-

Posts

69 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Zyphiza

-

- 4 comments

-

-

-

If it was used for a kiln it may not stand up to forge heat most bricks are rated to a certain heat, this is what a dealer told me when I contacted them

-

Did I over pay for my anvil?

Zyphiza replied to Zyphiza's topic in Anvils, Swage Blocks, and Mandrels

So I took your advise though it wasn't the first thing I forged, this is what I made him it's my first try at something like this but I think it turned out alright -

Oh yeah oops..... shows what I get for staying up to about mid night all the time.... making myself look stupid... Don't worry the torch marks stay I've been working around them so far, and I don't plan on doing something like ruining the hardness by welding,grinding, or the worst of them all milling it. I was cringing as I typed this thinking about it happen...

-

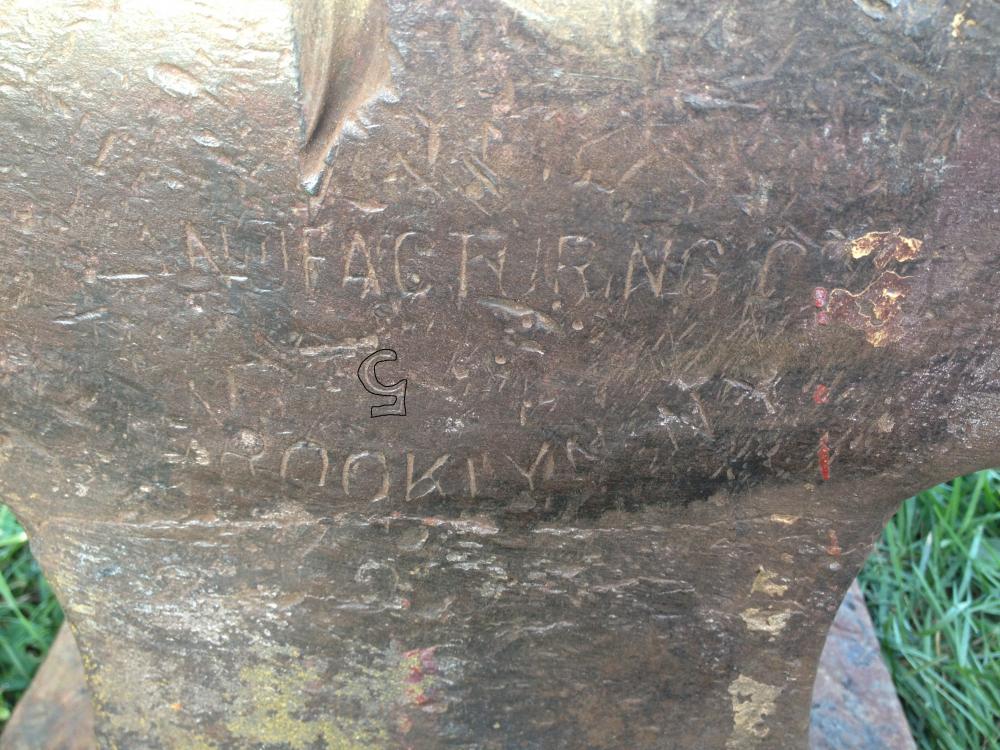

Yeah I'd say, I guess the scrap guy was holding onto it until someone came into ask for one that someone was me, I got a great deal on it though considering I got it for 275, And as my first anvil I couldn't be happier. So far it's helped me make my first two pairs of tongs Also in case anyone happens to be interested It's been dated to 1910, so that makes it 115 year old which is super cool

-

This is my anvil around 300lbs Hay Budden I got from a scrapyard Cleaned it up now, probably going to make a metal stand with angle iron and tube steel fill with saw dust and oil then add a rubber base to it to kill the ring. In the background you can see the piece of rail road track I started with, smaller one was used for a flat face and edges

-

So I finally got around to using my new anvil only been blacksmithing for maybe 3 months off and on due to having problems with getting fuel but more to the point I finally got a well needed tool my first pair of tongs Wish i had some video to go along with the pictures but sadly I don't. Give me your opinions. These we're made from memory only I did not use pictures, references

-

Thank you for the source on fire pots and over all if anyone has an idea judging from both projects what does someone think would cost more to make the gas or the coal forge Thanks.

