-

Posts

40 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Spokane, WA

-

Interests

Blacksmithing, hammock camping, hiking, fishing, archery, knives and fire!!

Recent Profile Visitors

916 profile views

-

I’ll try to upload pictures of my tongs. I only have tongs I made. Never tried a real set yet.

-

Just an update on my forge build. I made a mount for my burner and played with the air gap from the burner flush with the forge so no air could come in around it and pulled it away up to 2 inches to let in max air mixture. I also played with making different nozzles. I found that a 1/2 to 3/4” gam on MY SETUP works best. I have forgewelded several times already so its hotter than I need it to be. 1 standard BBQ tank Lamar me 12+ hours of forge time making Flint strikers. I have the materials to insulate my forge and will update here when I start the process. If you haven’t seen my forge search MICRINI forge to seethe build. This place has been a wealth of knowledge for me!

-

Sounds good.

-

Just an update on my forge build. I made a mount for my burner and played with the air gap from the burner flush with the forge so no air could come in around it and pulled it away up to 2 inches to let in max air mixture. I also played with making different nozzles. I found that a 1/2 to 3/4” gam on MY SETUP works best. I have forgewelded several times already so its hotter than I need it to be. 1 standard BBQ tank Lamar me 12+ hours of forge time making Flint strikers. I have the materials to insulate my forge and will update here when I start the process. If you haven’t seen my forge search MICRINI forge to seethe build. This place has been a wealth of knowledge for me!

-

That’s pretty interesting. The shell especially. I wonder how hot it it outside the shell?

-

Yes I agree. I won’t use it enough to justify buying a top dollar machine when a harbor freight one will do just fine. I will need it and a tap set to do thebuild. That’s the only thing stopping me.

-

I’m reading about these 3/8” burners and looks like I’ll need a drill press. I’ll be buying one soon.

-

I thank you for encouraging words. I’ll do just that. Okay aroundwith coffee can or muffler firges and small burners!

-

I don’t mind any feedback! Thanks I had the brick 1/4 away from the rear opening. But I also add a lip to keep the rear ending closed a bit more than the front. The flames out the rear and Fron are almost equal in amount. The burner is faced towards the rear but When I angle the burner even more that way flame only comes out the rear. I tried closing the ends withbricks and it seems to hold heat but the way it’s burning now is very hot. I know now what your saying about neutral flame. I can get it to do that when I pul the burner out and leave a gap for air to come in with the flame. But it actually took longer to heat up and when I put anything in the chamber it blowed the flame back out that gap. Likeghechamber is pressurized. Weird. The forge gets hot! I have a 6” square pipe same length as this forge and I think I’ll use it and put this little one in the6” one but first wrap it with Koawool. Maybe that will help it retain some heat? Not that I think it needs it because it gets way hotter than my micro forge!

