Peppie

-

Posts

228 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Peppie

-

-

BeaverNZ,

There is less than a 1/16" movement from side to side on the ram table. The ram eye is inset to the ram guide block. I am confident that it will not bind.....but I have been wrong in the past....once.

Thanks Jspool. I will post a video when she breaths.

That's a great idea Frosty. I will crush a can opening day.

Got my lines connected. Only took me 5 trips to the hose store.

Waiting on my parts to hook the pump to the motor.

Sparky will be here in a couple weeks to energize the press.

-

Even if you were to pay a welder , you could build your own for less than 4600.

-

Ty Frosty.

Going to name HIM "Popeye ". I found a vinyl sticker to use as a pattern to etch a steel plate. It shows his huge forearm. Hope that's not to cutsy???

Should have my hydraulics hooked up this week. Then I will fashion a foot control.

More pics to come.

I guess I am going about this in a safe and not outrageous way. Haven't had any comments that insist I am doing something terribly wrong.

Peppie

-

-

I was shocked to find out the cost of my hydraulic lines, fittings, and assembly. It was near the same amount I payed for my 5" cylinder!

-

Thanks bubba.

I agree. Size doesn't matter. "So they say". It's all about " the force". Lol

I way under estimated the cost of hydraulic fittings,hoses,and assembly labor! It is as much as what I payed for my 5" cylinder!

-

-

-

-

Question for those who are following, that are in the know.

I have a 4 way 3 position valve with no indents and will return to neutral when the handle is released. Prince item # 2010. It is fitted with a center spring. This valve was recommended in Batson's book. He states that the valve will need to be balanced, to be used as a foot control. He doesn't go into detail on how or why it should be balanced. What does that mean? And how is it done?

Also if I were to use quick disconnect fittings for the hydraulic system. Will the fluid drain out of the hose when I disconnect it from the unit?

-

-

-

Lol, eutrophicated1, I will keep my drill press TY the press won't be in the shop. It will be placed next to the outdoor covered forge area.

I plan to use the heck out of this press .

-

-

-

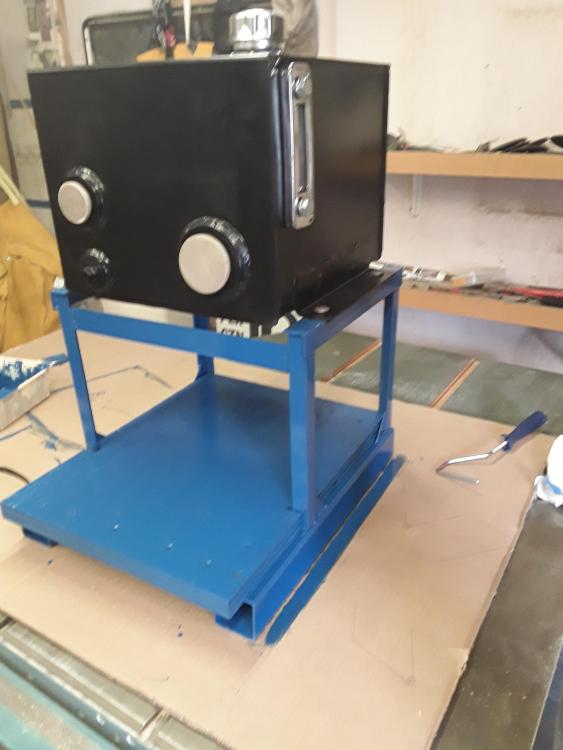

Got alot done this weekend. Built a mobile cart for the power pack. The motor , and pump will mount below. Waiting on the mailman for my locking swivel casters.

