Jonathan Smidt

Members-

Posts

49 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Jonathan Smidt

-

Damascus Hammer Pendant

Jonathan Smidt replied to Jonathan Smidt's topic in Metal Sculpture & Carvings

Nope, though that sounds like a great idea! The guy I was taking lessons from mentioned I could take it to a jewlry shop and try to get it gold/silver plated, and then blue it as well, to give it a three layer effect -

Damascus Hammer Pendant

Jonathan Smidt replied to Jonathan Smidt's topic in Metal Sculpture & Carvings

Thanks tkunkel. And Thomas, only did 3 etches into it, just enough for the texture that it catches your fingernails as you slide across it, but it's still really nice and smooth. It is currently sitting with my car keys now, until I can get around to making a chain to wear it from....but, I really dislike forming jump rings, so that might be a little while away. I really was more curious how it would turn out, as last month we made a 30 inch bar of Damascus, but I haven't been able to get to the shop to forge it. So, on Saturday, after my lesson covering a bladesmithing tips, techniques, etc, I pulled out the bar, and worked on one of the ends, that I already knew I wasn't going to incorporate into a knife. Hammered it out pretty randomly with a rounding hammer, to mix the pattern up a bit more, did a hot cut, and then took the disc of material I had made to the belt grinder for some quality hogging haha. Probably a bit more explanation than needed...but I was excited to be playing with it this weekend....Life's been waaayyyy too busy for me lately :( -

Not sure if this is the right place to share this, but here goes... Used some of the excess from my damascus billet to make this little damascus hammer pendant 120 layer random pattern 1095 and 15N20 Flattened the metal out with a rounding hammer, then used a belt grinder to create the little hammer. Sanded to 400 grit, then did a few cycles in ferric chloride/distilled water. Final cut added hydrogen peroxide into the acid. All of this was done at the shop of the Master Bladesmith i am training under VID_207690720_135150_454.mp4

-

Bwahaha, I'm sure my time in Afghanistan has already exposed me to my fair share of unhealthy cancer causing fun, I'll make due note to not intentionally ever work with anything in the metalworking field that can harm me. My jewelry class, and now the welding courses I've been taking, are helping me, as well as all of you on here!

-

"Just sort of potentially lethal" Lol is that all? yeah, I'm just going to stick with the basic nonferrous metals that I've learned on now, and be really careful about getting caught up in anything that might make my health go south haha. I started this bladesmithing thing a little later than I would preferred anyways, don't need health problems slowing me down!

-

Thanks for the heads up! Wouldn't want to make anything poisonous to the wearer haha

-

That was definitely nice of him to do! I don't know why, but I've felt the breed of individuals who chase after and show an interest in these older arts/crafts, have a level of appreciation/respect I suppose, than most individuals do these days. I haven't met anyone in the metalworking world yet, that has left a bad taste in my mouth

-

^Buying old silver coins from pawn shops seems like a great idea! I know my jewelry teacher mentioned she would go to yard sales/pawn shops and look for old pieces to either melt for metal, or harvest good stones from etc. My blacksmith instructor also mentioned finding scrap sheet metal for copper working etc could be a potential cheaper way than buying pristine sheet metal from jewelry supply shops. I'm all for anyone's old handy ways of tracking down materials at a cheaper cost!

-

Thanks for the advice! I'm sticking to mostly copper right now anyways for nonferrous, in order to keep my production costs down. Don't want to ruin the pricy metals due to inexperience (already accidently melted some silver bezel wire.... oops). Mind you, while I have really enjoyed the jewelry aspect here (and will likely continue it), the main purpose I have for learning all of these tricks is to enable me to transfer the skills over for some finish work on future blades, really enhance the guard/hilt, etc

-

I was thinking of trying some simple copper/brass mokume gane to get the process down. Will keep those others in mind for when I feel my skills are ready haha, still learning a lot, taking it slow

-

which metals are you referring to? I staysway from zinc lol, and the only thing Ive used Aluminum for was a piece I was riveting lol

-

-

I purposely was adding the color after I had finished with. I forged them, quenched em, then cleaned them up a bit. After that, I reintroduced the head of the spike to the heat, to playwith letting the colors creep on it (something I would never do to a high carbon blade, would ruin my heat treat)

-

Was able to get out to the forge for a few hours this weekend. Hadn't been out in a while, so decided to mess around with some RR Spike knives to get the rhythm back and just work on some rough shaping etc. Below is the result!

