Kako95

Members-

Posts

18 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Madeira Island, Portugal

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

I currently have a firebrick forge but I as looking to upgrade as the temps aren't really consistent nor, I feel like, high enough. I found this in amazon, hopefully that's it? West System 406 Collodial Silica 275g https://www.amazon.co.uk/dp/B004QXLKT2/ref=cm_sw_r_cp_apa_i_JCZKDbNMF5AAN Thank you for your experienced inputs! 20190228_162212.mp4

- 5 replies

-

- refractory

- lining

-

(and 2 more)

Tagged with:

-

Hi everyone! Please, I know, before you bash me, this has been asked hundreds of times. The problem I have is that I have ABSOLUTELY no access to any of the 2000C° plus refractory linings. I live on a small island in Portugal, there are no blacksmith, no forges, so no forge related stores. And due to EU regulations, most refractories contain chemicals not really suitable for exportation/importation so any outside shops I find, don't ship them here. I managed to buy a decent amount of ceramic blanket, but I'll be getting my cancer through smoking, so I need to coat it. So I was thinking if I could basically make a thick steel box, stuff as much blanket as possible in there and make another square box thing to use as the inside walls of the forge. I wonder if the heat would cause so much warpage that the steel would just unweld itself, also thought about expanding gases inside the insulation so I would drill tiny hole just to vent the extra pressure so it wouldn't blow up on me. Any help, someone who could send me some castable refractory, is greatly appreciated. TL;DR : Can I use steel plates as my forge lining?

- 5 replies

-

- refractory

- lining

-

(and 2 more)

Tagged with:

-

Made the radius on my anvil today, didn't want to overdo it without getting an opinion, easier to redo that to undo. What do you think? Said by side comparison. Also got my first touch mark of many to come today funny how it's so hot it doesn't even hurt, everything just dies. Oh well, tools of the trade I guess.

-

Oh, on the way home is was trying to figure out how to keep that little edge from happening, now I understand. Thing is, my anvil edges are in mint condition so I'll have to figure something out hehe Thank you so much frosty, your help has been invaluable, I wouldn't have managed all of that on my own, specially with no one to help around these parts.

-

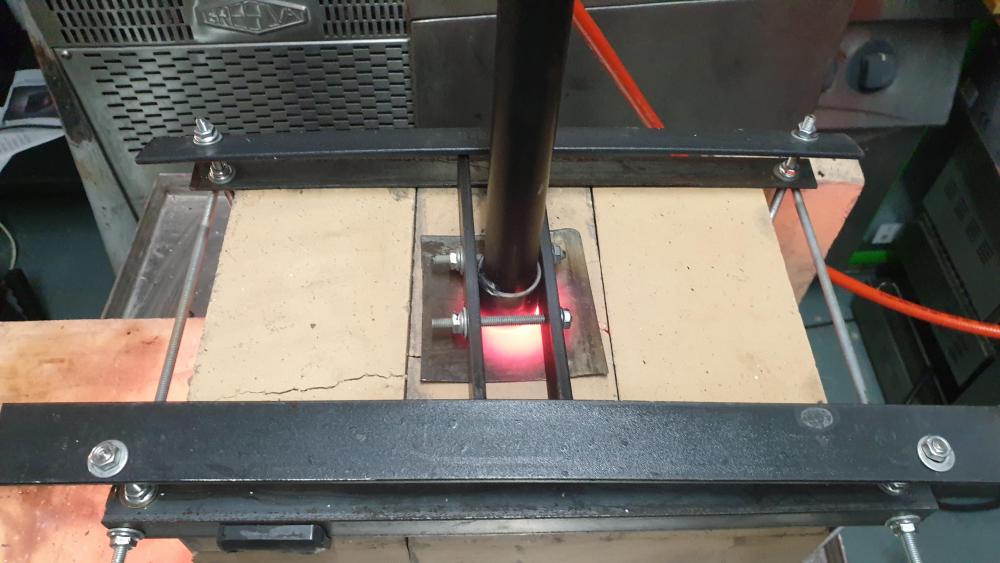

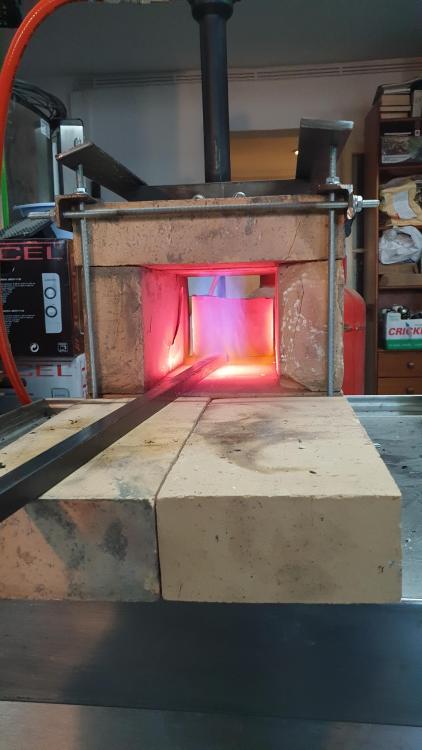

That's what I was thinking after I looked at the picture, the hole is definitely huge and in messing with th whole forge. I'll get to drilling tomorrow, as that needs to be resolved asap I noticed the flame was rich as well after the picture and did some fiddling with the tuning again. Once the forge was hot i wasn't seeing any orange flames. What's happening now is that the stainless plate is gating red hot, again, due to the huge hole, must fix that. I noticed that today there was a bit more scaling, like what in used to seeing in videos, so maybe I'm starting to get to the sweet spot. We'll see once I redo the hole. Tried my hand again at a leaf, still somethings that I don't like but hey, for a learner I don't think its too bad. (wire brushed it afterwards to look shinier) Also, still can't get the little roll when separating from the bar, it keeps 'breaking' on me

