Justin Topp

Members-

Posts

856 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Justin Topp

-

Been big into ice fishing lately and had gotten into pike spearing. So I decided to make my own spear. Season closes this week so I won’t get a chance to use it till next winter but I think it should work well.

-

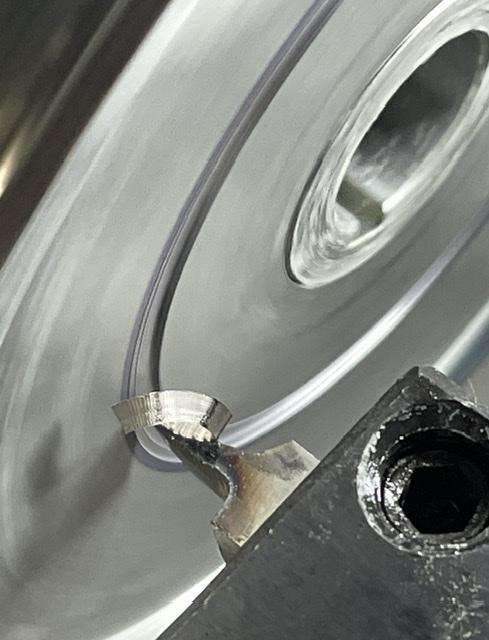

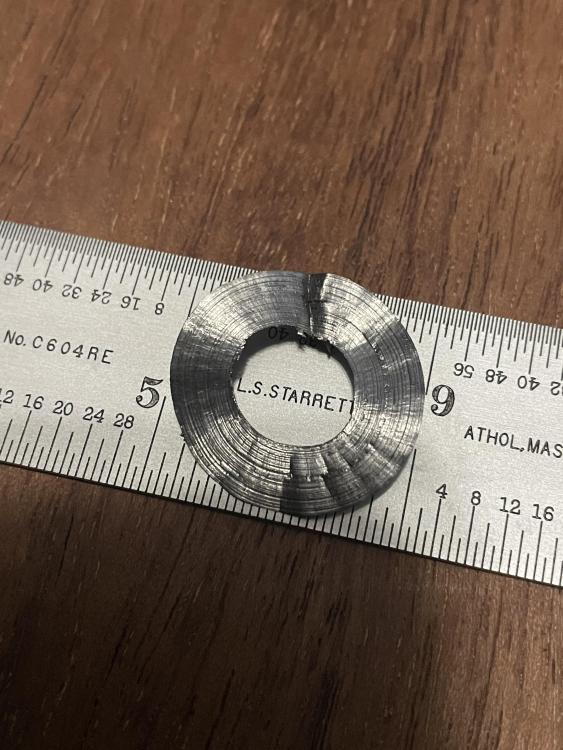

Practicing on the lathe, trying to improve surface finish. I’m using a vertical shear tool for this. I think I’m definitely getting better finishes now but still could use some work. It’s much better in person than it looks on the photos, And feels super smooth. It’s 1018 so not exactly known to be the nicest steel to finish. Got some neat steel wool as a byproduct

-

I would’ve just bought it for slightly more instead of spending a few hours messing around in my garage but where’s the fun in that!

-

I’ve been learning it! Making a few useful parts even! Here’s one thing it was great for, needed a smaller pulley for the Massey 14, for the snow blower attachment. So I used the lathe to take the hub out of a pulley and mark the pulley to drill holes. Worked great. (Gloves were just to pick the metal up since it was about 10°f in my shop at the time. Taken off during operation) I think a 9” SB lathe would be fantastic. This just was available at a better price. I’m happy I got it. They are super useful. I am going to practice some more and maybe buy some insert tooling, though I like using and learning hss. (The lathe is more suited for hss speeds anyways.) Then I’m going make some pistons and cylinders to hopefully make a alpha configuration stirling engine

-

-

Justin’s Smithing progression. [PIC heavy]

Justin Topp replied to Justin Topp's topic in Member Projects

Im thinking I’ll do something similar. I definitely don’t need the 8” for most things but it will be nice for heavier work -

Justin’s Smithing progression. [PIC heavy]

Justin Topp replied to Justin Topp's topic in Member Projects

Im going to mount my 6” leg vise too. Which I’ll probably end up using the most. It’s my favorite vise I’ve used yet. May also mount my 4” somewhere. Not sure yet. So something like the second finalist axe I made is better? Where the handle is very minimally thinned to go into the eye? I’ll take a look at him. Thanks -