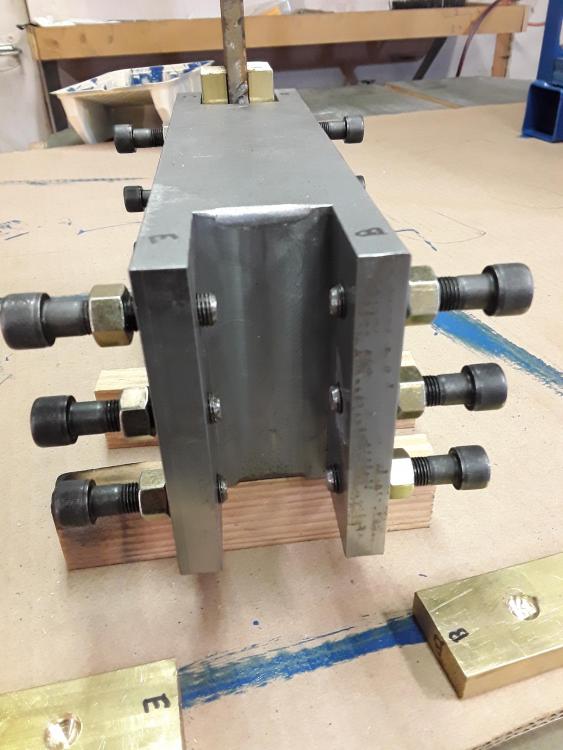

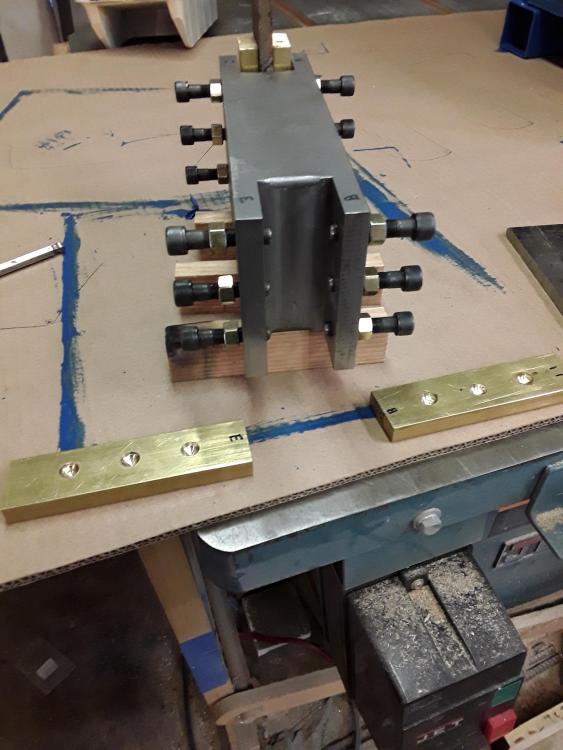

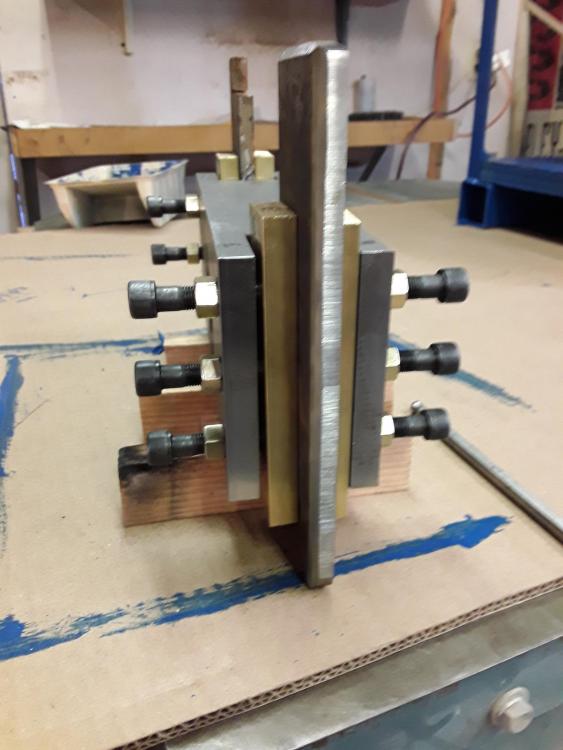

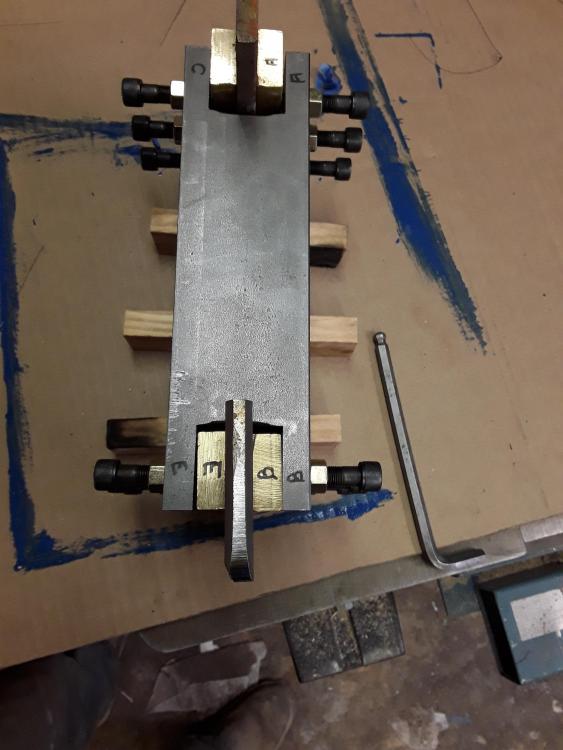

Was also able to work on the guide block. Wanted it adjustable, and able to replace the brass when worn. 3/8" X 24 bolts with a jam nut. Wondering if I should attach a spring to the brass, back to the block to keep the brass snug to the bolts. Or am I over thinking?

-

-

Thanks for the responses.

I do take Everything I read on the net with a grain of salt.

Thru my own research ( and consulting with an electrician friend)on some of the products listed above, I feel the best option for my situation will be the contractor.(DOL) It will be rated for 7.5 hp. It will run in conjunction with a 35amp on off switch.

-

Looking for a switch for a 5hp 1ph 230v electric motor. Would like the switch to have an emergency paddle off button. There seems to be many different ratings on these types of switches. I dont have a clue on which will work.

And is there a supplier that offers this "on-off" switch mounted in a metal box? Can't seam to find said item, after a lengthy search on line.

Hhhhhhhhhhelllllllpppp. Please

Peppie

-

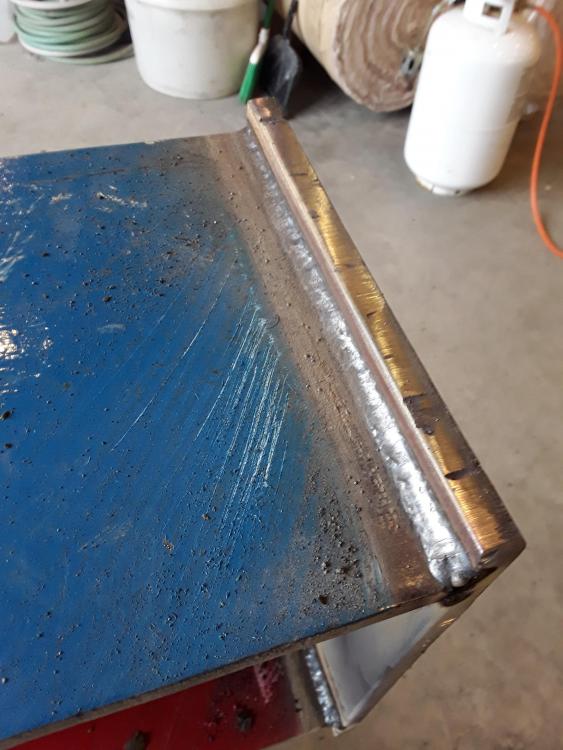

The guy doing my welding has done it professionally as a union iron worker for the past 30 years. I have all the confidence in the world that the welding on this project will be the least of my worries .

I really believe there will be " No " on my guide block.

-

The gap between the guide and the webbing is 1/16" overall.

The guide block will have a 6" x6" x 1" platform welded to the top of it, as shown in the above picture.

Thanks for the feedback.

-

3 hours ago, Jspool said:

Combo “T” dies are great. Your presses ability to run off center work will depend upon the play and engineering of your guides. If your upper die cants, your billet will banana as it is drawn out

Jspool. After looking at the above pictures... do you think the engineering is sound enough to press material off center?

-

I know there has to be a few experienced press operator/builders that have been watching this thread. Looking for some input please.

In the above photos you can see my ram guide block. It is machined to inset around the top ram pin mount. I had this shape as such to keep the ram plate from tilting from side to side. Didn't want the guide to get jammed between the webbing.

Question is...will I be able to use dies that are approx 2" off center? Such as a fuller die mounted beside a flat die?

-

I have been looking at different designs as well. I will cross that bridge at a later date.

Pressing Forward........Thoughts???

in Presses

Posted

Little saftey work today. Ya never know when some hot $h*! May ruin your day.