-

Posts

325 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Dillion Brian Grant

-

-

5 minutes ago, ThomasPowers said:

Paychecks are one thing; but if you find out that haven't been paying the taxes withheld from your checks---time to FLEE!

Yup definitely time to flee

-

50 minutes ago, JHCC said:

The habit the paychecks had of bouncing occasionally was another. A few months after I left, one of my coworkers had to go to the ER and discovered that the boss hadn't paid the health insurance for six months, so the coverage had lapsed.

Dang that sucks big time

-

It seems like it would be

-

14 hours ago, JHCC said:

When I was working in the art restoration studio, I once had to turn a large-diameter mirror frame on a woefully underpowered and undersized lathe. The only way I was able to do it was to jam a lance-like tool (one that I'd made out of a stonecarver's point, for turning alabaster) into a hole in the faceplate, get the thing spinning with muscle power, turn on the lathe motor, work the frame until the vibration started to get scary, turn off the motor, do some more work on the frame as it coasted down, and repeat. The things we do to put bread on the table.

Once again, it is not necessary to to quote an entire post, especially, immediately following said post.

Yup and wow living life on the edge

-

On 4/22/2018 at 8:29 PM, Frosty said:

Thanks Bob, I'm getting better at realizing when I'm going down that road and turning to happy thoughts. However if I COULD go back 30 years or so I can think of a couple stocks I might drop a few thou on.

Neither have I but I'd like to . . . From a distance.

Frosty The Lucky.

You and me,both frosty, from a distance and possibly with a steel wall with a bullet proof window in between lol

-

Yup I have a drill press, I love that thing to lol that's the thing I love about them is the simplicity of them

-

OK so I spent close to an hour talking,to wayne, btw thanks alot for the advice, anywyas I decided that I'm going to build my own propane forge from an old 20# propane tank, and I'm gonna use frostys t burner design so it is gonna be slow but ill post pics throughout the process thanks for all the help and support everybody

