might try that. Face is around 2” square or a little bigger and it is close to 3 lbs

-

Thanks. This is a left handed variant but it is a really neat design. you betcha. Good luck!

-

Thank you both ! steven I forged it as you would a normal knife but I didn’t have any swages so I just didn’t forge bevels oh this one. If I was gonna make multiple of them I probably would make a bottom swage. To make the fuller I just used a ball peen hammer. This is the shape of the edge. Basically a convex chisel grind with a big fuller. Hope this helps

-

Thank you. I was impressed with the wood. I didn’t expect it to be nearly as nice as it was. Here are close ups

-

Finally finished this Yakut knife I started months ago and forgot about. Forged from a Nicholson file with a Crotch oak handle

-

-

Thought I remembered it haha