-

Posts

11,858 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Irondragon Forge ClayWorks

-

-

38 minutes ago, Chad J. said:

Made a nice little calla lilly as well. Actually best I've made yet.

Bet that would fit right in the bouquet we are trying to get made for Glenn's memorial.

I can't control the wind, all I can do is adjust my sail’s.

Semper Paratus -

Welcome to the club, but mine was roller skating.

Welcome to the club, but mine was roller skating. I can still hear my ex wife laughing and that the rink floor is really really hard.

I can still hear my ex wife laughing and that the rink floor is really really hard.

-

As I understand it's use, the stone mason who was dressing the large flat stone grindstone's, he/she would use that hammer to cut the groves in the stone deeper by setting the sharpened peen end in the grove and striking the other end, hence the mushrooming on both ends. I once saw that being done in an old restored mill. Thought it was interesting the mason used the same rhythm as a lot of blacksmith's.

I can't control the wind, all I can do is adjust my sail’s.

Semper Paratus -

Have you tried doing a search as suggested it the Read This First thread? I did and got 32 results with the first one you did in '23. What else did you want to know?

I can't control the wind, all I can do is adjust my sail’s.

Semper Paratus -

There is no "right" answer to many/most questions. In the case of your straight peen hammer, I would say it has been used a lot and ground to that shape by a long ago smith who needed/wanted one shaped like that. Put a serviceable handle on it and enjoy.

Now my question is. What does that hammer have to do with V swage's?

I can't control the wind, all I can do is adjust my sail’s.

Semper Paratus -

Good link Scott, I've bookmarked it in case I run out of rabbit holes to follow.

I can't control the wind, all I can do is adjust my sail’s.

Semper Paratus -

My intro to blacksmithing as a child was listening to my grandfathers exploits about his Army deployment with Gen. Blackjack Pershing in the Mexican campaign, chasing Poncho Villa around the southwest. He was a blacksmith that was reassigned as a mechanic when the Army was transitioning to mechanization from mules & horses.

Jump forward several decades, when we would come to the Ozark’s and visit Silver Dollar City in Branson MO. There was a working blacksmith there who’s name was Tiny Robinson (if I recall) and any time my wife would look for me she knew where to look. I remember one time he was demonstrating how to make a Russian wrapped rose and it fascinated me how he could make the metal move into a beautiful rose.

Now jump to 1984 when I was a rookie police officer working the midnight shift. There was a working blacksmith shop in the town. One morning before sunup, I saw a red glow coming from one of the windows and thought someone had broken into the shop or there was a fire starting. Well while checking it out, it was a fire and the blacksmith was just starting his day firing up the forge.

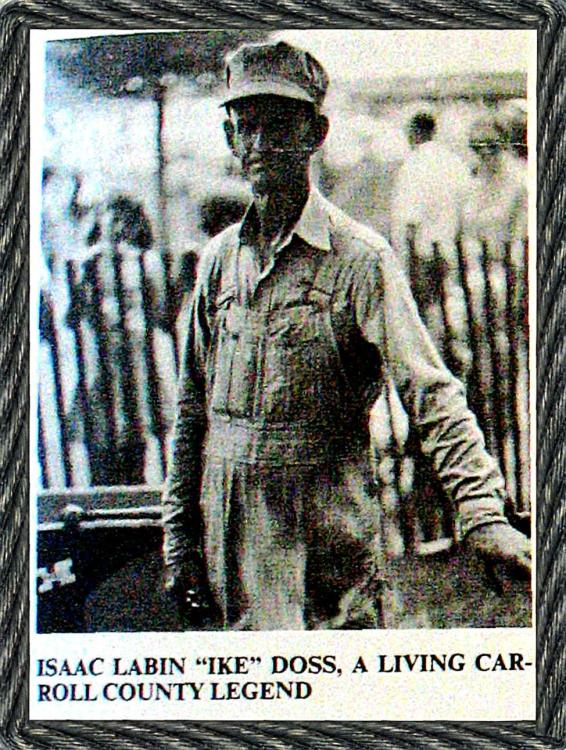

Hence my introduction to my mentor Isaac (Ike) Doss. We seemed to hit it off right away and I learned he was a master smith with some of his work in the Smithsonian Institute and he had given many demonstrations there in his younger days. He was 84 at that time and still working six days a week. He would walk carrying his lunch box, the six blocks from home to the shop. He taught me how to build and maintain a coal fire and a lot of basics of blacksmithing. He also told me how to make my own bottom blast coal forge, which I still use to this day.

Now comes the hard part. One morning, I was detailed to a traffic accident involving a pedestrian on the city square. I immediately saw it was Ike who had been hit and EMS arrived at the same time. Ike never recovered from his injuries and passed away in 1991. For a lot of years, I didn’t have the heart to fire up my forge. Then one day I needed a part for my old tractor and forged it with some of the knowledge he hammered into my head. That along with my wife becoming interested in blacksmithing/bladesmithing and there is again coal smoke on our mountain.

BTW she is becoming an excellent knife maker. Sometimes she will use a knife blank I forged and turn it into a very good knife. I don't like all the finishing work involved and she is a perfectionist so my rough blanks get their proper due.

-

I agree with Frosty, it's a hammer used for dressing the large grinding stones in a mill, for grinding wheat or corn into flour/meal.

I can't control the wind, all I can do is adjust my sail’s.

Semper Paratus -

1 hour ago, Frosty said:

Then this morning Iforge has an issue for a while and takes a while to settle

I think it was an update to version 5... appears to have gone smooth.

I can't control the wind, all I can do is adjust my sail’s.

Semper Paratus -

Welcome from the Ozark Mountains.

