-

Posts

2,307 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Jim Coke

-

-

Greetings,

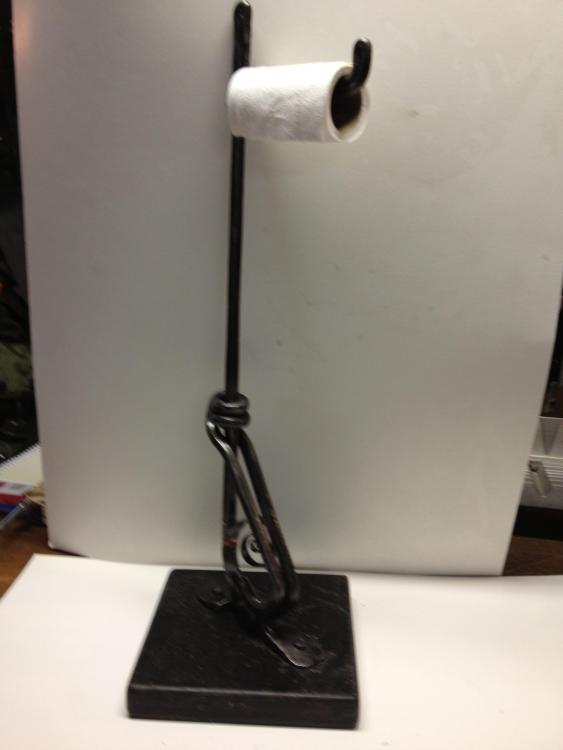

Just finished the bud vase. I enjoy taking a single piece of metal and forging it and see what evolves. A challenge indeed. With no interruptions or welds.

Bud vase 1/4 x 3/4x12in

Candle holder 1/2 x1/2 x 24In

I did add one piece of copper for the drip pan.

Forge on and make beautiful things

Jim

-

Greetings Follife,

Just a suggestion . Next time use more curl on your coat hooks. A bit to sharp for a heavy hanging coat . Just this old boys 2c .

Forge on and make beautiful things

Jim

-

Prayers sent and I will ring the anvil in the AM

forge on

-

Greetings Ted,

I made mine a few years ago. My design has a base with a hoop and is secured by a wedge under the hardy hole. The advantage of my design is the adjustable height. I use blocks under the screw to secure the stock. If we keep going with our designs I’m sure one of us will build a better mousetrap. LOL

Forge on and make beautiful things

Jim

-

-

I was at an auction a few years ago looking to buy an old gas engine. After waiting 4hours in the rain wet and cold the engine was put up for bid . The last item . Up drove a fellow in a shining Cadillac to put in his low bid. I was not going to let that happen . I bid him up until I could see him turning colors . I backed out but he paid much more than I was willing to pay. Ya think he knew the auctioneer. Yea right.. I have also watched people shuffle items of great value into the box lot bin.. At another auction the item of interest for me was a full size windmill. Of course it was again the last item . It was on the ground and and I think they were hoping for a no bid. Yep I bought it ultra cheap.. The auctioneer laughed at me and said I would never be able to get it home. A few clamps , a trailer axel and a clamp on trailer hitch and I drove it home. Auctions are fun and frustrating for sure.

Forge on and make beautiful things

Jim

-

Greetings All,

For the life of me I don’t understand the value of an anvil based on price per pound. We buy meat, produce, grass seed by the pound . Diamonds we buy by quality CCC. I have been involved in blacksmithing for some 45 years and have bought and sold many anvils. I still have more than I have finger and toes. All super quality. Some by today’s prices over 2500 and a few 300 ish. Oddly enough my every day anvil was a gift from a family member ( priceless) . The truth . A true smith can do quite well on a section of railroad track. Probably his or her first project would be a few tools to add to the track. Just this ol boys 2c . There are still many anvils out there be wise and look for quality not weight or price per pound.

Forge on and make beautiful things

Jim

-

Greetings MCB,

Make a stand on base for your vise . You will still be able to move it on the wheels . I have a few mounted this way and been using them for years. Much more stable using your weight otherwise it will tip over when using your vise for twisting longer stock.

Forge on and make beautiful things

Jim

-

Greetings Pr3ssure,

Be sure to assemble the jaws in the correct slot .. Note the numbers.

Forge on and make beautiful things

Jim

-

Greetings 556,

You can just rent a car hauling tandem from U haul for cheap and save yourself A two ton aggravation. Much easier to load and unload. Just this ol boys 2c.

Forge on and make beautiful things

Jim

-

Greetings,

I made mine from a scrap casting and I added a pulley from my line shaft shop . It’s been there for years with no problem. Use your imagination and come up with something cool. I would form a large circle than tie the ends in the center in a square knot. Welding all the links of course.

Forge on and make beautiful things

Jim

-

Greetings 58er.

Best make that 50x50 .. Ya gunna need more power. Just a step up from the power hammer that you bought from my friend Dave.

Forge get on and make big things

Jim

-

Hofi

in Prayer List

Great news. Ya just can’t keep a GREAT man down.

Forge on and make beautiful things

Jim

-

Greetings Ironbelly,

Straps and hot iron don’t mix. Won’t last long. There are several ways to mount your anvil posted on this sight. READ READ READ

Forge on and make beautiful things

Jim

Beat me to it Irondragon

-

Greetings Rojo and Dave,

i think you got the idea for old socket adjustable bending forks from me long ago. I also make forks that extend over the side of the anvil that are secured by a wedge in the hardy hole. All work great for different applications. Have fun

Forge on and make beautiful things

Jim

-

-

Greetings Farmall ,

Back in the day it was common to go to the basement to start the old coil water heater . No pilot light at that time . That striker is long to reach into the burner. Just my thought.

Forge on and make beautiful things

Jim

-

Greetings P3ressure,

Pretty color however there are very few spots on my anvils that I don’t use to form metal . A nice new paint job wouldn’t last long and it would look like a spotted leopard. Pink highlights would be cool in the lettering and weights.

Forge on and make beautiful things

Jim

-

-

Greetings Welding Rod,

It looks like an Acme that was sold through the Sears stores . It is a 2 speed . If you move the crank hub to the other gear you can go to slow speed : I have several and use them all the time. They are great for kids to learn and of course they are cordless. It looks like you have an adjustable table. Can’t tell by the Picts. Have fun

Forge on and make beautiful things

Jim

-

Hofi

in Prayer List

Anvil rung with one of his wonderful hammers

-

Greetings Mihai,

Another solution is to cut thick wall pipe for depth control in place of the collar lock . Split the pipe in half than a simple hose clamp will hold it together. Doing it this way the kiss block will not get in the way I the work.

Forge on and make beautiful things

jim

-

Years of dedication , research and a bunch of cash so others can learn and appreciate the Fisher anvil brand. It’s no wonder magnetic north is changing. Probably pointing towards NJ

-

Greetings Ted;

I moved mine 200 miles. I rented a lowering hydraulic trailer that worked quite well . The trailer drops down to about 8 in. They move around the shop with a hydraulic floor jack pretty easy.

Forge on and make beautiful things

Jim

What did you do in the shop today?

in Blacksmithing, General Discussion

Posted

George,

You are oh so correct. I took some pieces to a demo last week and I think this one got a little squished. I’ll fix it shortly. I’ve made others more complicated. They all seem to end up differently.

Forge on and make beautiful things

Jim