-

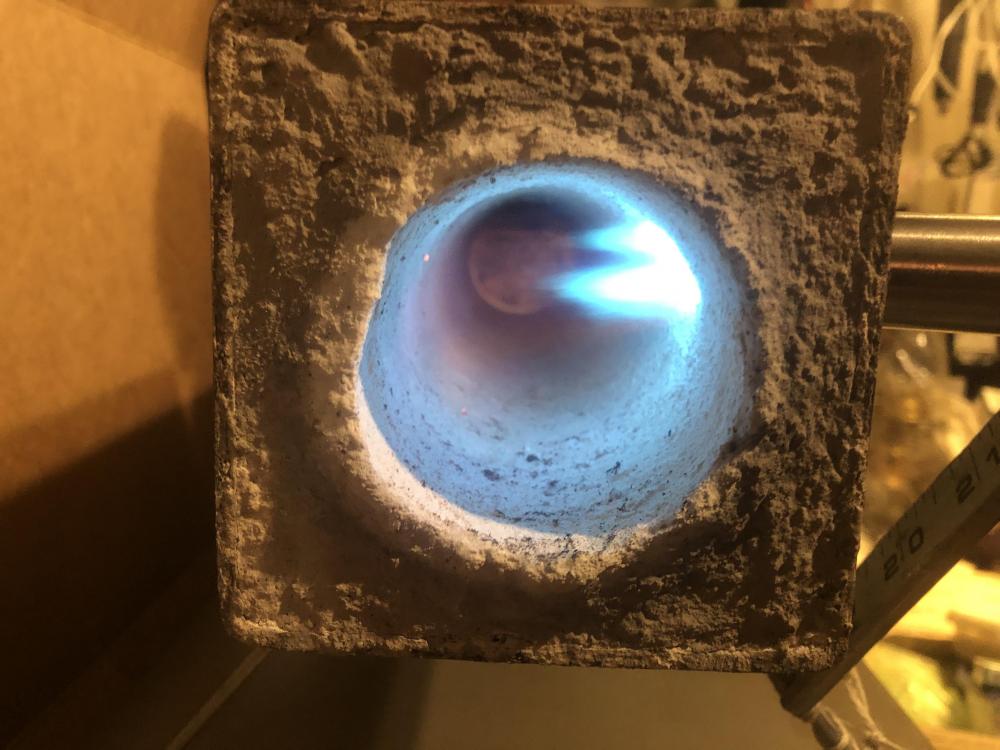

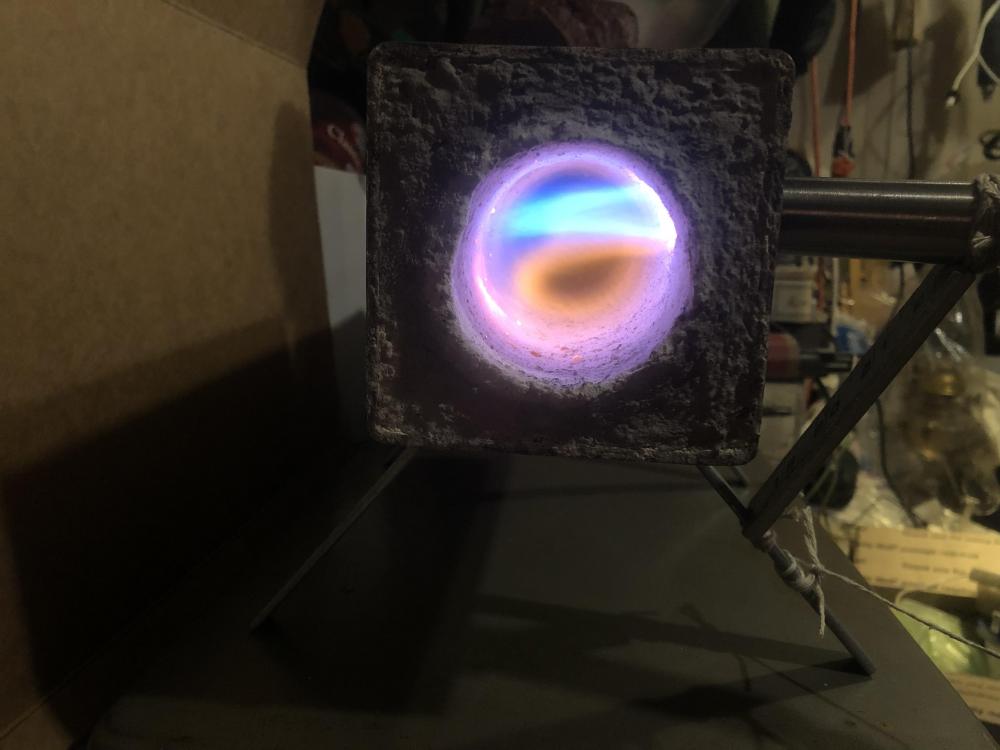

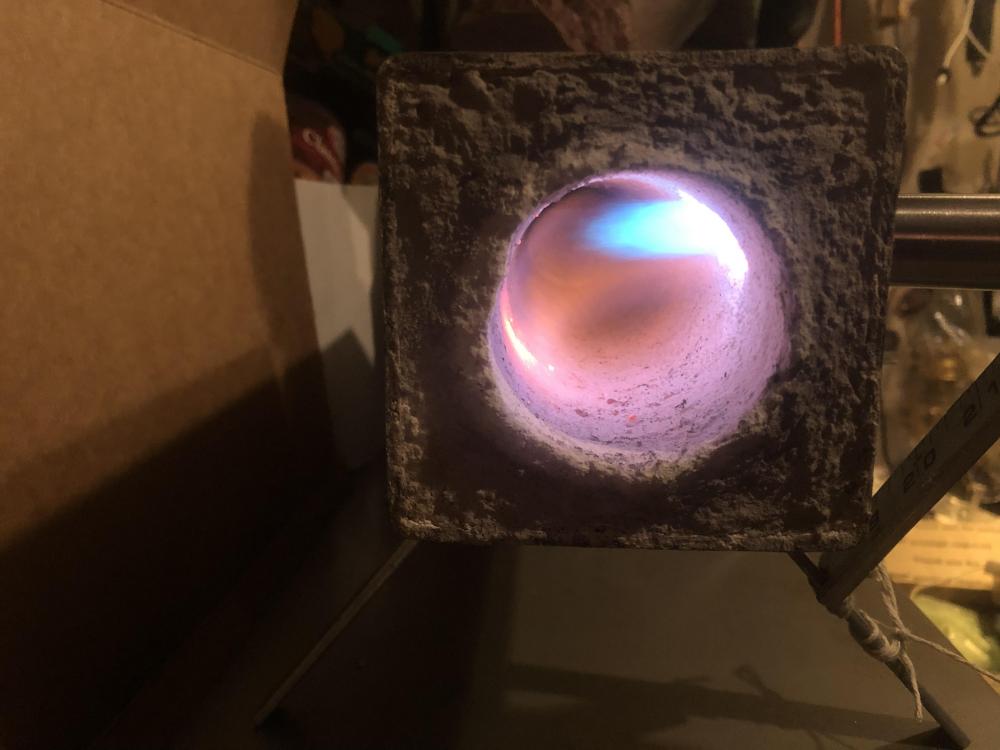

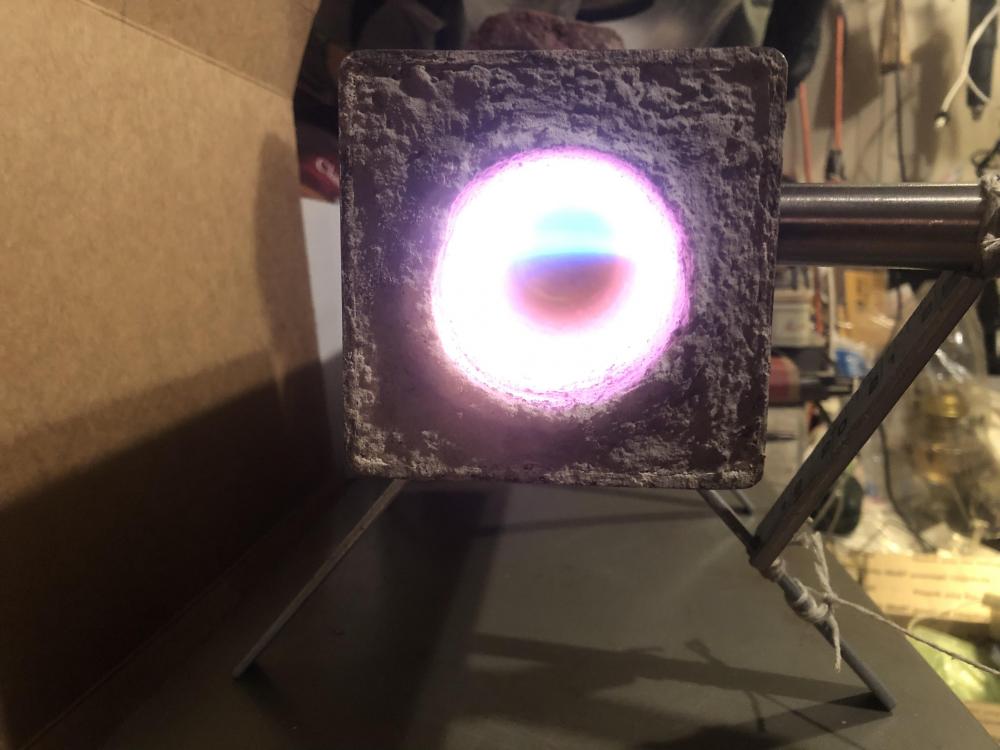

