Justin Topp

Members-

Posts

856 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Justin Topp

-

Did you make a YouTube video on those? I swear I remember watching one about a shipment you got.

-

An anvil just went up for sale near me and oh how the anvil envy Has set it. I don’t need it and won’t buy it because I have a 150lb Henry wright but it is a beauty. 490lb peter wright in pretty darn good shape for 3000$

-

Favorite handle making and wedging method?

Justin Topp replied to Justin Topp's topic in Hand Hammers

I’ve only seen a few natural types of cactus When I went to the western side of the state and they are just these Little tiny things. Other than those and plants from the store cactus won’t grow up here because it’s too cold for them. occasionally I’ll see fresh prickly pears at the store and buy a few but they go bad quickly i assume because they grow so far and have to be transported all the way up here -

Favorite handle making and wedging method?

Justin Topp replied to Justin Topp's topic in Hand Hammers

Prickly pears are awesome. Too bad they don’t grow around here ... -

Thank you Jon. These style of hammer also appealed to me so I figured I’d just go and try it. I’m slightly jealous of your wrought iron collection haha. pnut im not discounting small hammers because my 2 lb moves metal faster than my 4.75 lb but this 7oz isn’t gonna get a ton of use for most things. Haha. It I had it’s purposes though. benona blacksmith you hammer looks great! That’s right about the size of the next one I wanna make

-

Thank you very much ! I use small ones fairly often and wanted to try texturing a leaf with a cross peen but did not have any with a small enough edge so this meets that requirement. My smallest hammer is 2oz ball peen that I mostly use for the hammer texture. This is my second smallest. I’ve got a bunch of old WI horse shoes as previously mentioned in separate threads. I like this style of hammer quite a bit and I think I want to make one around the range of 2-2.5lbs. Preferably 2.25 lb

-

Thank you! I may or may not have been slightly inspired by the mastermyr find haha. It’s not a exact copy but roughly based on the Viking style. Yes the peen also has a little bit of steel forge welded in. I cut that wedge in half because it was too long. But yea

-

-

Favorite handle making and wedging method?

Justin Topp replied to Justin Topp's topic in Hand Hammers

That would make more sense. It has rather poor grain for hammer handles it seems. Rather course -

Favorite handle making and wedging method?

Justin Topp replied to Justin Topp's topic in Hand Hammers

Russian olive works for handles? Good to know it’s all over here and I collected a ton of it. Beautiful stuff too. Thanks. I have a bunch of ash I might use. It hasn’t been killed yet though -

Favorite handle making and wedging method?

Justin Topp replied to Justin Topp's topic in Hand Hammers

I like to sometimes buy old sledge hammers at auctions and use the handles from them if they are damaged at all. Chop the damaged part off and use a draw knife to size the wood -

I spend most of my free time Reading this site when I’m not forging And It’s never short of content. Sometimes there’s so much I can’t find what I was looking at previously haha

-

Thank you! I’m still learning the site as I mostly prowl the tongs and hammers sections haha. Found this area so I figured I’d share. Too bad most of the collection is scattered around haha. I’ve given away the majority of what I made. Some of its in my city. Some of it’s 300 miles away with family or friends and the commissioned one is around 900 miles away but I’d rather give them to people who appreciate them than keep them myself so it appears for me on mobile the twist knife appears really short and far when it’s actually fairly long and skinny. Not sure if it’s just me Or looks odd to others but that picture is a bit distorted to me.