-

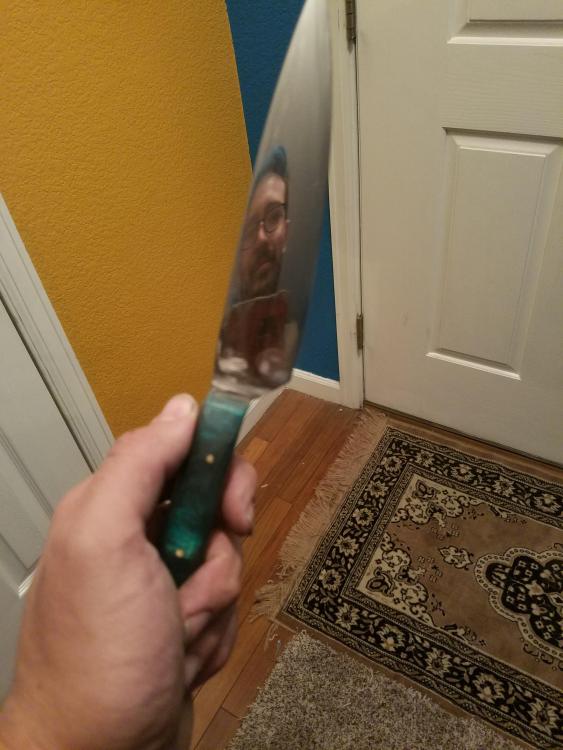

Definitely having a blast! Though the weather hasn't been kind and has kept me from getting as much forge time in as I would like. I continue to try to take local classes whenever I get the chance, and am pursuing more blacksmithing classes on top of it to work on those skills. Also went back to college for Welding, Machining, and Metalsmithing/jewelry courses, hoping those skills I will be able to transfer over to my bladesmithing! Also, while I don't know if I will be able to get to it this year, I want to try to get to the ABS bladesmithing and handle/guard classes. Till then though, I'll just continue to practice, and share my updates with everyone here! It now resides in my Mother-in-law's kitchen. She was in need of a sharp kitchen knife, and after I sent her a video of that knife slicing cleanly through some chicken, she asked for it! So, one less random sharp object in the house...just means I gotta make another one for myself! haha

- 8 replies

-

- bladesmithing

- beginner

-

(and 1 more)

Tagged with:

-

@will, thats the top of my phone case, I would be too scared to post something with a major flaw like a crack if it was that large haha. I just got a belt sander for christmas, so was trying that for the ricasso and plunge....gonna take some getting used to I think. Definitely plan to practice a lot more on those!

- 8 replies

-

- bladesmithing

- beginner

-

(and 1 more)

Tagged with:

