Peppie

-

Posts

228 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Peppie

-

-

Frosty,

That is were I was going wrong on my search.. My terms for my search were to wide spread.

Your cookies are on the way. I've read enough on here to realize your bark is sometimes to the point. At times that is exactly what needs to be brought to someone's attention. I myself dont like to have facts surger coated.

Kizzy, thanks for the info, it is very helpful. I am trying to decide if my wallet is fat enough to go this route .

I just finished a 24 ton press build. I enjoyed it so much, I am designing another 16 ton. Thanks again

-

Did a search last night, and came up empty. All I found was hydraulic powered water pumps.

Thanks for the reply Frosty. BTW. I prefer soft Charmin for a .......wipe.

-

Designing a press. Look for a site that sells an in tank hydraulic pump. Also looking for motor size to power such pump???

Peppie

-

Was reading a post from 2016 last nite. A member here related to a ribbon burner manufacture mentioned a flare at the end of each burner port . Seems easy enough to do...But he also mentioned that the length of the port and the depth and diam of the flare was important. He did not offer any numbers. Maybe a trade secret??

Would there be a big difference in burner performance? Or am I just splitting hairs as a hobbiest?

Peppie

-

TY Mikey,

I also enlarged the front pigeon hole, and fabed a small hood for it. Still need to make the rear door a bit larger....maybe. It is only there for a pass thru.

-

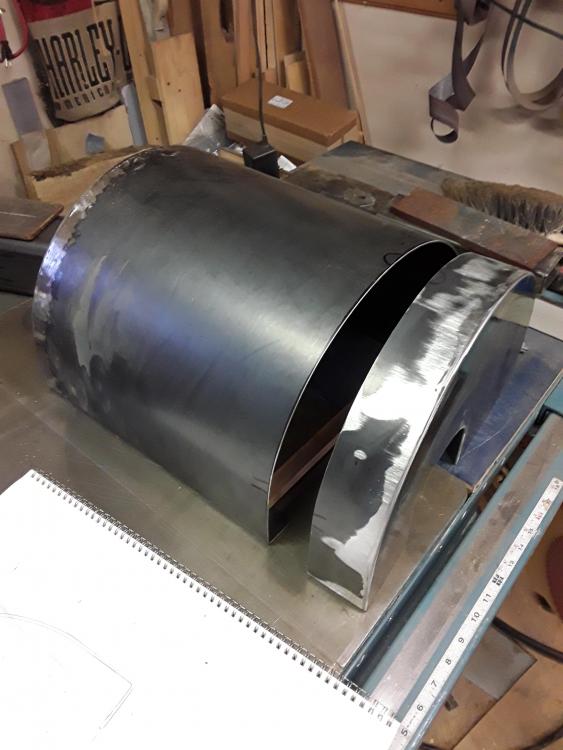

Fab work completed. Ready for paint. Wanted a soft self closing door. Got all the bugs worked out.

-

-

TY Mikey98118,

Not to late to adjust. Easy fix.

-

The back one is 2 1/2 X 4, the front is 4 X 6. What size would you suggest? I sized them based on work fitting in and out. I have a forced air forge that has a small opening in the front, doesn't seem to make the shell hot enough to do any damage.

-

Thought I would share this build with ya all.

After much research, and some great advice from some very trusted members here, I have decided to build a floor mounted ribbon burner forge.

Total inside cubic in ( after wool,and refactory) will be approx 400 cubic in. The burner will have approximately 20-24 ports (crayon diam) 3" X 8". Fed by 2" pipe. Air supplied by a kiddies bounce house blower.

Two layers of 1" X 8# X 2600 degree ceramic wool. 1/2" Mizzou refactory, and then plistix 900

-

Want to use soft brick for my forge door. Want to be sure my Mizzou will stay put on a vertical application.

Peppie

-

-

Will do Frosty, when I get home. Sounds like your computer has the flu

-

Jaspool, yes and no. Yes for punching holes. Also helps to keep the ram shaft from being over extended. I think k it is better for the ram if there is 1/2 to 1/3 of the shaft still in the cylinder while working

-

Materman,

I have read the same info. I plan on increasing the intake pipe, compared to the total square inches of the port holes. .... With in reason. Will try to work in 1/2" diameter increase.

-

I did a search for the twisted birthday cake candles.... didn't think they were long enough at 2.5"???

-

Ty Frosty

-

Will the refactory " Mizzou" stick to koawool insulation board?

-

I am going to learn by ya-alls mistakes.I have down sized the "single" chamber to 380 cubic inches. Knocked 400+ cubic inches. It will still be a floor mount ribbon burner, 2" X 8" with 24 holes. Total length of the chamber will be 12".

Here is the question, has anyone tried using the bendable straws for the burner ports? Would like to direct the ports e it away from the curved side wall . Wouldn't need to bend the straw anymore than 10 degrees at the most. Can I burn the straws out? Or do I have to pull them out?

-

Lol Irondragon,

I wear a set of radio-earmuffs. Gotta have my rock-n-roll.

TY

-

Bubba this is definitely a labor changer!

Played with it all day today. Going to take some time and practice to get a good feel for it. Managed to ruin a billet of Damascus I had started by hand a while back. Was all good until I tried folding it over, instead of cutting, grinding,cleaning, then welding. Lesson learned!

-

Thanks Beev,

Thought about increasing the pump size, but would have only increased the second stage speed by less than a 1/4 " per second. Splitting hairs at that point.

-

Big THANK YOU to Frosty for the crap on my tidy forge wall

All funny things aside. The start up when off without a hitch ( less 2 small fitting leaks, nothing a wrench didn't fix).

Very proud of this project. It was way out of my wheelhouse when I first decided to build. But with some deep research and a bit of hard work, it turned out as I had envisioned.

The pump is still set at factory spec.(1500 psi) I will leave it there until I get use to the press.

-

Submersible single stage hydraulic pump?

in Presses

Posted

Holy cow!! My wallet isn't that fat!! If I were to go that route with a 5 hp unit..... I wouldn't have any cash-Ola left for hoses and fittings!