-

Posts

325 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Dillion Brian Grant

-

-

Ok so ive got some castable refractory ordered, my question now it this

My forge is 2 parts following the directions on Wayne's website and my dad brought a very good question to my mind which is this, how do I put the ceramic fiber insulation on top

As in I know i put 1 layer of insulation, then the rigidizer, then the castable refractory, my question is this, what do I do to keep the weight of the castable from collapsing the ceramic fiber insulation ??

-

So matrikote can be used on the refractory cement

-

First off sorry for the lauguage really didnt think I said something wrong, but anyways I have finally gotten the money to order everything needed and it is currently on the way the list of stuff I ordered is as follows

1"×24"×25' ceramic fiber insulation rated for 2600 degrees

1/2 gallon of MEECOS Red Devil refractory cement rated at 3000 degrees

1 pint of Matrikote

And 6 Rutland firebricks(hard firebricks rated at 2700 degrees)(the intention is to use them as doors for the front and back

My plan is to use 2 layers of ceramic insulation

Then a thin layer of refractory

My biggest questions are where would I need to put the matrikote

And also how thick does the layer of refractory need to be?

-

First off thanks for agreeing, honestly it amounts to is I want to spend as much money as needed to do it right but i don't want to just me xxxxxxx money away for,stuff that won't work and yes I literally have reread all og them like 5 or 6 times and my brain hates me for,it

-

That is good enough for me then thanks a lot sir

-

When u used the regulator from the turkey fryer, were u able to acheive welding temps easily?

-

Ok, so in summary as long as I get a regulator with a pressure gauge that goes from 0-30 psi is what I need?

-

Ive been reading them and it honestly just confused me more

-

Believe me i want to get started but the issue is I dont know what size propane tank I will need to keep the tank from freezing up and I was told that I needed to know the btus to be able to know the size regulator and the size propane bottle I would need

So basically my biggest question is really just what regulator do I need to use, I want to be able to forge, heat treat, and forge weld fairly easily , sorry for the dumb questions

-

Ok so right now what I'm stuck on is the btu I need to knoq how many btus my forge is going to operate at , there will be 2 burners and the orfice hole that letz the propane into the forge is going to be a 3/64 inch hole ive been doing research but some charts say I will be in the 15000 btu range, and some say in the 115000 btu rangs, and also my regulator pressure will be about 10 or 30 psi

-

First off I love ur design, and yes I think I'm going to use just Wayne's design. This time lol, the next forge will be rocking the t burner tho for sure

-

what do u mean??

Or would I be better judt using ur setup entirely ?

-

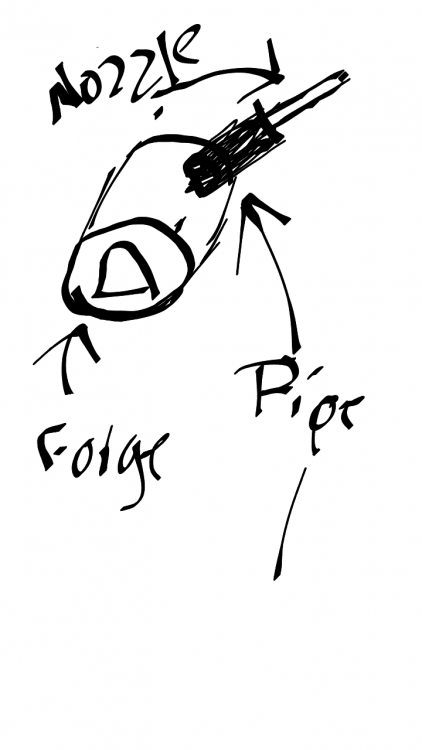

So am I correct in thinking that the t burner would replace the part that the red arrow is pointing at?

-

Ur gonna post a pic? What do u mean if it came out?

-

-

Well then since I'm going to use frostys t burner do u think,my best bet would be to do it like u do it?

-

So, u would just have one pipe welded on, and have ur burner go directly inside?

-

Yes I understand that, my intention was to cut the hole as large as it needed to be then use my dremel to finish the rest of it

-

How am I missing that part?? I understand how,it needs to go,in I just don't understand how,large to,make the hole

-

Anyways currently I have everything makes except the burrner holes this is my setup

I, makes center and it happened to be 2-1/2 inches about where I needed to cut so from the center line I made marks down the bottle 2-1/2 inches off of center, the bottom make is the mark that will be getting cut btw

-

-

Btw any tips, or advice is very much appreciated, I'm intending to use Frosty's t burner design

-

Ok so,I'm going to,be building a forge from a used propane cylinder, amd i decided i wanted to post pics as i do everything,I am going to be building the forge using the steps from the pdf that is on Wayne Coe's website ill be sure to take pictures as often as possible and will be asking for help as needed wish me luck this will be the first propane forge ive ever made

There is one thing I havent been able to figure out yet and that is the holes for,the burners,

In the pdf all it says is this

5. Drill, or cut, a hole in the top (larger part) 2” down vertically from the top and if using one burner

centered front to back. If using two burners put one about 1/3rd back and the other about 2/3rd

back. By making this hole down 2” vertically from the top of the form you will have this hole

positioned so that the burner can enter the fire box at a tangent or level to the floor, causing the

burning gases to swirl within the forge.Now my intention is to do a double,burner and I intend my burner to be 3/4 inches, so how large does the initial hole need to be?

-

4 hours ago, Irondragon Forge & Clay said:

It would be best to start a new thread.

Ok thanks a lot, I thought that would be best bart wanted to,make sure

Propane Bottle Forge Build

in Gas Forges

Posted

Ohhhhh so first the refractory goes on? Ok that makes a lot more sense