-

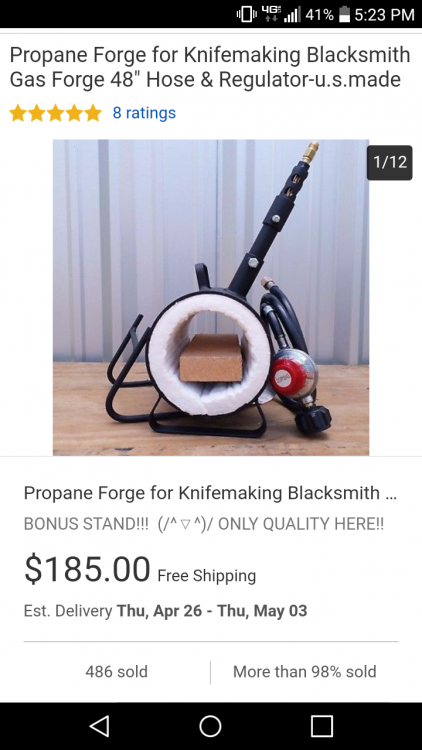

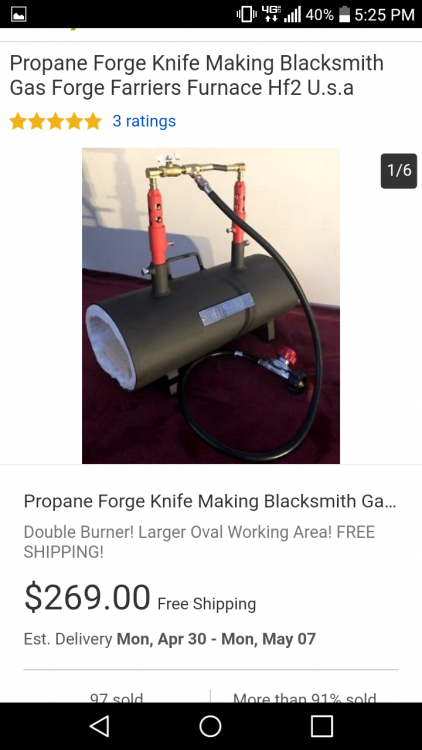

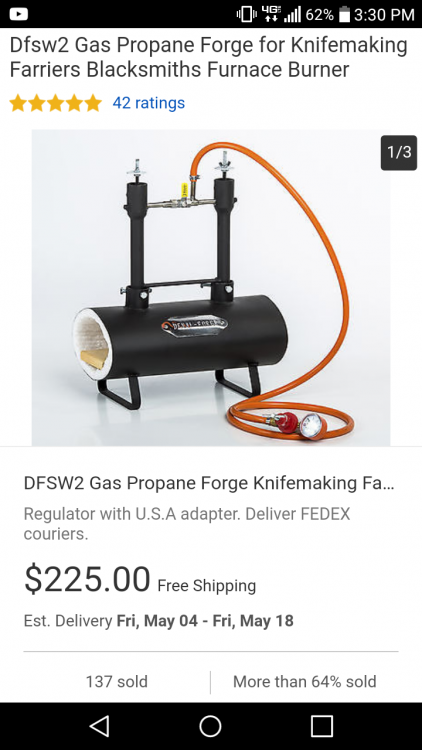

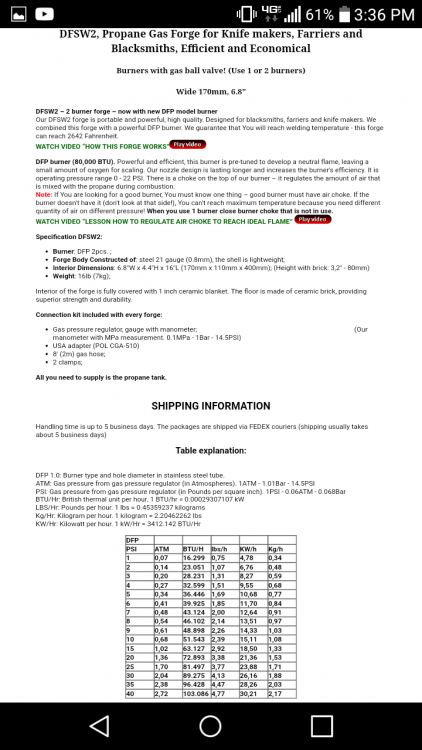

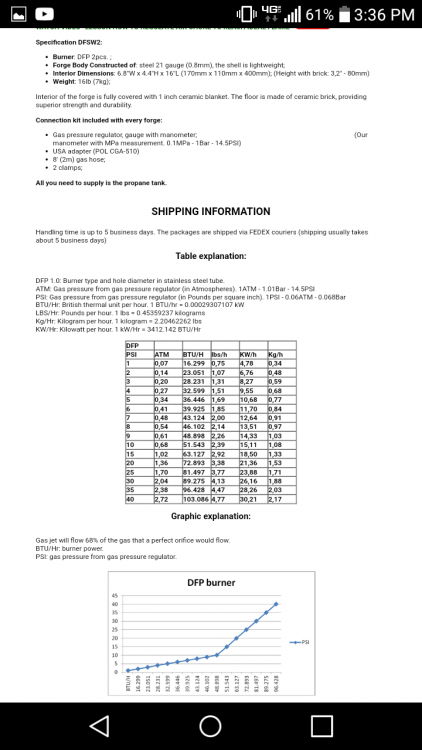

Ok so, if I bout one of those forges and bout some of rigidizer would that be enough? Also how,much would I need if I decided to get the devils forge?

Or,better yet, what exactly wpuld,I need to,get to make it work for me,long term

-

On 4/22/2018 at 8:14 PM, WayneCoeArtistBlacksmith said:

Dillon, check out the Build a Gas Forge attachment on the Forge Supplies page of my web-site. You can get my url and other contact info on my Profile.

I think that we here at IFI have previously discussed these forges. The fire brick is a heat sink, even if the blanket is coated (which it does not appear to be) you will be constantly be repairing the interior. Without a cast interior you will poke holes in the sides almost every time you put metal in or out of the forge. The hose does not appear to be acceptable for Propane.

If your dad would like to talk to me regarding building a forge ask him to call me.

Let me know if I can help you.

Wayne

believe me I want to build,my own the issue is my dad doesn't believe that those forges aren't coated already he thinks they are

-

First off yes I am constantly reading the stuff about the forges on here, and Well how,do u tell of it is coated, because to,me those,forges seem like they are coated

-

-

I realize that it isnt the best, and as far as the doors, my plan is to make some since I'm pretty good at welding, also, how,much does the stuff to,coat it usually cost

-

-

So, ill let you guys know what I come up with, but u said I needed to make my trench wider Charles?

-

Yes I know, I tried explaining that to my dad bout just needing 2 pieces, but he wouldnt listen, he was like it will look bad if u do it like that, I'm just thinking so what, if it gets the job done Thats what matters

-

Yup will do that next time that seems like common sense now rhat I think about it, I will definitely remember that next time

-

What's sad is I guess from it having the same wheel for so long, the nut had gotten way tighter than it normally would be, and I didn't realize it was a left handed thread because after I forced it to stop spinning the nut would turn to tighten but I couldn't loosen it

Finally it came loose tho

-

Well, I mean that my dad said if I was going to do it he was only going to be ok with it if I replaced all of the siding, and all of the ceiling with it, the wall with the siding is approximately 8'×24' and the ceiling is approximately 12'×24' and to fully cover everything it would cost around 500 dollars after taxes

And that is only if I do 1 layer of 1/4" cement board

To be honest I havent ever considered getting it inspected the only things ive done is make sure my mom wont freak out to much about my set up lol

-

Actually yes lol

-

Ok so, I am changing the wheels on one of my 6 inch bench grinders, I was going to replace them with some cloth polishing wheels, anyways, I got one of the wheels off but I am unable to get the nut off of the left side, does anybody have any ideas for how to do this?

Nevermind, sorry for the bother everybody, I finally got it off

-

Ok well, I just looked into it and to shield my shelter like it needs to be done would cost a small fortune so sadly that idea wont be done any time soon

-

Sounds good

-

My roof is about 3-4 feet over the fire

And yeah ive meesed,with a pretty good deal,of sheetrock that stuff is aggravating as can be

-

I'm using a handcrank blower from champion forge that I salvaged, and most of the time yes raw wood, ill post pics of my shelter in a minute

Devil Forge

in Gas Forges

Posted

So I was wondering, seeing how like i said thanks to the help,from wayne the other day I'm going to be making a propane forge using an empty propane tank I was wondering, since I'm intending to post pics of my bottles journey from bottle to forge should I just post them,on here or would it be best for me,to post them in a new topic all together