-

Posts

325 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Dillion Brian Grant

-

-

On 4/13/2018 at 1:35 PM, Frosty said:

I'd call that a valid reason! Then move it farther from the house even if I had to make and sell trinkets to pay for materials. A cement board makes a cheap efficient heat shield. it's used to back for tile work in wet or high heat areas. If you use 1/2" spacers to hang it the air space will further protect whatever's behind it.

So wait, to make sure I'm understanding correctly are u saying basically take the cement board and basically attach it to the underpinning on my shelter?

-

Tbh I use it so the heat from the fire doesn't melt the sophet of my shelter lol

-

-

Thar is really cool to be honest

-

I like that well, we have our headstones covered now that's priceless

-

Lol wow all the responses

-

Sounds like a plan

-

Ok that seems like the best idea thanks a lot Thomas

-

Yes it still works but anytime you bend it it just cracks apart

-

Ok so, me and my dad were cleaning one of our buildings other day and I found an old pack of sandpaper, and he said I could have it if I wanted it. The problem is that I guess since it is so old if you bend it(like maybe around 35 or 45 degrees) or fold it it just breaks at the bend and I was wondering is there any way to salvage it and is it worth the time and castle to salvage it?

-

5 minutes ago, Charles R. Stevens said:

Depends on the valume of air they put out and the noise the generate. Those are factors of the fan design it's self, tho paddle and squerlslipery fans tend to be quieter than bladed fans as they turn slower.

I would use a double action bed pump for a JABOD unless you are using hard coal.

Right now I'm using a hairdryer and I'm using homemade charcoal

The Idk what a double action bed pump looks like, any other ideas for other old blowers/pumps that I could repurpose

Noise level isn't an issue for me

-

1 minute ago, ThomasPowers said:

A is amps, MFD is Micro farads; so 2.0 Micro farads is the size of the capacitor.

Ok so then, the smaller one has a smaller capacitor, and less amps but it has higher RPM'S than the bigger blower

So which one is better, the blower is going to be about a foot and a half from the firepit

-

Must be nice

-

Ok so my blower that I have been using for my JABOD forge is sounding like it's gonna die soon so I figure chang it while I can and I was thinking of using a blower from an old Christmas decorations that isn't any good anymore, I have 2 blowers that I can use atm, one is bigger and one is smaller and my question is which should I use?

Here is the list of information for them both

Both of them are 120V, 60Hz, and both are thermally protected

The smaller one has 0.442A written after 60Hz(I know Hz means hertz but what does A mean) and is says that is is 3130RPM and that the Capacitor is 2.0 MFD(What does the 2.0 mean and what does MFD mean)

The bigger blower says 1.58A, it is 2750 RPM, and the Capacitor is 9.0MFD

As always any help is very much appreciated

-

Yup I hate it lol

-

20 hours ago, John in Oly, WA said:

Understand completely. My comment just goes along with that general idea that you can never have too big of a shop. Although, I walk into Home Depot, take a look around and think, "yeah, this could be just about big enough" LOL

nah Id say get 3 home depots, 1 for inside work (grinding, cutting with power tools etc.) 1 for forging and other outside work, and 1 for storage of metal and other such stuff

-

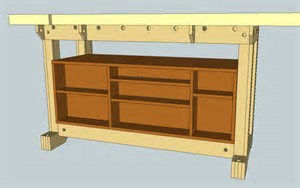

I was thinking if I have the work table setup similar to the way it is in the picture I posted earlier and I could make some sort of door facing/covering, which to be honest the stuff I am intending to store there is stuff that honestly doesn't matter if it is covered in dust lol but are there any ideas for how to limit how much dust ect. gets on the stuff?

-

1 hour ago, genesaika said:

For knifes it might be advantageous to have the sander on a short end. It would give you more space to work. Of course I still can't really say since it depends on what's comfortable to you and your shop.

ok that makes since , im just worried that the curved belt wheel will be hard to get to that way

-

12 minutes ago, genesaika said:

It also depends on what you want to do with it. If you need the bench grinder close to the sander than do that. It's more of a personal choice I'd say.

Put your tools on the table and pretend to use them. Move them about as needed and then once you are happy attach them.

That makes sense, basically I make knives and other things and for the most part the bench grinders will be for working on the spin and such(so I can save on belts) and the sand is for everything else

-

So I guess sander in the center, and a bench grinder on each of the narrow ends? The table is 7' 4 1/2" ×2'

-

22 minutes ago, genesaika said:

The top of my work bench is right around 38 inches. A safe bet would be between 34 and 36 inches. From what I read when looking for a good height for mine you want the top to be about at your wrist height.

I have mine higher because it feels nice and I didn't want to bend over the table too much.

ok thanks a lot Gene, I was assuming the rule of thumb would be about the same as the rule of thumb for anvil height but wanted to make sure

now my other question is this, this table is going to be chiefly just a grinding/sanding table on top and storage underneath(similar to the attached picture) and I wanted to know what would probably be the most efficient way to position my 2 benchgrinders and my 1 belt sander? the table is going to be open all the way around so they can face any direction

-

so I guess my best bet is to base the table height on how high I want the grinders and sanders to be?

-

18 hours ago, swedefiddle said:

Good Morning,

Only "you" can tell what is comfortable to you. Set up an old door at different heights and try it.

Neil

Will do, just didn't know if there was a baseline, like I know how to find the approximate height for an anvil you should be able to stand up straight and be able to hammer without bending your back or arm, I didn't know if the same logic worked for the table or not

-

On 11/24/2017 at 2:27 AM, Frosty said:

While I don't think humidity is an issue for sander belts unless it's excessive condensation IS an issue for other things. Welding rod should be kept in a hot box but other things can be kept safe in an old fridge with a light bulb.

Another old timey trick that works well for things like tool box drawers is anhydrous sheet rock. Sheet rock is largely gypsum and baking it in the kitchen oven above 230 f. will drive out the hygroscopic moisture. Anhydrous Gypsum is VERY hydrophilic and works just like those little gel packs you have to dig out of pill bottles.

It's cheap, easy and very effective for keeping condensation off stuff you want kept dry. Say, keep a 1/2" x 2" x 12" piece under the padding in your rifle case. Hmmm?

Frosty The Lucky.

I really love that idea

JABOD Forge "roof" addition

in JABOD - Just A Box Of Dirt

Posted

Well, the problem for,me issnt the wall, its the ceiling of my shelter,that's what I'm calling the underpinning