Peppie

-

Posts

228 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Peppie

-

-

My background is in woodworking. This heat and beat thing is very new to me.I have spent the last 6 months planning, organizing,and building a 10 X 10 covered forge outside my "wood" shop.

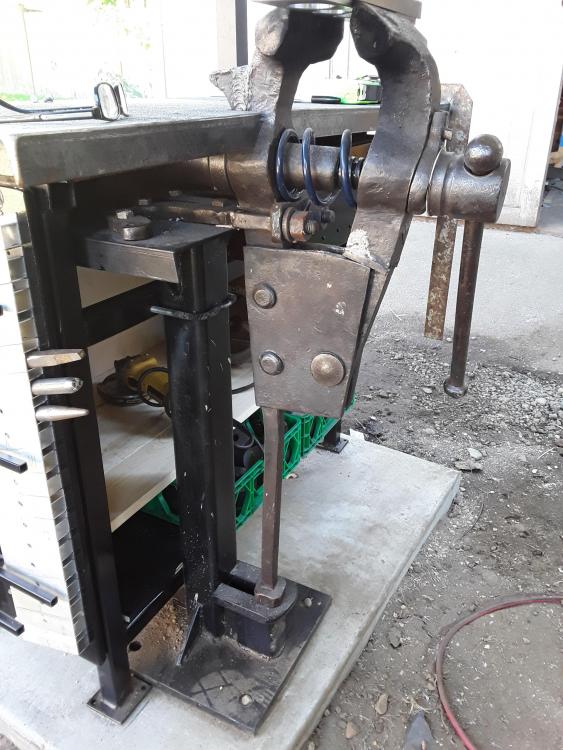

This is my latest addition to the forge. Being my covered area is small, all benches and tools need to be compact and versitile.

To me the greatest acomplishment of this project was getting all four feet to touch the ground when I turned it over.

-

11 hours ago, MC Hammer said:

Is that cedar that's in the ground? If not, I'd be worried about the wood rotting or getting termites / carpenter ants. Otherwise it looks great.

Yes it is cedar. If it lasts 10+ years...... I will be close to being to old to swing a hammer. LOL. I have worked construction all my life, and my body is sore and tired.

1 hour ago, MC Hammer said:Irondragon - yeah I just hate to see anyone go through all that work and make something that nice and sunk that deep only to have to rip it all out down the road. My very large stump has never moved on me and if you router out the bottom so it has 3 sort of feet it never wears and starts rocking. I doubt I'll ever see that stump give out.

I wouldnt dig up the stump if it went bad... I would move the anvil, as in digging a new whole. LOL

4 hours ago, Frosty said:A delightful level of overkill, nicely done. My only suggestion is to round off the corners before you discover why by banging your shin or other body part on one.

Frosty The Lucky.

Once I get the chance to spend some time sweating over it I am sure I will find some sopts that will need the grinders attention.

-

Do you think it is over kill for a 300 pounder??

-

The stump is buried 30'' in the ground.

The steel tube is 1/2 wall thickness. approx 100# and lagged to the stump tendon.

80# of sand.

5/8'' top plate

300# PW is inbedded in a think bead of silicone.

The chain was left over from the tie-down, so I wrapped it around the waist.

Went from a high pitched "Rinnnnnnnggggg" To a dull thwap.

-

2 hours ago, Frosty said:

It's in great condition Peppie. PROVIDED it passes the rebound test, it is possible it went through a fire and the temper has been completely drawn on the face. Re-hardening an anvil is NOT a trivial task.

Frosty The Lucky.

TY Frosty, The rebound is at 80%. Less on the heel .

1 hour ago, ThomasPowers said:The edges are almost suspiciously sharp; might check them for welding/grinding. Very good condition!

Looked very closely after I have taken the wire wheel (knotted 4'' grinder) to it and no signs of any welding repairs.

-

37 minutes ago, ThomasPowers said:

Learning that the search function native to the forum is not of much worth and how to use a browser search function here instead is a really good thing...You may want to read more of the hits yourself...

Thanks. I plan too. I was focused on a Columbian anvil. But ended up comming home with this one. I will be reading up on this beast.

What do you think about the condition it is in??

-

4 minutes ago, ThomasPowers said:

So I googled: peter wright anchor site:iforgeiron.com and got 80 results

including this one from 6 years ago:

Posted May 14, 2012

Richard Postman, the author of Anvils in America believe that they were inspector's marks. Peter Wrights had numerous different stampings on the front feet and anchors were one of the common stamps.

Thanks ThomasPowers for the info. Seller said it was pulled from the shipyard, I was reading way to much into that statement from the seller. LOL

-

-

Bought a 300# Peter Wright this morning. After I took the wire brush to it I found the "Peter Wright". But no other markings. Once I got down to the front right foot I seen a small 1'' X 1'' anchor stamped in it. I was told the anvil was pulled out of Todd Shipyard 30 years ago. Anyone ever see the "Anchor" stamped in a Peter Wright?

I am working on getting some pictures posted up. I am a computer idiot.

-

My stump is 48'' tall X 24'' diam. 24'' of it is buried in the ground. I have used it this way for a couple months and I find myself haveing to lean in to get to the anvil (small RR track).

I also have a 12'' X 12'' X 1/2 wall thickness, that is 23'' tall. Weighs about 80-90 lbs.

My plan is to cut the stump top (above ground) to form a 12'' X 12'' X 8'' tall tendon. Slide the square tube over the tendon, lag it in place.

What should I fill the remaining void in the square tube with? rebar and Concrete? sand?

I plan to use chain and turnbuckles to hold the anvil (what will be new to me a 233 lbs. Columbian) down to the square tube.

Do I need to weld a top plate to the top of the square tube?

Can the top plate just sit on top of the squ. tube with a bead of silicone. And be held in place with the turnbuckles?