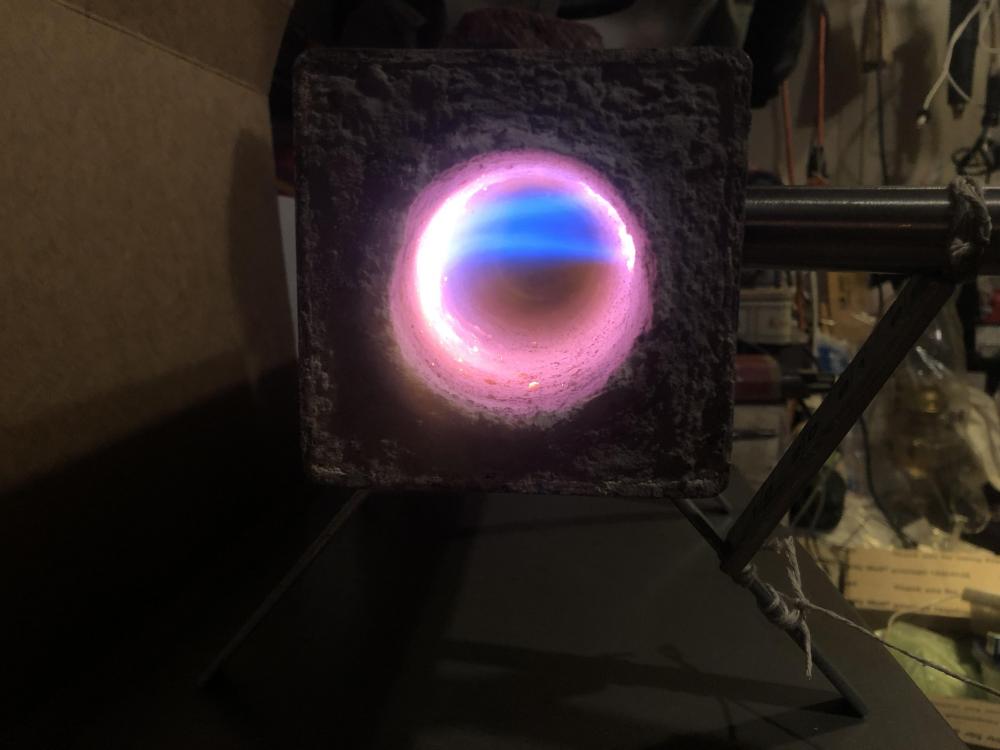

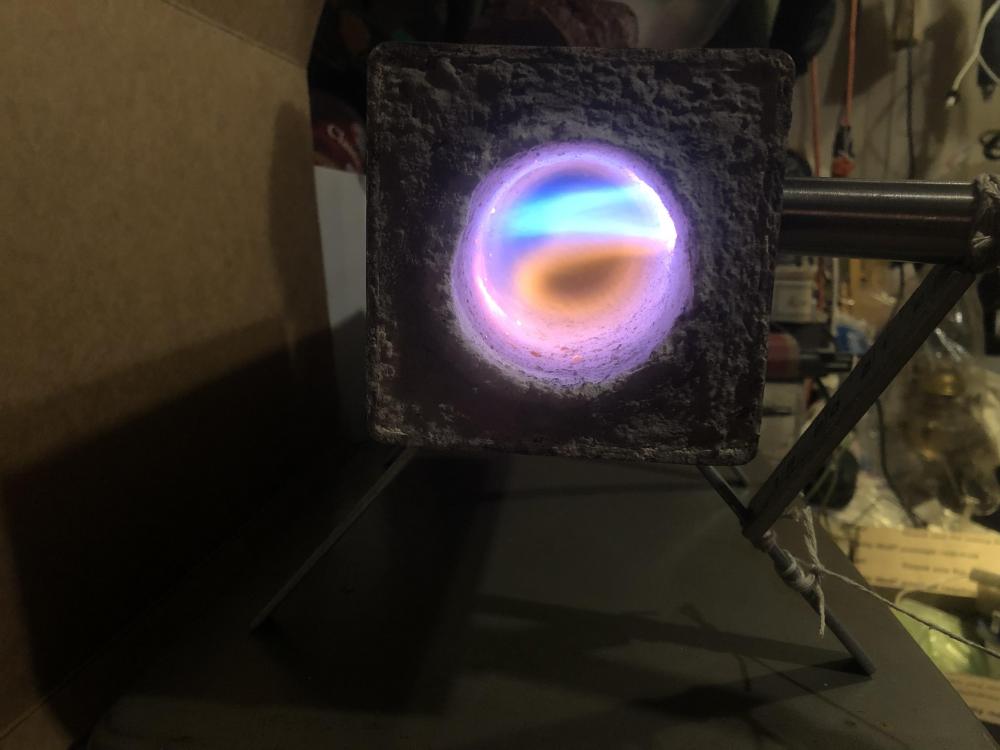

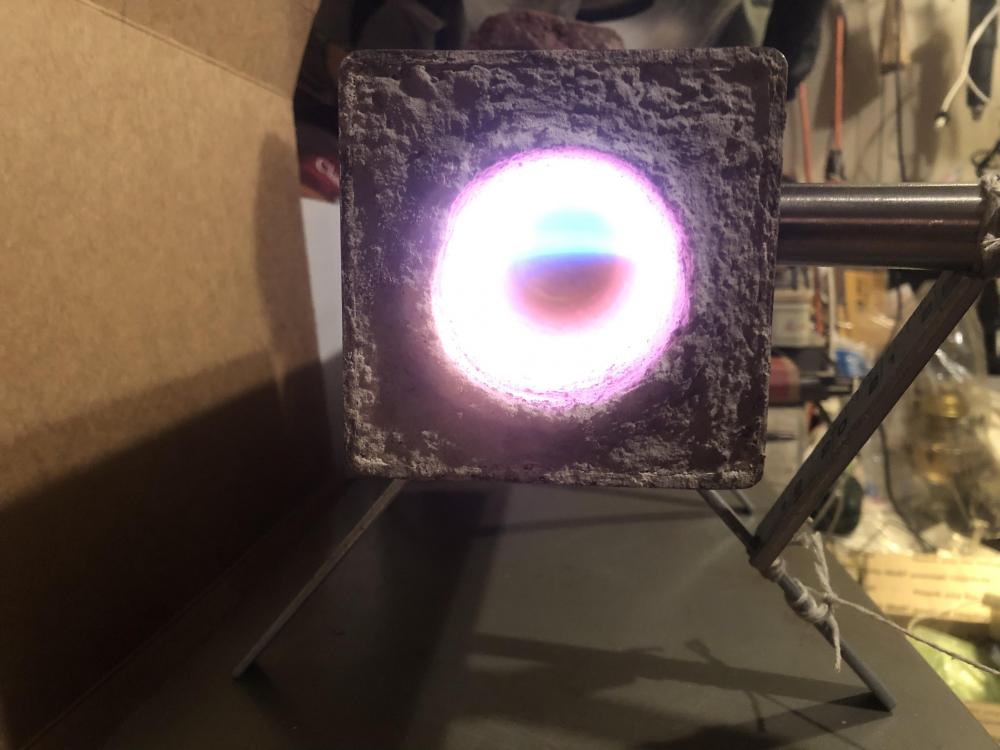