Looks like a very good Fisher and a good shop weight. You got a steal of a price at $1.16 U.S. per pound, if it passes the ring & rebound test. Although Fisher's are very quiet anvils and don't ring like a bell, main thing the sound when tapped is consistent over the hardened steel face. Hope you have read about not doing any grinding, milling or welding on the face which will do more harm than good.

All she needs is a wire wheel cleaning and a coat of BLO to keep away the rust and hot steel hammered on her to shine the face right up. I believe the F N is for Fisher Norris the foundry that made it. If I'm wrong I bet Josh who is the owner of the Fisher Norris museum will correct me.

I can't control the wind, all I can do is adjust my sail’s.

Semper Paratus -

I have so many things it is hard to decide which to put in. As far as blacksmith stuff I would say my grandfathers 21/2 lb cross peen hammer, which I use myself. Just picking it up gives me a feeling of connecting with him again. It's on the left next to the anvil.

Then there is the Ozark hoe that was made by my mentor Isaac (Ike) Doss which I make copies of and a framed copy of a story about Ike.

Last but certainly not least is a shadow box of family ribbons & stuff. The Sargent chevron and 4 buttons are from my Great Grandfathers Civil War uniform, in the 23rd Ohio. He was promoted to Captain at the battle of Antietam , along with a copy of a letter from his commanding officer Rutherford B. Hayes (future President). The LT. Bars and tie claps belonged to my father when he was on the police force. The two ribbons belong to me from my service in the USCG (Vietnam & Good Conduct). Bottom left a medal awarded my Grandfather by the French WWI and my uncles expert rifleman pin WWII.

-

I've seen adds for them and they came with a hand cranked Buffalo 200 blower.

I can't control the wind, all I can do is adjust my sail’s.

Semper Paratus -

Old joke, When I nod my head...hit it.

I've never had a striker work with me and I doubt I could remember all those signals. I have trouble remembering what I had for breakfast a lot of the time.

I can't control the wind, all I can do is adjust my sail’s.

Semper Paratus -

I knew I had seen the story, along with others and it took a while to find it but here it is.

https://www.iforgeiron.com/topic/68905-blacksmithing-stories-from-myth-legend-and-folktale/

I can't control the wind, all I can do is adjust my sail’s.

Semper Paratus -

42 minutes ago, Frosty said:

see if I could make a fold up trivet

I think Jenifer made a video about that and a post about making some more, really good looking trivets.

I can't control the wind, all I can do is adjust my sail’s.

Semper Paratus -

Welcome from the Ozark Mountains.

I have made some hammer heads out of sucker rod ends, which if memory serves is 4130, quenched in warm peanut oil and tempered back to blue. So far they have held up well, although I have to admit not using them a lot.

I can't control the wind, all I can do is adjust my sail’s.

Semper Paratus -

Welcome from the Ozark Mountains.

There are several threads about the 660 &6660 downdraft forges. Here are a couple.

https://www.iforgeiron.com/topic/41869-how-do-i-vent-this-buffalo-forge/

https://www.iforgeiron.com/topic/70074-buffalo-660-down-draft-forge/

It would help to have some pictures of the forge and area where you want to locate it. (we love pictures). How complete is the forge? A blower in the duct work should solve your problem, don't blame ya for not wanting to run that long of a stack.

I can't control the wind, all I can do is adjust my sail’s.

Semper Paratus -

6 hours ago, Les L said:

I’m getting the implants,

I had mine done last July, you will be amazed at how much you have been missing. My implants brought my vision to 20/25 and I only need cheater glasses to see fine print and real close work.

The only draw back is now when in the shop I have to wear safety glasses. Before the surgery my bifocals had safety lenses so I always had them on. Be careful when using the forge or a torch, glasses that stop IR are a must, along with sun glasses when out in the sun or driving.

I can't control the wind, all I can do is adjust my sail’s.

Semper Paratus -

I have 7-8 history articles bookmarked, which relate to historical blacksmithing, 4 of which have been submitted by George N.M.

I can't control the wind, all I can do is adjust my sail’s.

Semper ParatusMaybe pinning this thread would work.

-

Here is a thread about the black powder splitting wedge. I have one around somewhere if I haven't loaned it to someone.

I can't control the wind, all I can do is adjust my sail’s.

Semper Paratushttps://www.muzzleloadingforum.com/threads/black-powder-wood-splitting-wedge.142919/

-

I shoveled snow off the front deck and half way up the walk, before the cold got to me and I went inside to warm up. It never got above 8°F with a wind chill of -17°F, not used to that kind of cold, even with my cold weather parka on.

I can't control the wind, all I can do is adjust my sail’s.

Semper Paratus -

Our slack tub is a deep cast urethane sink that was gifted to us. I usually pull the plug to drain it, unless I expect to need it soon. Always drain it when cold weather approaches.

I can't control the wind, all I can do is adjust my sail’s.

Semper Paratus -

6 hours ago, Mothman_c3w said:

good boot jack designs

I did a google search for bootjack styles and came up with this, lots of images here.

I can't control the wind, all I can do is adjust my sail’s.

Semper Paratus -

5 hours ago, Mothman_c3w said:

boot jack

That's all I've ever heard them called. I usually make them out of old horse shoes & flat plate or sometimes wood as a base. Yours look very good. I'm also happy to see I'm not the only one who has to hang on to something when using one(grin).

I can't control the wind, all I can do is adjust my sail’s.

Semper Paratus

Got first v swage

in Swage Blocks

Posted

By golly, I believe you are right. A good thread about them.

https://www.iforgeiron.com/topic/54577-fiskars-4lb-straight-pein-hammer/

I can't control the wind, all I can do is adjust my sail’s.

Semper Paratus