If I use concrete will it add mass to the bottom end of the anvil?

-

Hi there 4elements, the start of this summer is very very busy for me . I will be getting into the NWBA by summers end. I need to get some training so I dont start off with bad habits. LOL

-

9 hours ago, ThomasPowers said:

Looks to be in excellent condition and should hang out at the upper end of the price range for your area.

I thought the same thing. I am going to pounce!!

38 minutes ago, Irondragon Forge & Clay said:We won't remember this once leaving this thread, hence the suggestion to edit your profile to show location because so many answers depend upon it.

There that's better. Done!!

-

39 minutes ago, ThomasPowers said:

I believe there is nothing to prevent you from copying the CL photo from CL to your device and then posting the photo here.

As I understand it this site does not exist to provide free advertising for others so by divorcing the photo from the sale you should be ok; Mods? (I even think it would meet fair use rules...)

I was able to figure out how to post the pics see above. LOL

-

7 minutes ago, JlBlohm said:

Any pictures of the Columbian?

Sure wish I could post some up. The seller is running an add on the local CL. From my understanding I am not allowed to post them up here. I have looked at hundereds of anvils on line and seen the conditions they are in. On a scale from 1-100 this one IMO is an 85. The face is flat. the chips on the edges are less than 1/8 '' and very sparse.

-

Maybe I am thinking about this all wrong. From what I have read and heard, the more mass under the hammer the better. So my thinking has lead me to believe that bigger is better. So now that boils down to Price per pound, old versus new. Are the new anvils that more superior in quality and material than the better known older anvils?

Used in good condition Columbian 230# $920= $4 per pound.

This new list I will add $100 on the price for shipping

Mathewson 150# $950 = $6.30 per pound

Rhino 240# $1460=$6.00 per pound

Emerson 200# $1500=$7 per pound

JHM 260# $1450= $5.50 per pound

Nimba site is down But their 85# I beleive is approx $950

So I know we are in some ways comparing apples to peaches... but am I out in left feild here??

Is the Columbian that much of a lesser quality than the new ones to justify the price??

-

7 minutes ago, ThomasPowers said:

Can't discuss the cost without knowing location---Singapore dollars? Canadian Dollars? Australian Dollars, American Dollars? All different.

I think that's HIGH if American dollars and would have to know the location, condition, style---Columbian did some double horned anvils for instance, weight, etc

Not know which of the 100+ countries participating on this forum on the World Wide Web all I can say is you can get large ball bearing other thataway. (however in the USA I'd suggest asking heavy equipment repair places, implement dealers, mechanics---especially truck mechanics)

BTW did you read the thread on improvised anvils? there has been over 2000 years of blacksmiths smithing on things that don't look like a London Pattern Anvil and only about 200 years with them using London Pattern anvils in a fairly small subset of the world. Far better to buy a chunk of steel from the scrapyard to forge on and spend the $100's on a good postvise and tongs.

I am in the US. Just south of Seattle Wa. In this area I have seen Price per pound much higher than 4$. Thanks for the info on the ball bearing I will look into those location. It is not a double horn, I have pictures of it, and it is a London Pattern. ( I would post a pic.. but it is offered on CL)

-

TY for the response guys. I am new to this game, and would like to buy a quality anvil at a fair price. The face looks to be in good condition. Very small limited chips on the edges. The seller is asking 4$ per pound. From my reasearch that is a fair price. Cant find a new 200# er for near that cost.

Where would I find a 1/2'' to 1'' ball bearing to do a rebound test?

Anything I should check for when I go to view it?

-

The upsidedown triangle has the letter C inside of it. Anyone have some info ?? weight is 233#, Face in good condition. Is this anvil forged, with a hardened plate on top? Is it soild all the way thru??

-

3 hours ago, BIGGUNDOCTOR said:

I have a 125# JHM Journeyman, and it is a nice anvil. Ductile iron.

excessive quotes removed

The JHM Journeyman was my first selection. But then I started looking a bit harder, and came up with a couple that were not Ductile iron. I am not real sure if that is going to make a big difference in the quality and proformance , compared to the alloys used in the Nimba , and the Rhino. I only want to buy once. I dont mind spending a bit more if it will make a differance in proformance and longgevity. I will do some research on the Holland brand next TY

3 hours ago, swedefiddle said:Good Morning, Peppie

You live in an area that is a center of the North West Blacksmith Association. .. More excessive quotes removed

Thanks for the local info. I plan on getting more active, once I get my shop all tooled up. Retierment is comming in about 2 1/2 years. I believe this hobby will suit me well.

-

Mid range to me would be approx. 125#-180ish. I have no need for something over 200#. I looked at the Nimba. He is also semi local. Not crazy about the double horn shape. But it is still on my radar.

-

TY Iron Dragon. I have been lurking here for months. i used the "Gas Forge" thread to research my Forced air forge I build last Oct. It seems to be that the info you get from FB pages is all over the map. I think 80% of the repies are from people who dont know crap1 Way to much misinformation be thrown out there. I found good soild info here. There are a few here that know what they are talking about. That being said I thought it best I return here for solid info on my next project.

Stockmaker, TY for the feed back. I am in the Tacoma area. Shipping would be about the same cost as driving over the hill, less the 10-12 hour drive time. Not many anvils in that weight to price catigory out there on the market. Seems like the sweet spot for my budget. The special alloy used to forge this Rhino caught my attention.

-

Looking for some feedback on a 140# Baby Rhino anvil. I am in th market for a med weight anvil, and this anvil came into my research.

Any info will be appriecated.

.thumb.jpg.96a6f41cff0d7b838c3d096d7fd64483.jpg)

My new work staition

in Building, Designing a Shop

Posted

Runners are rated for 100 lbs