-

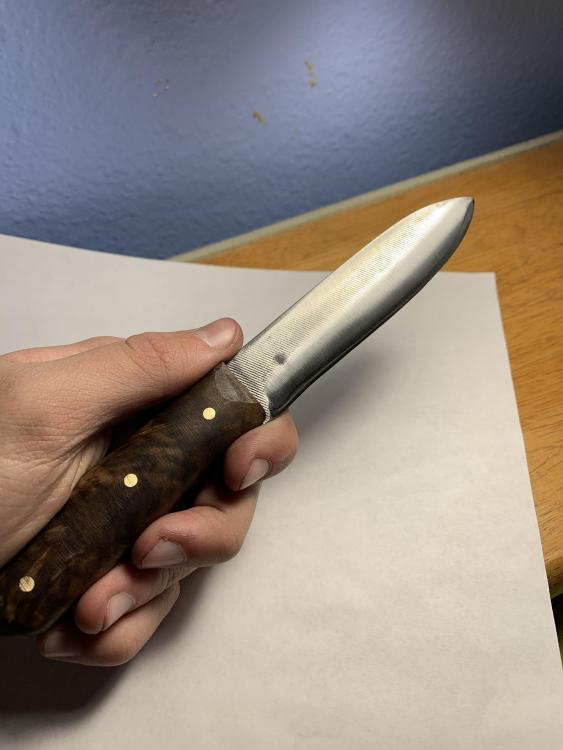

So my love of knives started at a young age and at 12 I decided I wanted to make one. Made my first when I was 14 and over the last year I’ve made. Decided to post some of my favorites I’ve made. Started out wanting to make knives but I got bored and kinda gave it up haha. I’ll keep this short and if you want more info on any of the knives just ask. To start there is my first folding knife made from padouk with my first cable Damascus. A brass stop pin and stainless steel pivot screws and barrel with 0.005” phosphorus bronze washers. Next is the first knife I was really proud of. A hunting knife made from a old Nicholson file with walnut and brass pins. Next is my stock removal knife that I hated and won’t do stock removal again. 420 stainless Santoku. Bought the stainless ore heat treated online and I’m not 100% sure how hard it was but it wasn’t super hard or super soft. It holds an edge well so good enough for me. The handle is blood wood and ziricote. The next is a 5160 cleaver Santoku made for my first and only commissioned piece. Walnut handle with steel pins. Next is a twist pattern Damascus knife with a handle made of some old pallet wood. Looks like a burl. It has brass pins. Finally is my first Damascus knife. A small little puukko sorta shaped knife that was a tad funky but comfy and one of the sharpest knives I’ve used haha. Handle is purple heart and ziricote with copper. These are my favorites of my around 15 I’ve Made. Whew that was longer than expected. Oops.

-

Favorite handle making and wedging method?

Justin Topp replied to Justin Topp's topic in Hand Hammers

i would make my own but I’m not a fan of slab handles to honest. I’m probably gonna order a bunch of ash blanks from thrane axe and saw they are cheap and good quality from what I’ve seen -

The start very small of a wrought iron and steel faced hammer. 8.3 oz as of now. Wagon wheel wrought iron made into a new hammer billet that. I cut it and forge welded it together to get the current shape. It’s amazing how it moves and the self fluxing is awesome. I than took some 1045 stock and cut some hooks into it and hammered it onto the wrought iron. Heated it took the picture and then very lightly fluxed it for the 1045. Took 2 welding heats than a third heat at welding temp to refine the sides and help cleans the seam up. I would say it worked as it looks and sounds like one piece. And when hot the color is even and I no longer see a difference between the iron and steel. Tomorrow I will keep working on it. Will reply with updates as it progresses.

-

Ok thanks I’ll check them out

-

Ah I see. Might not be able to get one then. I’m kinda far away from any of them

-

The few I’ve used have also been from our horses. Except the WI ones I bought those at an auction and I just figured out they are WI after months of having them haha. I don’t really forge many horse shoes to begin with so I’m not that knowledgeable on forging them haha. One day I’ll make some hammers and sell them but for now I’m too busy with school to make and sell hammers

-

Thanks for the replies. I agree it looks nice. Diamond horse shoes are the best shoes for forging I’ve used. Then again I’ve only Ever used Two types. Diamond brand and some really old wrought iron horse shoes haha. My rounding hammer I bought is from a maker called whiskey turtle forge. It’s a beautiful 2.5 lb rounding hammer. The other two I have were made by me. Dunno if order is right but there is the 4.75 lb i made with the charred handle than the 2.25 lb I forged and finally the rounding hammer I paid for. It is the one with the goodies I was sent because I was chatting with him and he actually gave me all the advise and tips on how to make my first hammers. Also the WI horse shoe. I’ve also never seen any used rounding hammers but I’m sure they are around. I forge mainly with the 2.2lb straight peen I made myself. But I just like hammers so much and always want more haha. ive never really tried a true temper hammer before. I’d be interested in getting a larger cross peen. Where are they sold? Or are they antiques

-

Fair point Thomas. But I already do make them haha. I just saw these and liked them. I spent 118$ on a rounding hammer from a fellow smith and I’ve gotten my money’s worth and I love the hammer. I would never buy one for that much from a store but still. I’ve also made my own rounding hammers that I like and use. I just tend to hoard hammers. My favorite is a straight peen I made. On your comment about forging with your arm not your ego I think I fit that pretty well. I have hammers ranging from 2 oz to 9 lb and I’m most comfortable with a hammer in right around 2 lbs. with a 16 inch handle. That’s something that drew me to the 80$ hammer. It’s smaller at 1.8 lbs so I like that and it has a 16” handle so another thing I like. Thanks. pnut- thanks and that’s definitely true. I might end up just ordering some 1045 and making my own of that size

-

Anyone got any experience with either of these hammers? Found at a local runnings. The 1.8lb has a really comfortable handle. They are pretty good priced and if they are good Quality I wouldn’t mind having them. I also like the long handles on them. They are also on the lighter size so that’s handy as I already have a 2.25lb a 2.5lb and a 4.75 lb. I don’t need any more hammers but I like hammers .....

-

I switched to boots when my sneaker caught fire... oops. My boots are also more comfortable to work in and my summer boots are steel toed so even better

-

I’ve almost got an igloo haha. It shrunk a lot from a 40 degree day we had. Dunno why it got so warm but it was nice. Made an axe I posted in the axe section. I have insulated leather boots rated -40 so I’m all good On the cold feet aspect. I typically don’t forge when it’s bellow zero unless it’s been a few days and I’m desperate. when it snows here I have to wait 5-6 months for it all to vanish haha

-

Made my first axe today.

Justin Topp replied to Justin Topp's topic in Axes, Hatchets, Hawks, Choppers, etc

Yup planning to use it for processing wood this winter. And camping to see performance