Justin Topp

Members-

Posts

856 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Justin Topp

-

Justin’s Smithing progression. [PIC heavy]

Justin Topp replied to Justin Topp's topic in Member Projects

-

Justin’s Smithing progression. [PIC heavy]

Justin Topp replied to Justin Topp's topic in Member Projects

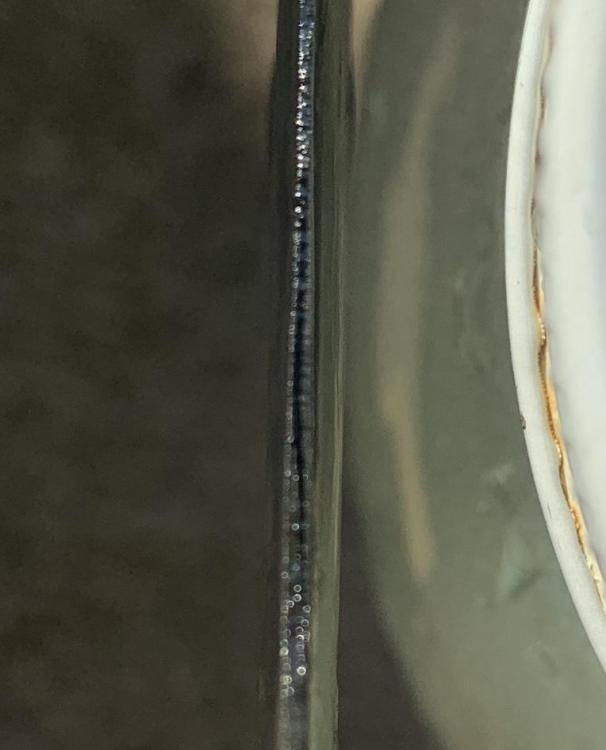

Thomas I can’t exactly just stick a handle on it and use it considering the massive crack in the very center of where the edge would end up. It’s also visible in the Spine so I’m pretty sure a whole layer didn’t weld well. that’s on what would be the cutting edge. -

Justin’s Smithing progression. [PIC heavy]

Justin Topp replied to Justin Topp's topic in Member Projects

I could probably cut a few out From the spine at that size! -

Justin’s Smithing progression. [PIC heavy]

Justin Topp replied to Justin Topp's topic in Member Projects

A wood carving knife might be possible I suppose. It etched weird though. Not sure what the parallel lines are all about. I cleaned it well and polished it -

Justin’s Smithing progression. [PIC heavy]

Justin Topp replied to Justin Topp's topic in Member Projects

I’m Thinking i will break it to test the grain. edit. Never mind. I bent it with a pipe and could barely get it to bend and it sprung back to straight. I than hit with a hammer and proceeded to do nothing to it. I guess it had a good heat treat -

Justin’s Smithing progression. [PIC heavy]

Justin Topp replied to Justin Topp's topic in Member Projects

I’ve already done lots of that! It’s barely mote than 1/16” spine. Pretty sizable delam in the very center of the blade. im not really a bladesmith so I guess I don’t make smaller blades. It’s already Really small. Just a side project so I’m not too bummed it’s also etching weirdly. Unevenly and there’s weird lines -

Justin’s Smithing progression. [PIC heavy]

Justin Topp replied to Justin Topp's topic in Member Projects

-

Justin’s Smithing progression. [PIC heavy]

Justin Topp replied to Justin Topp's topic in Member Projects

I’m going to attempt to make one first Pnut but if I fail I’ll be sure to take you up on the offer! I have some basic letter and number stamps but I want something a little fancier. I might try the engraving and heat thing too! -

Justin’s Smithing progression. [PIC heavy]

Justin Topp replied to Justin Topp's topic in Member Projects

It’s looking to be about 150$-200$ Which is high but if I can’t make one myself I’d be willing to pay it. I saw another for 75$ that seemed promising -

