-

Posts

37 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Livingston, Tx

Recent Profile Visitors

-

Naturally Aspirated Ribbon Burner. Photo heavy.

the2ndcashboy replied to Frosty's topic in Ribbon Burners

I always thought it was "if it ain't broke, fix it til it is". -

Naturally Aspirated Ribbon Burner. Photo heavy.

the2ndcashboy replied to Frosty's topic in Ribbon Burners

Ok, good to know. I kind of suspected it was a combination of me leaving too much opening on the forge and also my lack of experience forge welding. I just wanted to make sure it wasn't a FAM issue so I didn't chase my tail excessively. I've known since I built the forge that it gets plenty hot enough to weld in. The pics are after less than 10 minutes of run time, it gets much hotter. Like I said in my reply to Buzz, I took the pictures at a lower heat because the flame is pretty much invisible at full heat. I'll put the shortest mig tip in and do some testing next time I get a chance to actually do some forging. -

Naturally Aspirated Ribbon Burner. Photo heavy.

the2ndcashboy replied to Frosty's topic in Ribbon Burners

The color is pretty accurate, at least on my phone. YMMV of course. That's not completely up to temp, probably 1800-ish degrees. It will easily peg a type K thermocouple (2300) at a very bright yellow color. You can't really see the burner flame anymore at that point though, that's why I took the pics at a lower heat. -

Naturally Aspirated Ribbon Burner. Photo heavy.

the2ndcashboy replied to Frosty's topic in Ribbon Burners

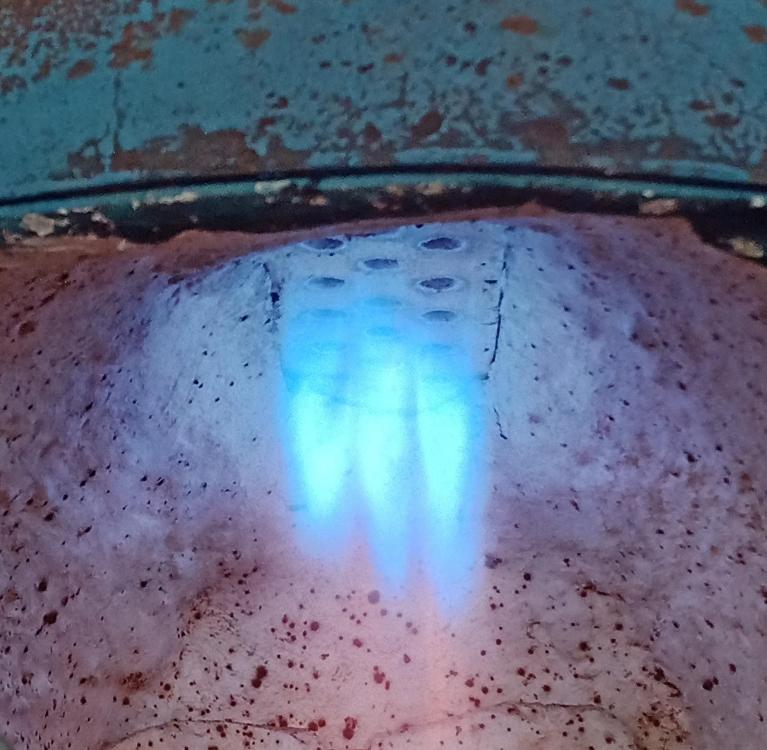

Ok, I took some pics after work this morning. This is a 3/4" Frosty T with a standard length .035" mig tip, 19 crayon-sized holes in the burner block. I couldn't get any dragons breath with the forge cold unless I closed the doors completely, and even then it was faint. There was a bit more with the forge up to temp. The standoff on the burner pretty much goes away when the interior starts to glow. 1st pic: Cold start, 10psi 2nd pic: Cold start, 10psi 3rd pic: Most of the way up to temp (low orange), 10psi 4th pic: Most of the way up to temp (low orange), 10psi. -

Naturally Aspirated Ribbon Burner. Photo heavy.

the2ndcashboy replied to Frosty's topic in Ribbon Burners

I have seen scale form on the stock while in the forge, but it's mostly when I have the doors open all the way I think. Its not something I've been particularly concerned about until I've started forge welding. I've probably hijacked this thread enough at this point. My on-topic original question has been mostly answered (FAM on the NARB is primarily determined by the interaction between the size/number of outlet holes, and the hole size of the mig tip. Mig tip length has little to no effect). I probably should make a separate thread for tuning my particular setup. -

Naturally Aspirated Ribbon Burner. Photo heavy.

the2ndcashboy replied to Frosty's topic in Ribbon Burners

I'm not assuming rich or lean at this point, I'd just like to know what it is so I can work from there. -

Naturally Aspirated Ribbon Burner. Photo heavy.

the2ndcashboy replied to Frosty's topic in Ribbon Burners

I'll get some still pics when I make it to my weekend. I work nights, and pictures of the forge taken during the day won't tell you much due to all the ambient light. As far as the flame liftoff, I don't know if its as bad as it looks in the video. I still get the below-10psi "flutter" when the forge has been running awhile, and from what I've seen in this thread, the solution to that issue is to plug outlets and get air speed up. It also seems like if it's too restricted, I'd get a richer mixture as I increase psi (like buzz was saying), but I really don't seem to. The thing runs remarkably consistent no matter what variables I change. I guess all this is just the hazards of learning something new in isolation. I don't really have anyone in my area that I can go to and say "how does this flame look to you" and trust their answer. The internet is great but no substitute for in person experience. I appreciate you attempting to help me bumble through. -