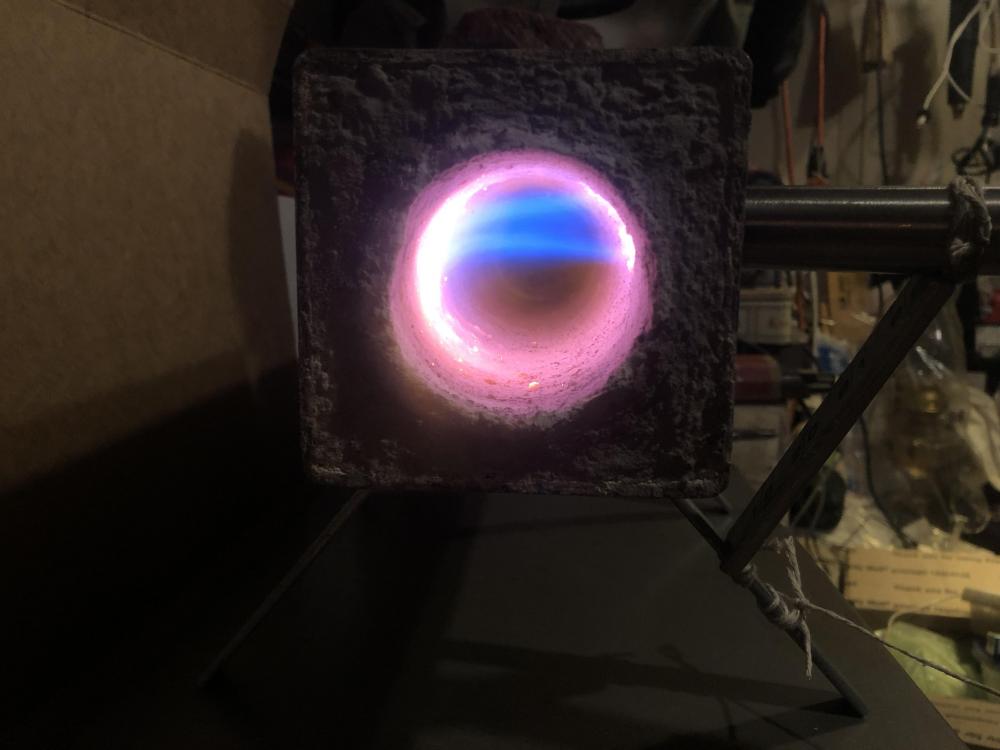

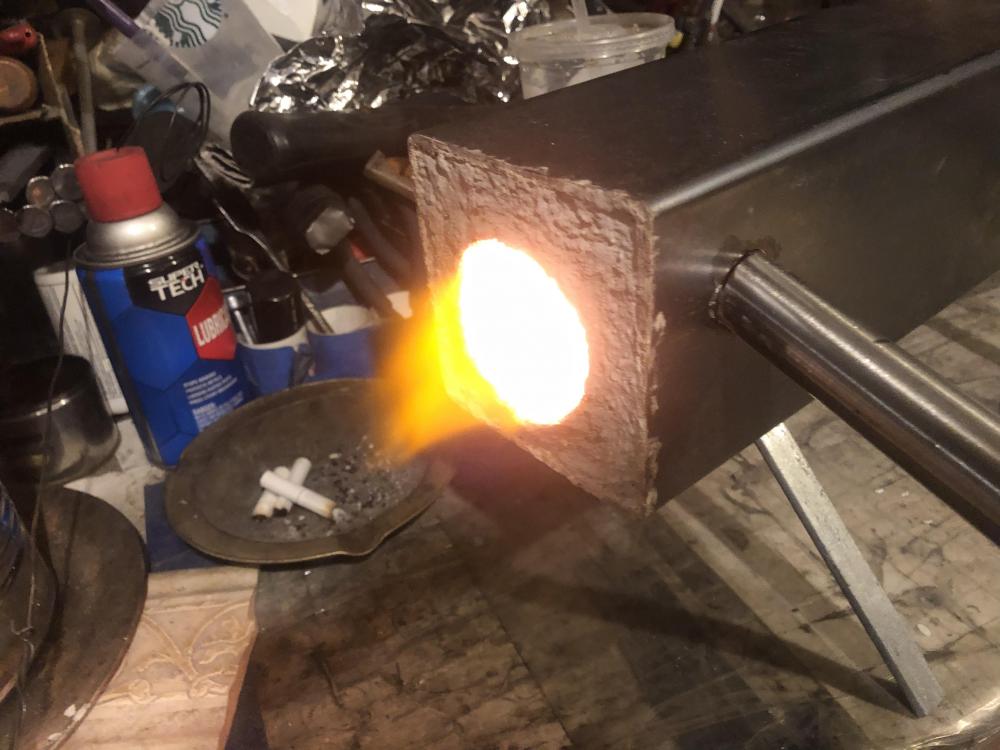

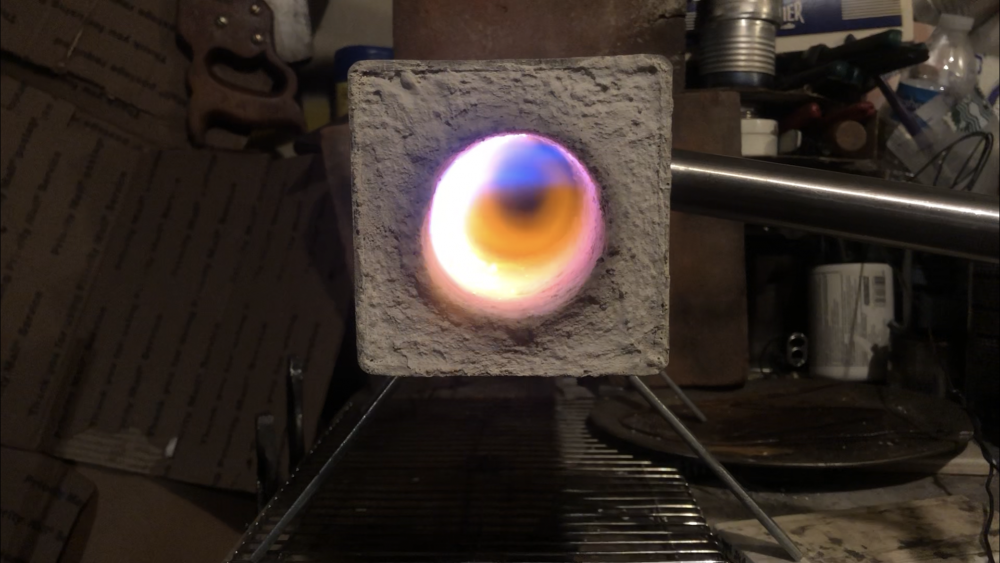

Here’s the flame. Looking better after playing around and adjusting depth ect. It get very hot!! Pictures are from start just out to full power! Also a picture showing flameout the back and front. Is it looking ok?? I never had a production firge so have nothing to compare to?

-

-

Yes the flame is you said. I played around a bit with it and got it to burn decent after a good long while. I think I’ll do the 1/2” t burner soon as I find all the parts. Unless... does anyone here have one already built for sale?

