-

Posts

640 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Forging Carver

-

what's a texturing hammer? that's sounds cool. So you basically have 2 leaves connected by a stem then you cut it in half? Any pics of the finished keychain? Thanks yeah I can do the taper part for sure. The main difficulty I have is that I use 1/2in and it takes me a while to work the stem to around 1/8. Also it seems I loose heat very quickly cause when I work on flattening the taper it takes me a few heats. I see guys like Brazeal on the internet who can forge the entire leaf in like 3 heats. I know that he is VERY more experienced than I am but his steel stays hot a lot longer than mine and can be made in only a few heats. Thanks

-

Yeah I meant no trouble, just like what cliffart said it is hard to put in words that don't sound cruel. What i mean is that you can always ask Steve in the chat when he comes on around 6-7 pm eastern time or pm him, but he posted some info of his book on site and my guess is that that is a basic sneak peak and if you need or want more detail then he probobly thought that is what the book could provide. I don't want to put words in his mouth and I am sure he wouldn't mind sharing a bit like he does with all of us. This is very hard to write without getting words mixed up sounding different or speaking for Steve, but I tried my best and don't mean any harm or troubles. Remember one thing, "the only source of knowledge is experience" Hope this helps

-

Those are only two pics I tried to put the video but it wouldn't load. I I'll try again, and just buy some more steel and see what happens. Dale told me a project I could do that starts from a 2' 3/4" bar and turns into a 4' 1/4" bar. This will hopefully get me quicker at moving the steel. I'm gonna buy some more steel at the hardware store too. What size steel do you guys make for keychain leaves, and about how large do you make the stem? Thanks

-

well I'm not Steve, but I think that he wouldn't want everyone telling what is in his book cause then he won't make any money.mi have the book so I will ask for permission to tell you all.

-

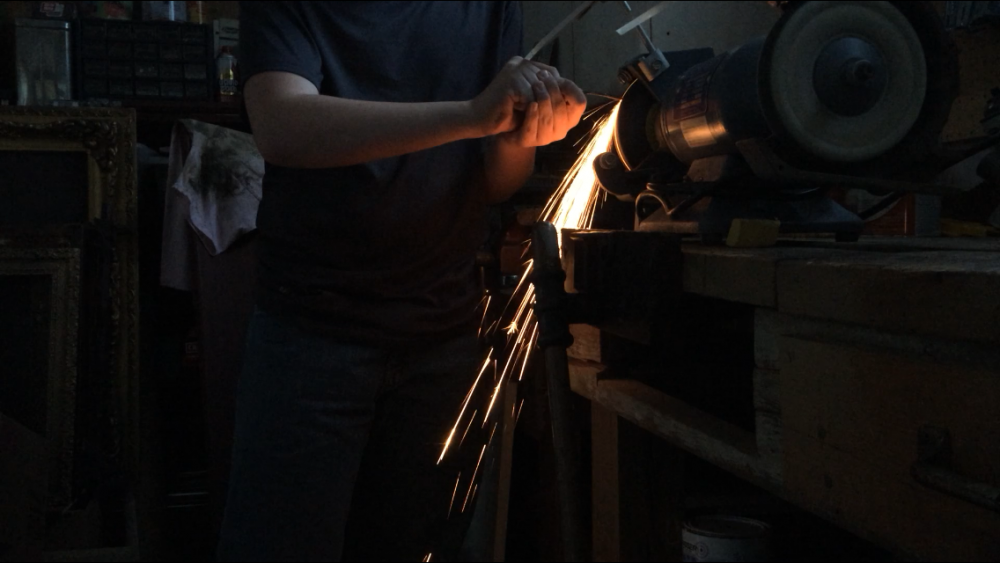

I started making leaves when I realized they take me a very long time to make. They take around 4 hours with me using a 3 pound sledge on 1/2in steel. I am using steel I got from my uncle, so I was told it might be high carbon. I did a spark test and I do not think it is HC. I will show the video below. It takes me a while to move the steel for some reason. Any suggestions besides me showing a video of me forging a leaf? Thanks Vid of the spark test won't work here's some pics: Damaged Video removed

-

thanks for the help.

-

not a problem. Yeah now that you mention it antler will get hung up. I guess it comes down to first kind of coal and second kind of cool; those of you who watch nutnfancy know what I'm talking about. Glad I could help.

-

Hot cut

Forging Carver replied to Forging Carver's topic in Hot Cuts, Anvil devils, metal cutting on the anvil.

Never mind. Just saw the video and it answered my question. Thanks for the help -

Hot cut

Forging Carver replied to Forging Carver's topic in Hot Cuts, Anvil devils, metal cutting on the anvil.

