-

Posts

1,056 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Gergely

-

What did you do in the shop today?

Gergely replied to Mark Ling's topic in Blacksmithing, General Discussion

I usually do both things you mentioned. Right now my slack tube is winterized (upside down) so I use a bucket that had pretty warm black water in it. I put my hand on the other anvil's face to cool it. After the early morning session I realized I'm too tired to continue so I went to sleep a couple hours, but some costumers woke me up after 40 mins. when they left it was too late to go back and rest so I started to work. Not long though... But enough of me whining. I have forged today from the morning, hand's a bit tense but works. Luckily I managed to save the war hammer! Bests: Gergely -

And don't forget to neutralize the acid after the soak. Also put on some sealing finish right after the neutralisation (clear enamel for example).

-

What did you do in the shop today?

Gergely replied to Mark Ling's topic in Blacksmithing, General Discussion

Ouch! That sounds nasty! Hope you're better now. You hit the nail right in the head, Das: I was making a war hammer from a regular scrapped cross peen. It went really smooth and fast when I just decided to "costumize" the eye. I srewed up all my work - have to throw out the hammer head. AND while correcting the eye I burnt my HAMMER HAND with the eye punch, which was left backwards on the anvil. Why on earth was that tool backwards and why was I grabbing it with my hammer hand?? - That's where the tire factor comes in. Tried to go on as I had much work undone, but 20 mins of trying was enough. (Note: if I grab it with the tong hand it does no harm, I wear glove and that hand feels not that much anymore.) Anyways it's better now, I go and try to work - mainly cleaning and finishing. Maybe some nail hooks if I have the time Bests: Gergely -

What did you do in the shop today?

Gergely replied to Mark Ling's topic in Blacksmithing, General Discussion

Burnt the heck out of my hammer hand, so let's call it a day! Hopefully tomorrow I can work again, cause Sunday is craft fair day, One more check sign in the "don't forge when you're too tired" list. Bests: Gergely -

I really like it, Aus! Funny and angry

-

What did you do in the shop today?

Gergely replied to Mark Ling's topic in Blacksmithing, General Discussion

Thank you and thank you! Oh, my!! If I could come up with something this simple I shouldn't have to spend four hours to make one piece for the same function! Okay this supposed to be a joke, but I really like this and if you don't mind I steal adapt it to my purposes. Bests Gergely -

What did you do in the shop today?

Gergely replied to Mark Ling's topic in Blacksmithing, General Discussion

Now I have to look around on the German used book sites, thank you. Some things came out of the fire yesterday: Wall mounted poker holder for wood stove: Starting stock and result: And two pokers, no finish yet: And I still havent finished the Brazeal tongs, but I use them anyways. They work great! Bests to All, keep the resistance alive! G -

Thank you, Gentlemen! I feel for you, Das, anvil envy is a real bittersweet joy of life. Having this 440+ lbs/200+ kg anvil has its advantages. But besides it's being a fantastic workhorse, one of my favorite things about it is the psychological effect it causes. When people (usually older men) watch me at fairs/demos forging on my 114 lbs/52kg travel anvil and they say: "I have a much larger anvil at home". Or: "you can do much better job on a larger anvil". Instead of defending my small anvil's qualities I just nod along and say: Yes, you're right, that's why I use a 200kg anvil in my shop. Conversation usually stops there as most of them wants only to argue... True, but it's not the anvil that's imaginary I'm really happy to hear that, Aus! I've got so many ideas from you, at least I can reciprocate a bit. One technical thing: I made the rivet from square stock. The holes are square, too. Does anyone know about any negative side effects when using square rivets? Bests: Gergely

-

I did it, bring this out of my head today. Quite robust one I can say. 1 3/4" x 3/8" flat old iron tire stock, hot riveted together. Carnauba/beewax mix finish - first try with that. And the original stock in front of the 3'/1m long anvil:

-

What did you do in the shop today?

Gergely replied to Mark Ling's topic in Blacksmithing, General Discussion

Well, LittleB you created a very valid thread, didn't you? This was really good idea. Good work, very nice mini hammer - now you can tame the mouses to forge, maybe get them a Mousehole, too. Bests: Gergely -

Thanks, Guys! Yeah it's stable - but just for sure's sake I go and buy an other bottle I have a different concept in my mind, hope I can show you by the evening. And it came as a surprise to me that the neck of wine bottles around here are 30mm/1 1/4" dia. That's exactly the same as my beer bottle opener holes. Mysterious, isn't it?

-

What did you do in the shop today?

Gergely replied to Mark Ling's topic in Blacksmithing, General Discussion

Wow, Das! Glad to hear! Almost finished the Brian Brazeal's ultimate tongs. The ends of the reins are undone, and it needs some fine adjusting and hard testing. A half round anvil stake came out, too. It's from an old machine part that already had the half round, so I cheated mostly -

I've been following this topic from the beginning, and you guys put the flea in my ear. I had to make this, and I think it was inspired by Donniev's work But thank you all for this cool thread. It isn't finished yet only out of the forge state.

-

You got the essence pretty good!

