BeaverNZ

-

Posts

353 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by BeaverNZ

-

-

If budget is a proplem have you looked at a rolling mill they could be made for a small amount with some talented scrounging and from what I have seen of them they work very well

-

Looks like you are already mostly done, follow the manufactures recomendations and dont scimp on concrete volume Cheers Beaver

-

-

Are those wire rope handles on the bench for tooling I had wondered about doing some thing like that myself as it would be a good way of lessening any shock from miss hits

-

-

I have a Wilkinson and I see mostly Peter Wright and Wilkinsons here in the lower south island of New Zealand

-

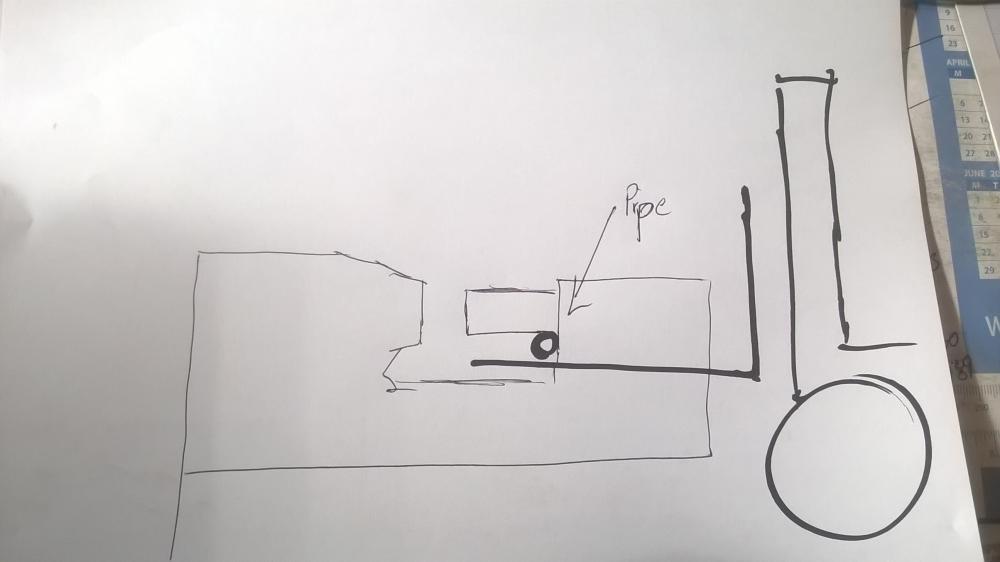

What Robs said is a valid point If I was doing this and had access to a forklift I would try to lift it back up as shown in my scrible this is lifting close to the load centre mass and care would have to be taken when the load tips foward that the pipe doesnt roll forward and you drop the load, Lifting like this also gives you a low lift. Just be carefull take your time and think about out comes before you get commited and past any possible point of no return Cheers Beaver

-

When I was doing my power hammer instal I had a quote for mat by Tico anti vibration pad part number MGTP2500. These were quite expensive as well and they were 300x300mm sq and $266 NZD each and needed six of them, I didnt end up using that and used wooden blocks instead. Cheers Beaver

-

-

8 hours ago, Charles R. Stevens said:

Marketing is a problem. Their is a big difrence in the peak horsepower an electric motor can produce at start up, horsepower it can produce hours on end and horsepower it can produce just before the magic smoke starts leaking out. The big motor you own and the ones you will buy are rated for continues service wile the add men clame what ever they want realy.

Some one years ago jokingly told me that its not electricity that makes things go its smoke, and when a motor won"t go anymore its because the smoke has leaked out and you have to take the motor back to an electrical service place and get it filled up with smoke again. Black smoke is more expensive than grey smoke. Electric lights are actually dark suckers and the dark comes out of your toaster and makes your toast dark and the excess dark comes out of the power station chimneys. Electricty is just a way the man takes your money off you ITS A CONSPIROUSY LOL cheers Beaver

-

Nice, I like the look of both them simple and clean lines Cheers Beaver

-

Since you have a hole in the back now you could put a grease nipple or zerk as you guys call them and hydrulic out it with a grease gun most lever type grease guns will develope up to 10000 psi. I also agree with Frosty but you have to heat the female part quickly or they both expand if they both heat at the rate Cheers Beaver

-

The pump just wont develop the design pressure and the smoke will quickly all leak out of the motor and it wont go any more

-

Wow Im going to try coffe if it makes the colours pop loike that, Beutifull blade by the way Cheers Beaver

-

I like that alot it looks like an Xray

-

The problem you will have is the ram you have because of its lower design pressure to get the same tonnage it will have a larger bore which means it has a greater displacement so it will be slow. That pump because of its high design pressure and lower flow output is intended to work smaller dia rams which have a smaller displacement but because of the high pressure still will have a good speed AND tonnage. The trick with hydraulics is to have matched components, You need a ram designed for the pump to get good performance otherwise it will be a compromise. Because the rams design pressure is about one third of the pressure to get the same tonnage a matched high pressure ram could produce it will need three times the piston area with means three times the displacement which means one third of the speed a matched system would have. DONOT TRY 10000psi in the ram Cheers Beaver

-

Very nicely finished Congrats Cheers Beaver

-

Frosty

Thankyou very much for compressing all that great info into one area there are several things that you have enlightened me in that I have been trying to find about ridgidiser use and when to cut the burner ports now i have some specifics I will finish my gas bottle forge. Cheers Beaver