-

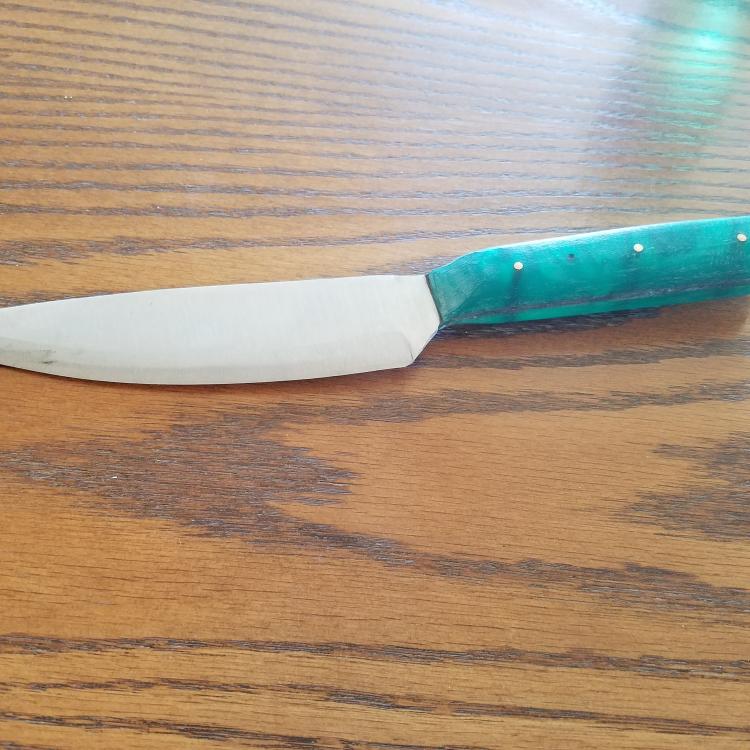

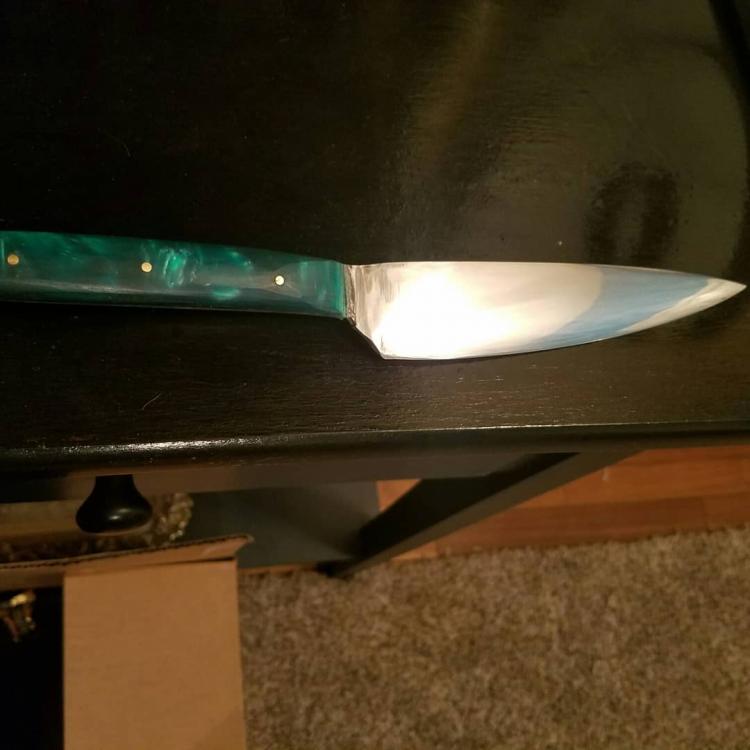

Slowed down a bit over the holiday timeframe, finally getting some time to share with ya'll my continued journey towards being a bladesmith! Behold knife attempt number 6! Blade is 1084, handle material is inlace acrylester. Used my belt sander up to 1000, then took it by hand up to 2500. Pins are brass. *Note: Still working on the other one....going to try to get better bevels into it.

- 8 replies

-

- bladesmithing

- beginner

-

(and 1 more)

Tagged with:

-

Gorgeous Knife! I am extremely envious of your skill good sir.

-

I present to you....knife number 5!!!

Jonathan Smidt replied to Jonathan Smidt's topic in Knife Making

Thanks, I'll go get the gauntlet of grits from 60/80 up, and try to see what I can make happen! -

I present to you....knife number 5!!!

Jonathan Smidt replied to Jonathan Smidt's topic in Knife Making

If it's in one of the archived-esq ones I haven't gotten to reading through those yet, I'll try to poke around and see if I can dig them up -

I present to you....knife number 5!!!

Jonathan Smidt replied to Jonathan Smidt's topic in Knife Making

^When doing it by hand, does the blade get clean and polished with each grit of paper as you go up? and is it better to sand wet or dry? A lot of these I've just been going through trial and error with. I have 220-2500 I can use to hand sand, but not sure what it should look like at each stage before moving up in grit. -

I present to you....knife number 5!!!

Jonathan Smidt replied to Jonathan Smidt's topic in Knife Making

Frosty, not going to lie, of all the types of advice/comments I was expecting on this post, I must say, photography advice was not one of them haha. That being said, I shall take your advice and put it to good use, I suppose just taking single snaps with my phone to post really don't provide the best images to allow people to best observe and critique my work haha....maybe I'll break out the wife's camera...got her a Cannon EOS 60D a couple years back that needs some dusting off hahaha. -

