-

Posts

20 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Dan Mac

-

Hay Chris I'm working on a guy who says he has 2 anvils in his barn he might let go. I've work with him in the past and hopefully he would make me a deal. I don't need 3 so I be happy to pass one along at whatever cost it costs me (if he sells them to me)

-

I was thinking of using a small leaf spring I have kicking around in a bin. I did ask him if he had any other blacksmithing tools and he just looked at me with a funny look. So I don't think think he really knew what he had there.

-

So $20.00 Canadian is really like $10.00 U.S. lol Really the guy just wanted it out of his garage and I was happy to help.

-

Since finding my Anvil I applied the same technique into finding a leg vise mentioning post vise/ leg vise to everyone I ran into. I picked up this little beauty for a whopping $20.00 5" jaw, not sure of the make as I cant see any markings on it. The barbell has a slight bend to it but it functions with very little slop in the thread.

-

Hay Budden Year identification Help

Dan Mac replied to oldlords's topic in Anvils, Swage Blocks, and Mandrels

I do apologize I found the pic on the net and wasn't aware it was from his book. Just thought it was a list a list someone might have put together from publicly published materials. Won't happen again -

Lol, I don't mind a little ribbing from time to time.

-

-

Thought I would add a after pic. looks like there are 2 weld lines. one in the middle and a clearly defined line 0.75" from the top.

-

Did a little research on the number and came up with a year of 1901. Would that be a solid steel verson or the half wrought half steel?

-

I swear on everything I hold dear that it was a matter of being at the right place at the right time. Was talking to my wifes cousins about forging and mentioned that I would love to have an anvil. One cousin had a neighbor who was complaining about having to cut the grass around it, 1 call and i was there the next day... Now I have to start chatting about power hammers and hydraulic presses

-

Thanks I was going to hit the top with a flap disk to take the paint off, but I might go with paint stripper and a wire brush first.

-

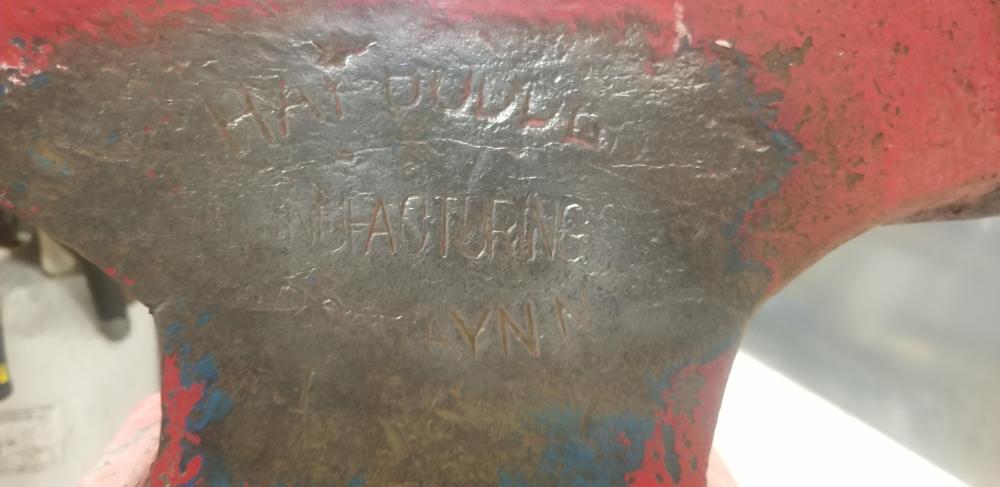

Hi Guys For the last little while I've been banging away on a 200 Lbs block of P20 and mentioning the word "ANVIL" to everyone I know in hopes someone would know that guy that had one in there back yard... Well today was that day. total wt is 152 Lbs. and I was told it was painted to look like a cartoon Anvil complete with hand painted Acme on the side. So I took the wire wheel to it and found this... Any Ideas on what I have? the rebound is fantastic compared to what i have.

-

-

I'm just about to take a wire wheel to the side of it. I can see some markings, I'll post a couple pics soon

-

Just picked up my first Anvil for a whopping $0.00 someone actually painted it to look like a cartoon anvil and put Acme on the side of it... lol but the thing is for all the years it was outside in a garden the paint must of kept it from rusting...

-

Looking for a bit of advice

Dan Mac replied to Dan Mac's topic in Anvils, Swage Blocks, and Mandrels

I will for sure when I take possession of it. The plan is to pick it up in a couple of weeks. As for now I'm trying to absorb as much information as I can. I was advised to start with a wood dowel to develop some muscle memory, concentrating on proper angle form. Can't water to get started... -

Looking for a bit of advice

Dan Mac replied to Dan Mac's topic in Anvils, Swage Blocks, and Mandrels

Thanks guys. The steel block is just sitting on a big burl I'm drying for wood working, it's not its final home I plan on building a wood stand for it. As for hammer control... we will find out as I'm as new to this as can be so I'm sure I'm going to miss as many times as I hit lol. I plan on starting out as basic as I can next is to see if there is anybody in the Windsor, Essex Ontario area that wants some free labour for a little knowledge. Cheers Dan -

Hi all I'm just acquiring the basics to get started so far I was given a 4"x8.5"x12" block of P20 (free) and a solid fuel forge with an assortment of hammers and tongs for $250.00 My question is: Is annealed P20 hard enough for a sub. anvil or would it need heat treating and how should I orientate my anvil? Should I use the 12" as the face or the 8.5" I also was thinking of turning a horn to weld on and machining a step on one side and welding a 1" square tube on the other end for hardie tools. I run a small CNC business from my house so the machining isn't a problem. Thanks Dan