-

Hello I'm posting here because I would like to make a more permanent forge. I'm currently using a brake drum lawnmower forge and would like to make something I can use in my building during the winter months below you will see pictures of my shop and the forge designs I like most. this is a link to the coal forge I was interested in https://www.youtube.com/watch?v=Bn1qbC3EbPM this is a link to the propane forge and a link to the burner I would be making with the help of a gas fitter. http://www.zoellerforge.com/simplegasforge.html http://www.instructables.com/id/how-to-build-a-gas-forge-burner/?ALLSTEPS Also if gas is very expensive I would like to know due to the fact I have not used it for forging nor do i know how long a 20-100lb tank would last me. If someone has experience with gas forges and knows roughly how long the tanks should last me I would appreciate this very much. Thank you to anyone that replies. These are the photos of my shop. . If anyone knows of a source where I can get an actual firepot that would be a great help or something that I could use other then a brake drum

-

Did I over pay for my anvil?

Zyphiza replied to Zyphiza's topic in Anvils, Swage Blocks, and Mandrels

Thank you everyone for the help I'd like to try a silicone base and I might get some chain big enough I had some in my shop but it was a bit too small sadly, my next project is a propane forge (: -

Did I over pay for my anvil?

Zyphiza replied to Zyphiza's topic in Anvils, Swage Blocks, and Mandrels

Okay thank you I believe I should have one around my shop -

Did I over pay for my anvil?

Zyphiza replied to Zyphiza's topic in Anvils, Swage Blocks, and Mandrels

This is what I'm putting it on for now (: Yeah I saw somewhere that a chain would work ideally how long should it be? Again thank you for the suggestions -

Did I over pay for my anvil?

Zyphiza replied to Zyphiza's topic in Anvils, Swage Blocks, and Mandrels

Okay thank you guys I'll just hand brush it and remove what I can paint wise, I suppose it being a 115 years old I would remove a lot of the character with just something as simple as a brush, thinking about it I want to keep it how it is I like the look of it lol, I have it set on a stand now and that was not easy, I played around a little bit with a small piece of steel (don't worry it wasn't cold) today to see the difference between that and the piece of railroad track I was using... Literally worlds apart it's so much easier to use and with the weight of it I don't really need anything to anchor it to the stand which rocks because that track bounced around quite a bit even though I drove it into a stump with railroad ties. also did a bit of looking around because the ring was quite loud, my shop is about 100 yards from my house and they could hear it still, I put a large U bolt in the pritchel hole it seems to help with the ring -

Did I over pay for my anvil?

Zyphiza replied to Zyphiza's topic in Anvils, Swage Blocks, and Mandrels

Hey first of all i would like to thank everyone for their help I have learned a lot about my anvil in the last day, I appreciate it so much I'm so happy and lucky to know what I do. And I won't do any grinding or welding or "fixing" to it with my limited experience I just wasn't sure if the edges were okay or not, now I know they're fine so I'll just do my best to work around the torching marks, I'm more then happy to listen because after doing a bit of research I really am lucky to get a H-B anvil this size for the price I did and I don't want to do anything to damage or ruin the anvil because I hope to keep it and not replace it. Also I'm curious if a wire brush cup attachment for an angle grinder is fine to use to clean it up? I've used them to clean steel before I just wanted to double check, and thank you for the recommendation of linseed oil I'm going to do that as soon as possible I wasn't really sure what to use to prevent it from rusting now I know If anyone know of an easier way to clean it up I'm open to suggestions, thank you very much -

Did I over pay for my anvil?

Zyphiza replied to Zyphiza's topic in Anvils, Swage Blocks, and Mandrels

Also curious, I'm thinking about maybe fixing all the torch marks and fixing the edges, I know this has to be done with tool steel welding rod and pre-heating the metal before welding, would this destroy the hardening of the steel? would I have to re quench it because if so that's a job a bit larger then what I can handle. Thank you. -

Did I over pay for my anvil?

Zyphiza replied to Zyphiza's topic in Anvils, Swage Blocks, and Mandrels

-

Did I over pay for my anvil?

Zyphiza replied to Zyphiza's topic in Anvils, Swage Blocks, and Mandrels

I see a 2 and what looks to be an 8 or a 9 after that the last number is completely gone so that means I have a 280 or a 290 pound anvil? that's awesome -

Did I over pay for my anvil?

Zyphiza replied to Zyphiza's topic in Anvils, Swage Blocks, and Mandrels

Yeah true, that's a good idea I didn't really think about it but I might make him a key chain or something -

Did I over pay for my anvil?

Zyphiza replied to Zyphiza's topic in Anvils, Swage Blocks, and Mandrels

okay aweosme thank you so much guys i really appreciate it