-

Posts

349 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Zeroclick

-

I made these today in a class. My first hook is on the left and progress to the right it is nice to see the change from the first one. Then in the afternoon we did some twists. On the big onenough I also got to do a forge weld which is my first one and I am quite happy with it.

-

I did a Google search about a bench grinder and a discussion came up on IFI after reading it is joined up and now look at it daily.

-

That just seems a ridiculous idea. Of you want kids to get into smiting they should put on activity days or trial sessions.

-

Show Me Your Hooks!

Zeroclick replied to EJRailRoadTrack's topic in Blacksmithing, General Discussion

Lol that is very true and it is all a learning experience. -

Show Me Your Hooks!

Zeroclick replied to EJRailRoadTrack's topic in Blacksmithing, General Discussion

Yeh it was a clinker I hadn't noticed and put the tine too close and when I pulled out the metal I had lost it all. So just adjusted and so that I now a new hook for the workshop and I will try the heart hook again tomorrow. -

Show Me Your Hooks!

Zeroclick replied to EJRailRoadTrack's topic in Blacksmithing, General Discussion

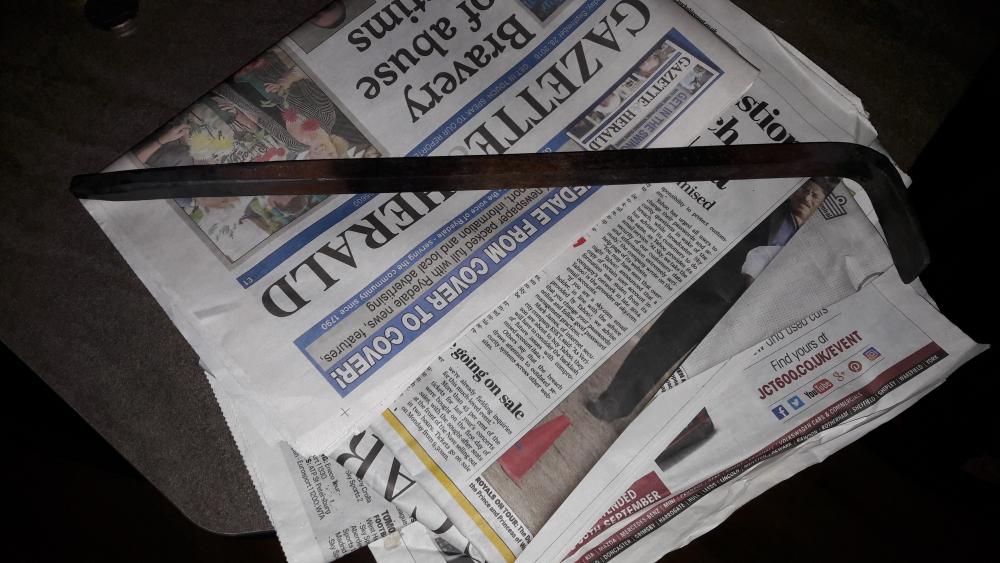

So this is my first ever hook. It is out of 12mm x 15mm, it was meant to have a heart at the top however I managed to burn the heart in the last heat. -

That looks awesome, I love that handle.

-

Really nice shop, can't wait to see what your new setup will be like.

-

Do you know where I can find a , , , ,

Zeroclick replied to Glenn's topic in Blacksmithing, General Discussion

I found this conversation interesting as both a being new to blacksmithing and what may still be considered young (26). I also am a leader at a local scout unit and I have to say that there is a sharp increase in this if you fail then just give up attitude. But that this almost seems to depend on the parents as there seems to be this attitude of you can't be harsh with my little cherub that a lot of parents seem to have, as I tell my scouts if you push yourself and achieve something that you failed at to begin with then you will always be proud of it. In terms of blacksmithing locally in the paper there was a position for two apprentices and they could not get anyone, when asked local people said it was to much hard work and to me that just speaks volumes on the values of young people. -

A good turn. I will probably try working round it and work the paint off then get a better look at the face. The edges are pretty rounded, but I am not sure if they need a little more. I want to avoid taking a grinder to it if I can.

-

This picture shows the chip. I am hoping that doing the radius will reduce it further. But I am so happy with it either way. It was smoggy that gave me the heads up and I really owe him one.

-

My new anvil I just bought. It is a Brooks 141 lb, not sure about the age maybe someone will know. It has one chip about the size of my thumb. but nothing else and is a level as a snooker table. also got all the tools shown and a post vice.

-

I have seen these for sale

Zeroclick replied to Zeroclick's topic in Anvils, Swage Blocks, and Mandrels

Well it turned out to be even better, he is the design and technology teacher at the local school and said he will give me all the scrap steel from he school and off his farm for free which is a real win. The sand is a mixture of hand and weed killer it's to be brushed into the block paving. For my forge I used soil to line and it is working well so far. -

I have seen these for sale

Zeroclick replied to Zeroclick's topic in Anvils, Swage Blocks, and Mandrels

I think I have found a good stump in the woods near my house just have to pick it up. It will need a plinth as it currently sits at knee height. I was thinking of mounting the vice to some 4x4 that I have and then mounting that to the ground. I was going to watch Andy McKenzie's video on vice restoration thought it would be a good starting point to get it back in full order. The sand is just anti weed sand that as you can see by the photos I really need to get used. -

I have seen these for sale

Zeroclick replied to Zeroclick's topic in Anvils, Swage Blocks, and Mandrels

-

I have seen these for sale

Zeroclick replied to Zeroclick's topic in Anvils, Swage Blocks, and Mandrels

I think that's what they call fate I am definitely getting it. I will call him tomorrow morning and pick it up. The guy said his granddad got it for the farm and it has only been used a handful of times. which you can really see by its condition. -

I have seen these for sale

Zeroclick replied to Zeroclick's topic in Anvils, Swage Blocks, and Mandrels

Hi, I went down and looked at the Brooks and it was in really mint condition and performed well in the tests. It turns out he has three post vice's and will include one with all the other stuff. Thanks for the heads up it couldn't be more ideal. -

I have seen these for sale

Zeroclick replied to Zeroclick's topic in Anvils, Swage Blocks, and Mandrels

I think I will contact him this afternoon and maybe pop down tomorrow and do the rebound test and weigh it. If it does show itself to be really decent then I might take a gamble. -

I have seen these for sale

Zeroclick replied to Zeroclick's topic in Anvils, Swage Blocks, and Mandrels

That seem's fair enough, I really don't think I need the swage block yet as I am really just getting started. It was just with this one only being 15 mins away I thought the condition looked good, without having done a rebound test. But I think I will hold off for a bigger anvil when the right one comes up. Thanks for the advice. -

I have just seen both of these for sale the price is £400 for the pair or £200 each. Just hoping for some advice I have no details about weight.

-

I did think that but just with the warning on the video, I am forging under the open sky at the moment so ventilation is my main advantage. Thank you for the reply.

-

Hi All, Sorry if this is a stupid I just want to check something, if when I am using my coal forge I get small blue flames within the fire. Do I need to be concerned that I am burning harmful chemicals, I have always previously thought that blue flames just indicated a hotter flame. But I watched a video on youtube about harmful gases when heating metals and it mentioned a key indicator is a blue flame. Thanks,

-

Thank you I am really happy.

-

-

Advice on an anvil design

Zeroclick replied to Zeroclick's topic in Anvils, Swage Blocks, and Mandrels

I have had my first go with my new forge and anvil. They both worked really well. Thank you for all the advice I am definitely hooked now.