-

Well I found them because I try to make a pair like that. If I will succeed making it I'll post my picts. But it will be different even though I try to follow this guide. My skills are nowhere near Brian's and my tong stock is 1"x3/8" (25x10mm) steel. Bests: Gergely

-

It's not mine. It's Brian's photos and work. IIRC in the first page of this thread you can find Brian's comment about these tongs, I just re-loaded the missing pictures because I found them on my PC. Bests: Gergely

-

-

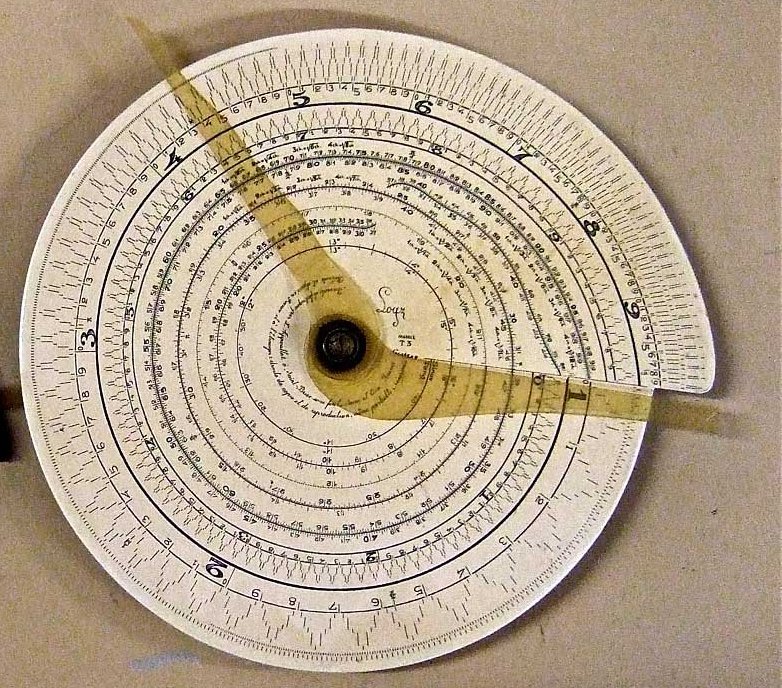

my google doesn't provide useful info with the same search terms Just found out though: breveté means patented in French. Anyways you might hit the nail on the head with it's being a slide rule. There are circular slide rules but those have concentric circles on them. Spiral slide rules look like this one, although they are a bit different, too. Like this:

-

What did you do in the shop today?

Gergely replied to Mark Ling's topic in Blacksmithing, General Discussion

Small pair of tongs for 3/8 - 3/4" or 8-20mm square stock. Not everything went as I wanted but all in all I'm happy with it. It works all right. Second pict shows it after testing under PH with a 20x20mm square piece. Bests: Gergely -

It's really interesting: the different types of numberings are not in linear correlation with each other: 315=8 (315/8=39,375) but 485=23 (485/23=21,09). I think this means it can't show length units or at least not both of the numberings. And the scaling with the single digit numbers - it goes from 1 to 8 but still it contains 11 fields I'm really curious what this can be... Google helped me not. Bests: Gergely

-

Forging D3 / 1.2080 tool steel

Gergely replied to Gergely's topic in Blacksmithing, General Discussion

Yes, they do. Right now I can't remember that before or after the forging or both times. So, after I educated myself a bit on this matter (how to get a self-ironic smiley) I gave it a try. Just for fun - as I said earlier. The experience I learned was very edifying (if I use the correct word): stop being an idiot and don't fool around with stuff you can't use properly othervise you're just wasting time and money. As for the fun part: this stuff has over 2% Carbon and 12% Chromium in it. Even under power hammer (66lbs/30kg springhammer) it was PITA to forge. When it was at its "right" forging temperature (hopefully) it moved all right. But after 20 seconds it cooled down, stopped moving and anyways it should have to be put back to the fire. After circa 111 heats I made this punch, I intend to (not) use as a hot punch. I cleaned it up a bit to remove the rough forged surface, that I usually don't need to do when I make this sort of tooling. It has some cracks near the striking end, so it was really worth the effort . I only normalized it and have no intention to harden. Hit it a few times with a smaller hammer and it hasn't break. Conclusion: I have tried to forge this alloy, did not success with it, but can be in peace for the rest of my life because 1.2080 is checked. Yeah, and now I have a big piece left to use it for spark testing. Bests: Gergely -

I'm no bowie fan, James, but it looks like you can manipulate me that way Real good job! Bests: Gergely

-

Forging D3 / 1.2080 tool steel

Gergely replied to Gergely's topic in Blacksmithing, General Discussion

Okay, thank you! Heat treating it looks pretty tricky, too - I assume you did it in proffesional owen? -

Forging D3 / 1.2080 tool steel

Gergely replied to Gergely's topic in Blacksmithing, General Discussion

Thanks guys! I use a power hammer - so hopefully no big issues with hard hammering. Yeah, that's what I found, too. Quite sensitive to heat. Any personal experience working with this stuff? Bests: Gergely -

Has anyone experience forging 1.2080 / AISI: D3 / England: BD3 / EU: x210Cr12 (Bohler K100) cold work tool steel? I have read the minimal info I could find, but really like to hear if someone has done actual work wtih this stuff. I only want to have some fun with it. Bought a 400 mm / 16" long 25,5 mm / 1" dia piece to see what can I do with it. Also it's the highest C content steel you can buy around here, so wanted a bit for the spark test archives, too. I've read it has some difiiculties when heat treating and generally pretty oversensitive for not-suitable heating. If you can add any info, please do so. Any comments are welcome! Bests: Gergely