I am using a 3 pound sledge hammer to make the general shape, and I have a 2 pound cross pein I was gonna use for the fan shape. How do I heat the center part of the hot cut? I tried everything from water and positioning in the brake drum. Also, what part do I heat; the shank or bottom of the what will be chisel? Thanks -

You can make a frame handle with the thin wood like what cliffart said. Also, you can buy antler of of ebay cheap and a curved tine would look really cool for an edc. I have an old tine I used when I tried to flintknap which I got of a flintknapping website for $2. Not my knife its yours, so these are only suggestions. Hope this helps

-

Hot cut

Forging Carver replied to Forging Carver's topic in Hot Cuts, Anvil devils, metal cutting on the anvil.

I used 1 inch steel. How do I make the shoulder? Once the shoulder is done then I have to make the top square and i should be good to flaten and spread? Once the fishmounthing is addressed, do you think it will be too big to make the cutting edge an should i cut it shorter? Thanks -

I am not a pro smith, but I do love and collect knives. The knife came out so nice i would use a nicer wood than hickory. I would go with maple, desert ironwood, bone, or antler. Plain hickory is too plain for me because it doesn't make your knife as special. Hope this helps.

-

I started to make a hot it today since my other one got stuck in the hardy whenever I used it. I plan on making it a brazenly style hot cut, but make it have a shoulder. I think I made the taper fine, then I cut the rest of the steel I do t need on the top and started to heat that and got it to form the shoulder. It got a little bent out of shape, but I think I should be able to fix it. My question is that is the shoulder I have on it big enough to stop the shank from going any further into the hardy, and if it is large enough to not chip. Also any tips on how to make the fan shape hot cut. I know that I need to fuller it, and I hope my 2 pound cross peen will do the trick. Am I headed in the right direction? Thanks

-

i was making a hot cut today and needed once I finished the hardy shank I had to wait for my dad to come home so he could use the angle grinder and trim the steel so that I could make a shoulder then the cutting part. In the mean time I started my second leaf. I knew from the beginning I messed up the taper but I continued on. Now it is almost finished, but the lead is shaped oddly. Should I discard it is there something I can do to fix it. The stem is off center too. And the left side is thicker than the other. Thanks

-

Show me your Bottle Openers!

Forging Carver replied to Arbalist's topic in Blacksmithing, General Discussion

thanks for the help -

Show me your Bottle Openers!

Forging Carver replied to Arbalist's topic in Blacksmithing, General Discussion

My trewax came with a soft foam sponge. I am not sure if it is to absorb moisture or not? I used it on my first leaf, not sure if it looks like your wax. My mom loves it by the way, so I gave it to her and she has hanging on the old flintlock on our fireplace. Not to change the subject but I heard that Alaska is very nice. I have always been interested in Alaska because I love fishing, kayaking, and the outdoors. I heard there are lots of bears, and bears are my favorite! I hope to visit eventually when I am 18 and if I do go I will tell you and maybe I can learn a bit from you. Do the guys try to preserve the land up there and stop too much building on the land? Thanks -

Show me your Bottle Openers!

Forging Carver replied to Arbalist's topic in Blacksmithing, General Discussion

do you keep the application rag under or above the sponge that comes with it? -

Show me your Bottle Openers!

Forging Carver replied to Arbalist's topic in Blacksmithing, General Discussion

how do you know when the steel is around 160f? thanks -

Show me your Bottle Openers!

Forging Carver replied to Arbalist's topic in Blacksmithing, General Discussion

Thanks for the great ideas. And nice Rams openers! -

Show me your Bottle Openers!

Forging Carver replied to Arbalist's topic in Blacksmithing, General Discussion

I was thinking about getting a full sized halligan bar and making the poker end into a bottle opener but I am not sure where to get a used one since they last forever. -

Show me your Bottle Openers!

Forging Carver replied to Arbalist's topic in Blacksmithing, General Discussion

love the ideas thanks! haligan bar seems a great idea, as does the fire hydrant. Or maybe a helmet with the badge on it and opener where your head will go (miny helmet). Thanks! -

Show me your Bottle Openers!

Forging Carver replied to Arbalist's topic in Blacksmithing, General Discussion

I was thinking about making a bottle opener for the fire dept that my brother, dad, and eventually hopefully I am at. I was thinking about a wall hanger, and maybe putting co.3 on it or their badge. Any ideas on how to do that? Thanks This is their badge: -

Show me your Bottle Openers!

Forging Carver replied to Arbalist's topic in Blacksmithing, General Discussion

ok thanks i will give it a go! -

Show me your Bottle Openers!

Forging Carver replied to Arbalist's topic in Blacksmithing, General Discussion

this a good begginer project? And do you think I can get away with using vise grips or a pair of flat jaws?