-

Posts

14 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Jakob Bull

-

Ok cheers that was very interesting and helpful, I did think the burner tube length might interfere with the flare and was wondering if it would allow the flame to burn inside slightly but was hoping it would stabilize the flame and stop it oscillating as much. it dose seem to help at lower pressure tho. Also not that I'm going to but if I was to polish the internal bore my hypothesis is that it would help with stability of the flame but might create a mixing problem. What do you think?

-

It dose have a taper at the end if that's what you mean by a ''retention cup''?

-

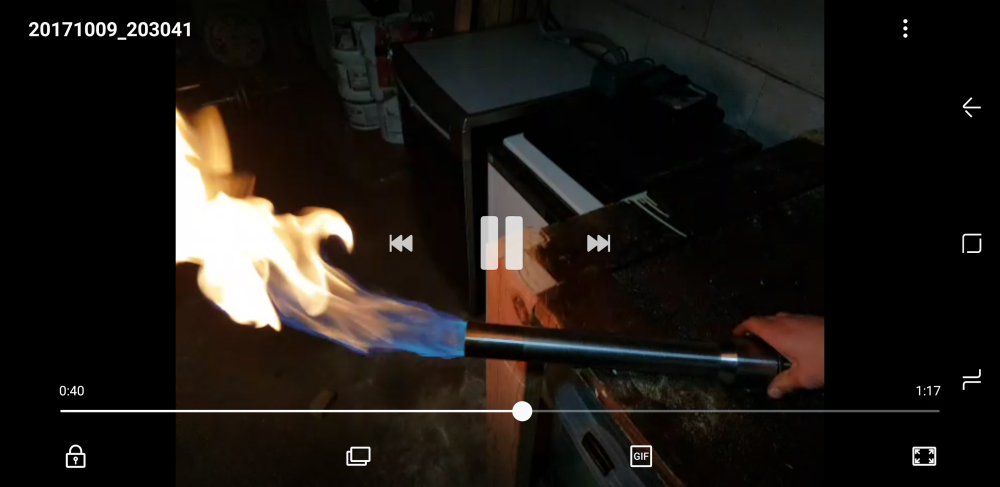

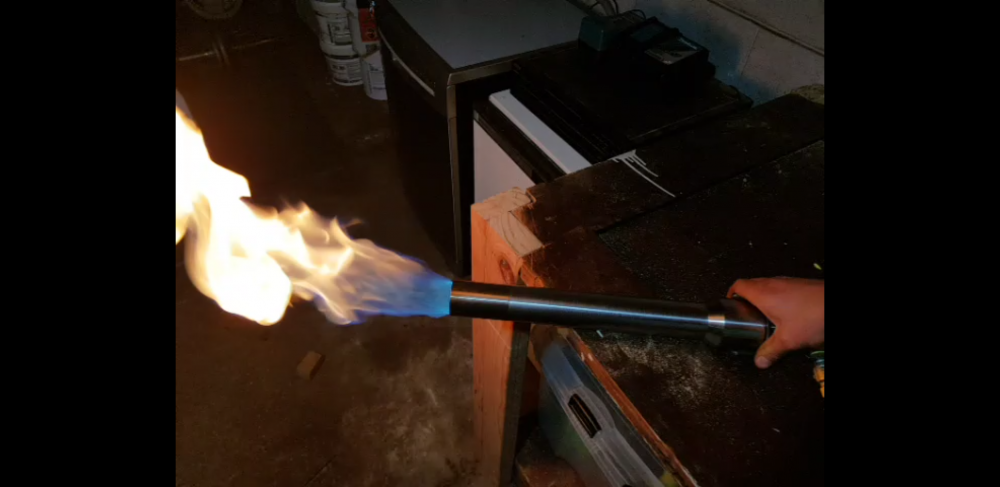

This is it running at 2psi then I turned it up to 10psi I can't open the air any more or it will blow out what I want to fix is the turbulent flame or is it running ok? 20171009_203041.mp4

-

But it is still blowing out when I open the air all the way and I have increased the orifice to 1mm

-

Hi Mikey I do have it all plumbed up properly now those pictures were just to show what type of shape I have