-

-

There's a couple of errand hammer blows, which showed me I need better control, a couple of delaminations which I noticed was from when I made the shoulders, not hitting on the same spot and I couldn't get the main vein in, again, better control. Also, couldn't get the hoop done, from not tapering enough The scales is probably from my excitement to see my work that I quenched in water because I didn't really notice any scales forming when forging, and I did brush it from time to time. I know, never quench in water, but I figured this was just a mild steel practice piece so I didn't bother Exactly, that's why I said it was a great learning experience! It makes me really happy and excited to hear encouragement from experienced smiths

-

You're absolutely right, but I wanted to show how the flame was doing and thought 'since I'm here and filming, might as well show the rest.' will take pictures tomorrow. The burner isn't as far back as you recommended, need to so some changes to the rig I setup to hold the burner, but I was just too excited to do that today lol The hole in the brick is 55mm wide, which is huge, I know, but I was planning on doing something different before I bought this burner, gonna drill another brick with the appropriate size, just not looking forward to almost an hour of drilling to get through that thick SOB. To counter that for now, I just drilled a hole on a sheet of stainless still that rests over the hole and is kinda snug to the burner. Obviously not air tight so some air does pass through. I did notice that the flare would not get red where it protrudes the brick so I see what you mean when you say to pull it back. Again, going to take detailed pictures tomorrow. Yes I did, I managed to get the steel to quenching temperature (magnet check) and tried my hand at one of those leaf Keychain things that alec steele reccomends for practice. Obviously didn't come out as expected but it was a huge and great learning experience. Not too shabby considering it's my first time swinging at steel. Thank you all for the great help, especially you Frosty, I've noticed you're a dear member of this community.

-

Made the changes, this is what I have, what do you think? Tip still seems to get red hot 20190301_151850.mp4

-

I do have some understanding of the science behind it, as I've done my research to build a burner of my own. Couldn't manage mostly due to the lack of the right materials. I like doing my homework before doing anything to make sure I have the best chances of success, I obviously lack the experience tho. Thanks a lot for the help, I'll try all of the above later today and give you some feedback, I'm confident it'll work. Also, as I said, the forge I have I think will suffice for now, as I gain more experience and love for the trade I'll obviously upgrade. Just didn't want to spend too too much on entry level. Again, Thanks a lot and fingers crossed

-

Yeah, it's the measurement used o their gauge. But I can see how that makes some sense as my forge is on the smaller size. I guess I got a bit scared of going lower pressure as there were huge orange flames shooting out, guess I panicked a bit and didn't adjust my choke. Again, more testing needed, just wanted to see if there would be a merciful God who would enlighten me.

-

As always, quick and helpful community, honestly one of the best forums I've been part of. Anyway, at the time of recording I was using 0.1 mpa, which I already thought it was low, as I've seen people being successful being around 0.15mpa I can't really remember but I believe that when I lowered the pressure I would get orange flames shooting out the entrance and the choke would not prevent that. My assumption was that there wasn't enough venturi effect to draw air in. I'll do more testing tomorrow. Also, do you think I'll have any problems with the flare getting red hot? I'd think that that would just cause the flame to burn earlier, don't know if it causes any major long term problems. Do you recommend closing the back? I'm actually impressed with the insulation of the bricks, I could get a 1cm square bar into forging temperature in less than 4 minutes, I don't think they'll be a problem, for now at least. Could also be because, as you said, I was running too rich.

-

Hey everyone! Newcomer to blacksmithin, just got done building up my forge. Just some firebricks stacked and a Devil's Forge propane burner. (see video attached) One thing that i noticed is that it seems that my burner tip seems to get Red Hot, kinda looks like it's burning too early in the flare and im not sure about the flame noise (Never seen a proper forge in my life, no one forges in the island where i live) I've spent about an hour fiddling with different pressures and air intakes, to no avail (maybe the tip was so hot that it was messing with the tuning) I was wondering what tips do you have and if you think the tip getting hot and the noise. is normal Thank you video-1551376922.mp4

-

Help needed to secure anvil

Kako95 replied to Kako95's topic in Stands for Anvils, Swage Blocks, etc

Thanks, will read. I'm guessing 15 to 20kg,haven't got a scale on hand -

Help needed to secure anvil

Kako95 replied to Kako95's topic in Stands for Anvils, Swage Blocks, etc

Quick update on the restoration. Still got the nooks and crannies to take care of but coming along nicely. Edges are in mint condition. The brand is Ferfor, maybe someone know anything about it? Also, Thanks a lot for all the tips, luckily I have a lot of wood at my disposal (live in Madeira Island, 60%is trees) so I'll have a few trial and errors and update you when I can.