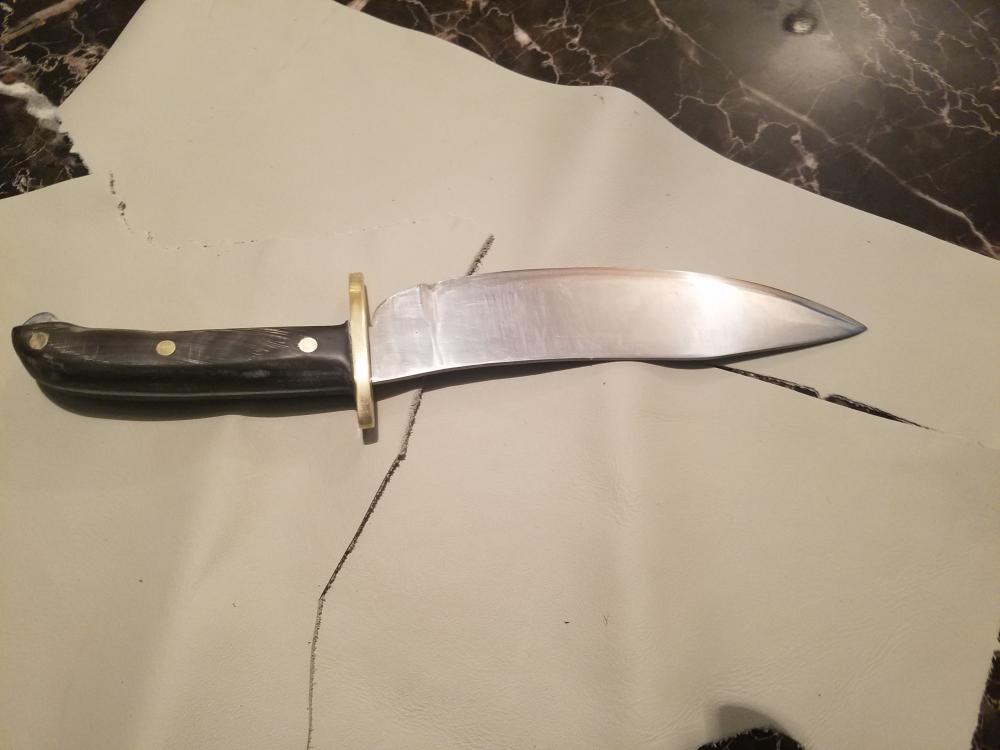

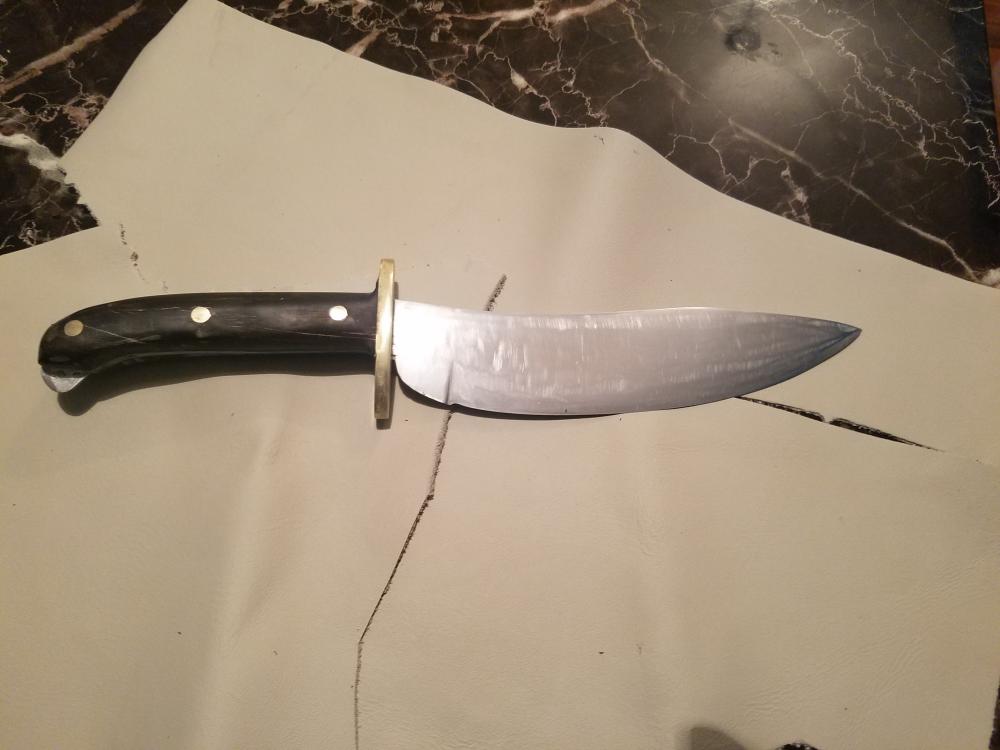

Hey all, forgive the many posts of knives of subpar quality, but with each post, following the comments I get here, I feel I am better able to grow in my quest to become an at least decent bladesmith lol. That being said, without further a do, I present to you knife number 5 (gonna give it to my dad for christmas) Blade is 1080 steel, guard and pins are brass, and I uses buffalo horn for the scales. As always, criticism and comments welcome and appreciated!!

-

Adding to the list of things to get! Thanks!!!

-

Roger that, I"ll grab some of those and see how it goes, learning a lot of this on the fly as I go, which is why I'm asking all the questions...so far all I've really used a file for was to check hardness, and to attempt to file out a hidden tang, and to clean up some pin holes before I got my drill press set up (used a hand drill, broke some bits, and just filed the rest of the hole so the pin would fit lol)