-

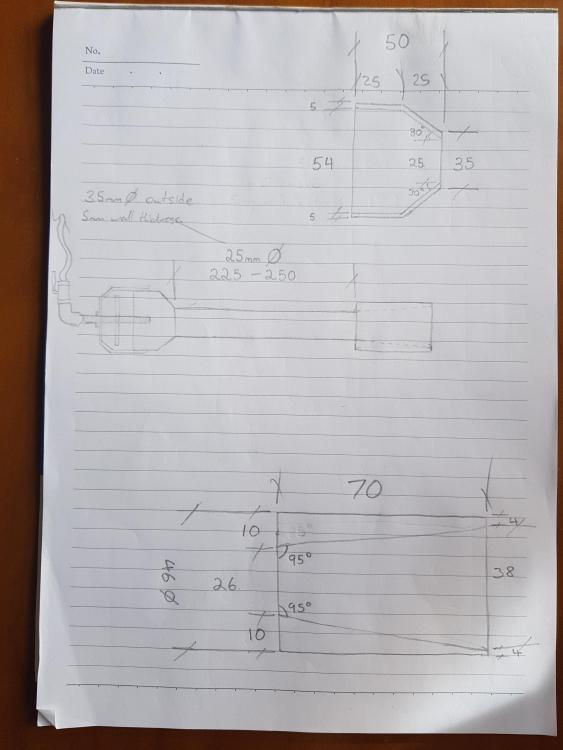

Hi all iv built a vanturi burner and it has a problem I think. it lights fine and runs fine (no sputtering) but when I open the air vent(Just a thumb screw to open and close the top)I can't open it any more then 3mm or it will blow out when I lowered the pressure to 2-3psi I could open it slightly more but then same results. Can anyone help me? I can't find anyone with this problem maybe it isn't a problem just a very small window of adjustability thanks for the help in advance. (Iv added a drawing of what all the dimensions are.) Sorry forgot to add my gas orifice was 0.6mm then I swapped it for 0.8mm that worked better. do I just need to increase that again to decrease the pressure difference and slow the air intake or am i over thinking it.

-

I think you are right it looks like a 2 haha

- 14 replies

-

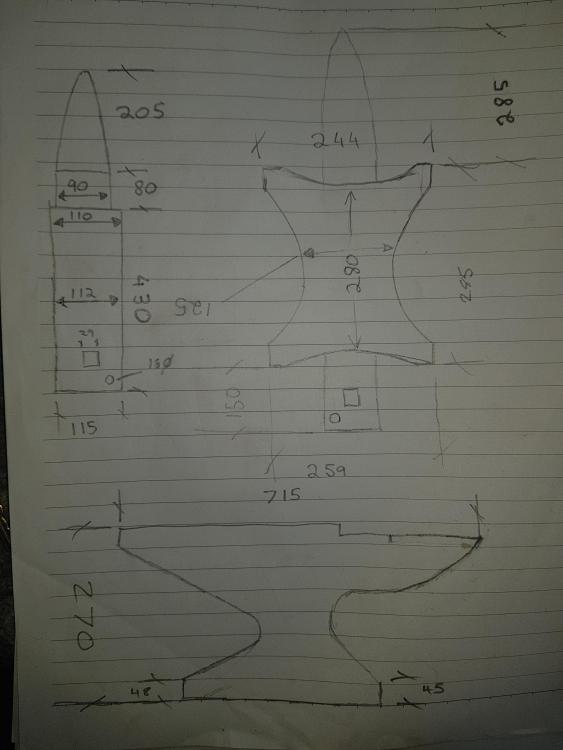

Ok thanks i didn't even see the weight marks before zooming in on the picture above I see 1.9.1 but am unsure about the 9. But that would make it around 96.5kg and it definitely feels that heavy, I'll have to weigh it properly

- 14 replies

-

Here's some pictures after i buffed it, i can't see any marks but I'm not to worried what brand it is just interested and wondered if anyone could magic up an answer for me haha

- 14 replies

-

Hi no I haven't done a rebound test yet as I don't have any ballbearings. Yea I did ALOT of research into anvil stands and liked the steel tripod as I can stand with my feet under it to get close on small jobs so I made one as heavy as I could afford haha it's almost as heavy as the anvil.

- 14 replies

-

Cheers, don't worry I would never grind the face the bottom was grounded so I could fill some low spots then I milled it flat as I have a steel base with a rubber gasket.

- 14 replies

-

Hi all. I want to identify my anvil I live in New Zealand but my anvil came from Birmingham England (told by the original owner before me) i have wire buffed and found only one mark in the middle of the front foot I will attach photos. Thanks for all the help in advance.

- 14 replies