-

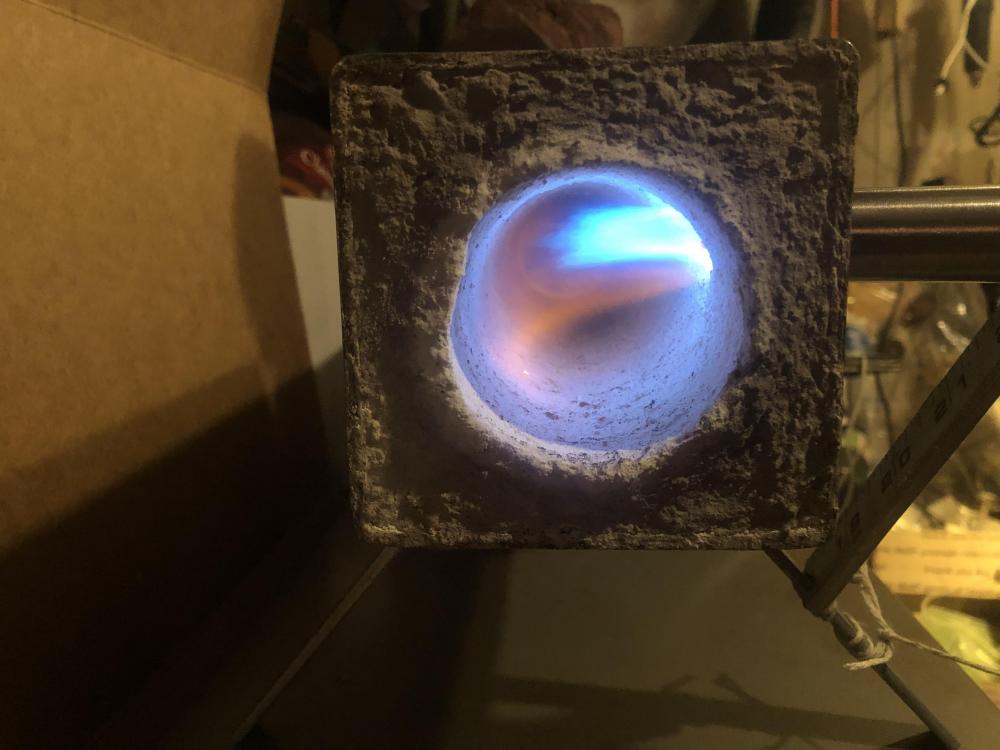

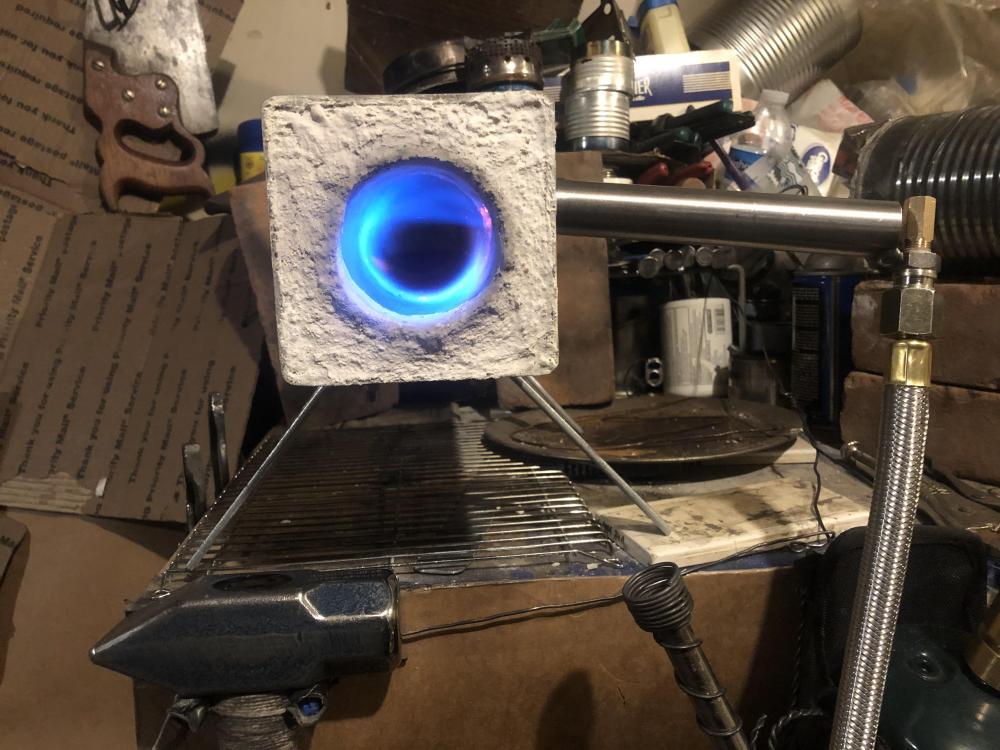

Here’s the first fire! Ran it for 1 minute at just barely on, them about 5 minutes at low medium then after an hour to cool repeated and it’s now at full temp! Swirls great! I’ll play with the different burners but plan on using my torch which I tried and worked good in this forge as well! Inthe pictures you see the atlas 30k burner and atlas 20psi hose. So far it’s been an hour no issues. I’m liking the swirl a lot!

-

Sounds like a plan! I’ll let you know in advance. Won’t be for another month or so.