Justin’s Smithing progression. [PIC heavy]

Justin Topp replied to Justin Topp's topic in Member Projects

Gave knife making another go. Was looking good but I messed it up. Back to blacksmithing I guess! I am finally getting around to making a stand for my 8” leg vise. The whole setup weighs about 475 lbs. made of some plate, some h beam, and a 27” lathe face plate photos appear to be sideways -

Ordered a quick change tool post and some more hss blanks. Finally I will be able to get making some real projects I’ve also been prepping to make a flat belt pulley so I made this headstock center for the 3 jaw chuck. I’ll just take a light cut before each use to true it up

-

That would be nice! I’m more interested in a Bridgeport manual for now though. Friend has a haas if I really need cnc. Although a mazak would be nice!

-

This is becoming my machine thread. If there’s a better place I’ll start a thread there. But I’ll keep it here for now. With that being said, I found this palmgren vise and cleaned and de rusted it. Hoping to do some testing on it to see if it’s at all square to use on my milling machine. For light not super precise work if nothing else. Jaws are micarta. I May eventually make some steel or aluminum jaws. Not sure yet.

-

That would be fun to watch run!

-

Trust me I’d love a monarch but this southbend is more than enough for my garage for now haha. I bet I could take a 3/8 cut with the southbend. Using the back gears and a reasonable feed. Not nearly as impressive but more than enough for my needs. Once I’m a bit older and out of high school with a bigger shop I’ll look for a better lathe. Parts are either available or easily made which is nice for me as a hobbies. Those big planers are fun to watch!

-

The drill is only 900 rpm so not quite as fun but will be a rush haha

-

Interesting, since it’s a scientific blower would it be used in a lab? Or is that just a brand name/thing.

-

That’s true! I’ll be very careful

-

I will be! It’s a good quality bit that I’ll be sure to keep very sharp. The drill is 670 watts so it’s no joke. Luckily it’s pretty slow and has good handles. I’ll definitely be careful. I’m drilling with 5/32” than 1/4”. Than the 5/8” drill. Seems to be a good order to prevent the drill from catching.

-

Got some 2” round ready to turn the pulley. I’ll bore it out for whatever motors shaft I get. Than turn between centers and put a 1-1.5 degree crown on it. That’s a number I’ve been told will work well.

-

Yup. Lots of accessories! its a pre existing table Im modifying. Weighs about 400 pounds as is. I’d like it to be heavier but I made use of what I had available.

-

Decided to drill my table out into a low budget, low accuracy fixture table. Mainly to make clamping work down easier. My table is 5/8 plate and setup to take 99 5/8” holes at a spacing of 3”. Makes me wish I had a mag drill. But you gotta use what you got I guess. layout pilot holes starting to drill 5/8 holes

-

Any photos? I’m a sucker for old cast iron haha.

-

Mine is babbit as well. They are grease caps not oil caps but they are missing the threaded plunger so I’m just using oil. my pulley is flat, they need to be so the flat belt doesn’t slip off if it’s slightly misaligned. Im not sure what the end thing is. Probably something to take up the slack like you say. I have good enough blowers as is but I love old tools so its hard to say no to One like this haha. They also just look cooler and are quieter running than most modern blowers.

-

Recently picked up this champion no 1 blower. Everything turns and moves smooth without play. It was extremely smooth once I added oil. No heavy corrosion anywhere. I’m excited since I’ve been looking for a cast iron, belt driven blower for years now. This one came up and I offered $50 and got it. Only took 6 hours of driving but it was worth it to me! Once I get a motor I will be turning a flat belt pulley for it so i can power it.

-

This lathe is great! Makes that craftsman seem useless haha 0.260” depth of cut on mild steel. 270 rpm with a feed rate of 0.0021” per revolution. 1/4” cuts and I’m not even using the back gears yet! The lathe has also proved extremely useful for creating steel spacers. It’s so nice not having to stack washers anymore. And I can get the same thickness of spacers for different sized bolts. Before when I used washers, the washer for a 1/2” and 1/4” bolt were different thicknesses so it would be hard to get even stacks. I also made a rough fly cutter. Need to work on sharpening cutters and stuff for better surface finishes though