-

Hello Thomas

Hmmm I thought someone might say freehand and thats probably what will happen and my officail work title is a fitter welder A so i have a foot in each camp welding and machining and now Im doing my best to add forging which is a lot different in how you think about how to make things, Volume instead of size. I think it may be time to bite the bullet and make my smaller variable speed linisher that I have been thinking about for ages Cheers Beaver

-

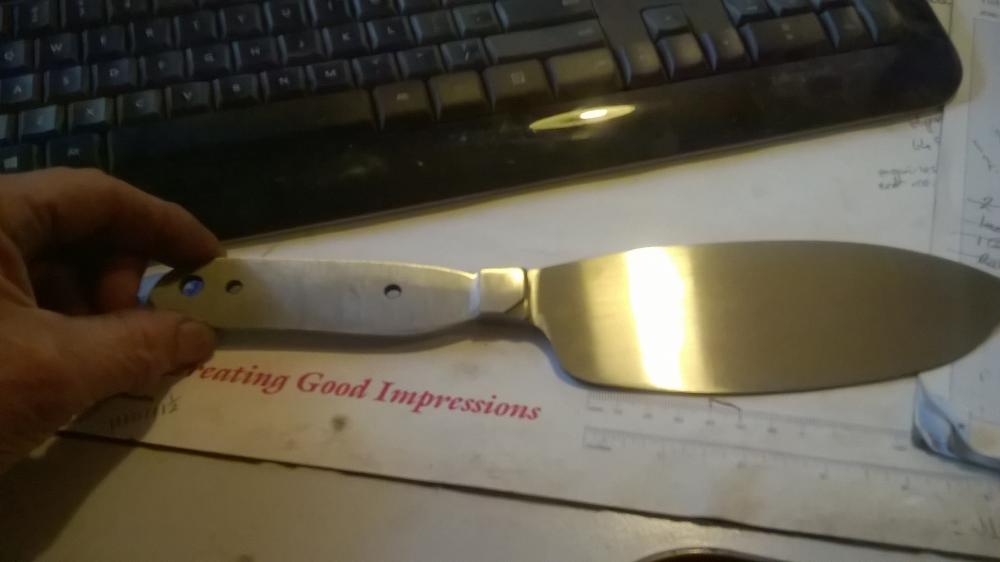

I am at the point of the final finishing of my blade and I am torn which way to put the edge on my blade, its all heat treated and almost as polished as its going to get before etching but I am wondering on how to stop the distal taper from affecting the width of the bevel. All the beveling that i have seen on youtube have been quite thick blades and parallal my blade at the thickest where the bevel will start is about 2.6mm down to about 0.9mm at the point. If I use a diamond imbeded flat cutter and a Heim/rose joint set at the correct height and point or maybe one of those little finger belt sandes/power files guided by the same means I have alot of time in this now and dont want to stuff it any suggestions would be good thanks Beaver

-

With hydrualic presses when the press is loaded up with pressure and released there is a spike of very high flow and pressure thats what would of burst the hose you had at the start. The flow may be well over 100 lt min just for a split second. Pressurised oil from a burst hose/pipe is exremely dangerous as you and others have said, when I had bulit my press I was setting the relief valve and the steel pipe blew out of the base of the ram it made a very big bang gave me a hell of a fright it was at about 3000psi. I thought it was my fault by not tightening the fitting correctly so I redid that fitting and checked all the others then cotinued and got to just over 4000psi and the same fitting came apart. There was an explosion this time the pipe wrapped itself around the oil tank, filled the workshop with oil mist and i had lost all faith in the fittings but it turned out that the hydrualics place had steel pipe that was hard and the fittings couldnt imbed into the pipe to get the proper grip .The hydraulic supplier let me use their test bed to pressure test all the fittings after that which helped restore my confidence a bit The fittings I used were aeroquip and they normally never ever do what happened to me I have covered all the fittings with steel guards just incase it happens again as some are head height. The max pressure with my press is 4300 psi with an 8" dia ram Cheers Beaver

-

47 minutes ago, bubba682 said:

Its the only way to go Beaver when i weld mine ill be goin over it with stick 7018 a1 with a little preheat just enough to sweat out the moisture.

The Low hydrogen rod run correctly would be just as effective and alot faster as the tig weld but thats up to you, The mosture that you see when preheating is just water condensing from the flame fuel gas hydrocarbons burning and turned into water and Co2

-

Nice not too many people have a partly tig welded press frame

-

I believe from others coments that speed may be as important as tonnage see if you can find the max pressure it will develope as an example a 4" ram at 3000psi will develope 16.8 tons if I remember correctly read through what others have put my shop press has 100 tons but is a bit slow and I used to loose alot of heat to the tooling from my work Cheers Beaver

Simple Oil forge Build

in Induction Heating, Oil forges, etc

Posted

While I wont go into how you heat the zinc this is how I would cast it after making sure the mould was properly heated before pouring in the metal. There is probably already stainless steel bolts welded where an anode has been in the past and this stops damaging the paint and antifouling of your hull if not you should fit some. Just be mindfull that too many anodes can be as bad as none as you have to have a ballance because you are basicly making a battery. The holes in the stainless strap in the centre are to increase the keying of the zinc and stop it coming loose and the strap just rests on top of the channel and the zinc will be held slightly off the surface of the hull Cheers Beaver