Naturally Aspirated Ribbon Burner. Photo heavy.

the2ndcashboy replied to Frosty's topic in Ribbon Burners

I built the burner using your original as a pattern, I don't recall the number of holes right offhand. There does appear to be some flame standoff, but I can crank it straight to 20psi on cold start without blowing it out, so it must not be too much of a problem (the forge is basically stone cold in the videos). I don't get much visible dragons breath unless it's running near max pressure. At 10psi there's basically none visible unless I turn out the lights at night, then there's 6" or so of blue flame visible. If I choke it down enough to affect the flame color, the burner gets a lot quieter due to reduced airflow, leading me to believe its not going to put enough mixture into the forge to maintain welding temps. I might just be chasing my tail here anyway. The burner/forge combo work well enough to peg my type K thermocouple at only 10psi, so it's probably just my lack of experience that's messing with my forge welding. I was just trying to eliminate the FAM variable when I ran into the tuning oddity. I actually noticed it when I built another frosty T for my brother with a different type of fitting for the mig tip that moved it deeper into the T. When I ran the new burner in my forge to test it, I noticed the flame had a very slight greenish tint, which I'd never seen out of my NARB unless I choked it almost all the way down. I screwed that burner into my NARB and the flame looked exactly the same as it had with my original inducer. That's when I started digging deeper. Oh well, since the burner doesn't seem to be adjustable, I'll work on the other variables instead. -

Naturally Aspirated Ribbon Burner. Photo heavy.

the2ndcashboy replied to Frosty's topic in Ribbon Burners

Hopefully these video links work. I need to relearn how to post multimedia to the interwebz. Videos are in order from shortest tip to longest. https://drive.google.com/file/d/1Q0SGQ5LSS1cao6wt2BN406LUIdq51d27/view?usp=drivesdk https://drive.google.com/file/d/1Q2G35cGZorZnYDv87s6zoy36YH0RzTSE/view?usp=drivesdk https://drive.google.com/file/d/1Q4DeqM2dZKfy93QWpn8PT0ZSIt8cANKz/view?usp=drivesdk -

Naturally Aspirated Ribbon Burner. Photo heavy.

the2ndcashboy replied to Frosty's topic in Ribbon Burners

So I've run into an interesting issue with my 3/4" T NARB. I built it to the original plans some time ago, and it works great. It will run from <1psi up to the 20psi max on my regulator. It does start to burn back after about an hour if I'm running at less than 10psi, but that doesn't really bother me enough to apply the fix. My issue is that it doesn't really respond to adjustments of the mig tip length. I was trying some forge welding for the first time and I was struggling with scaling. Part of the problem was me leaving the back of the forge open like an idiot, but I've kind of suspected all along that I'm a little on the oxidizing side of FAM. I started experimenting, and so far I've ranged from a standard .035 mig tip cut down to about half its original length, all the way up to a double length mig tip that protrudes down into the throat of the T a ways and the flame doesn't seem to change at all. Now, if I take that same burner and lay it in the forge without the ribbon outlet, I can get a wide range of flame colors (FAMs) by adjusting mig tip length. The only way I can get the flame to change on the ribbon is to block about 75% of the inlet area. Even completely blocking one side of the T makes no difference at all in flame color. I'm baffled. -

Arm & Hammer or Trenton?

the2ndcashboy replied to the2ndcashboy's topic in Anvils, Swage Blocks, and Mandrels

No, the base was rusted pretty heavily. Nothing that will hurt function, but it's pitted too deeply to see any numbers. -

Arm & Hammer or Trenton?

the2ndcashboy replied to the2ndcashboy's topic in Anvils, Swage Blocks, and Mandrels

Sorry, had to go to my desktop and edit the post to add pics. Yeah, the indentations under the heel are what makes me think its an A&H. I'm not that knowledgeable about anvil history though, so I thought I'd get more learned opinions. -

Picked up this anvil the other day. I believe its an A&H, but there are no remaining markings at all. The sides have been beat on quite a bit and the base has lost some metal to rust (looks like it probably sat in something wet for a few years or decades). Dimensions are: 120lbs, 3-5/8"x15" face, 25-1/2" overall, 1/2" pritchel, 7/8" hardy (I think. It's a hair under 1" so I'm guessing with wear it was originally 7/8".), 10-3/4" height, 9-1/2"x11" base.

-

That looks a LOT like the presumptive Badger I picked up awhile back on the cheap to repair. Badgers are supposed to be better than Vulcans, but this one didn't weld very well, even with the special cast iron rods ($$$). Lots of fizzing and burning in the weld puddle. That one is still functional, but I wouldn't pay 375, and don't count on being able to repair it in any way.

-

Naturally Aspirated Ribbon Burner. Photo heavy.

the2ndcashboy replied to Frosty's topic in Ribbon Burners

My NARB would run at 5psi for about 30 minutes and then start popping. At first I turned the gas up, and that worked, but then I got smart and just opened the doors up all the way. Now it runs @ 5psi for hours at a time, at a nice yellow heat.