Justin’s Smithing progression. [PIC heavy]

Justin Topp replied to Justin Topp's topic in Member Projects

Thanks everyone. I had planned on attempting to make it myself before sending it off. If I can’t make it nice I’m willing to pay someone to make a nice one for me. I’m thinking buckeye engraving. Can be fairly pricy but they are very High quality and I know several people who vouch for their services. I’m going to use the letter T because of my last name for my stamp and I want something simple. I will likely later change it. If I end up buying I may get a few. My first initial than last name or something -

Justin’s Smithing progression. [PIC heavy]

Justin Topp replied to Justin Topp's topic in Member Projects

Another quick question. For those of you who have touch marks what is a good approximate size(s) for them? I’m looking to stamp tools primarily. I was thinking maybe 1/2” for larger tools and 3/8 for smaller things -

Justin’s Smithing progression. [PIC heavy]

Justin Topp replied to Justin Topp's topic in Member Projects

Sorry for lack of info. I’m looking to make life sized tulips. The stem I’ve got stock for. I’m going to use steel. They will be 3D and will go wherever my mother decides. Likely outdoors. Clear coated to prevent rust. they will get tapered more as I use them and the thinner ones will be for top tools. These are all slab style handles. Flat sides rounded edges -

Justin’s Smithing progression. [PIC heavy]

Justin Topp replied to Justin Topp's topic in Member Projects

What thickness should I use to make flowers? I’m going to forge tulips for my mother so I’m trying to figure out what thickness/gauge of sheet metal To use -

Justin’s Smithing progression. [PIC heavy]

Justin Topp replied to Justin Topp's topic in Member Projects

I don’t have anything better to do hah. I normally would like a bit more swell but I don’t like a huge amount. The hickory I used was a little thin if I was gonna add a swell to the end. I’ll try them out and if I really don’t like them I’ll use them for top tools and make better handles. Top tools are half my reason for making these too. Right now I usually end up sticking a branch or broken rake handle in. I might try the tape trick you mentioned Pnut. Also final measurement of snow was 9” at my house. No snow and 60 degrees to 20 degrees and 9 inches over a few hours. Fun times. I guess spring was an April fools day prank -

Justin’s Smithing progression. [PIC heavy]

Justin Topp replied to Justin Topp's topic in Member Projects

Various reasons mean I can’t go forge for a couple days. Such as online school and 7 inches of snow in 6 hours. It was 60 yesterday and it’s 15 degrees now .... so I’ve decided to stock up on hammer handles. I’m making 25 plain gently tapered hickory handles for hammers. Here are the first two. Slight taper to the eye but not much as I want to leave wood for when I go to hang the hammers. Domed the butts of the handles as well -

Symmetry will can be annoying but it’s important. Thanks. The third hammer I finally figured out where I need to put the fuller haha. Thank you though.

-

Thanks! I like them but I also like uncharred. The char smooths wood so it’s less sanding to do

-

Been a while since I’ve posted hammers here so I figured I’d show what I’ve made. To start off here is a 2.5 lb cross peen on a 16” hickory handle I recently forged. up next is a 1.75 lb rounding hammer on a 14” charred hickory handle. finally a 3.5 lb rounding hammer on a 16” charred hickory handle. I feel I am finally starting to make nice hammers and was curious on what you all think?

-

Awesome! I’d love to find an old rounding hammer for that price

-

I’ve left wrought iron in ferric chloride for a few hours to etch it

-

I’d love to see your take on it when/if you make it

-

I really only needed to use this one size and I can make a new one of these things in like 30 minutes so it’s no big deal. I used 5/8” round I believe. Medium carbon from an old wrench looking thing that had a round handle. I used medium carbon so it wouldn’t deform over time like mild steel might

-

Thanks. I had solid so I figured less hassle so I used it. I thought about making a removable die but I made primarily for hammers and it does the job great for hammers. These two were made using it