-

Posts

2,307 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Jim Coke

-

-

Greetings Swiss,

I just posted a picture of one I restored .. “Champion 1898 blower”. The picture shows the belt arrangement which would be the same as yours. Restorations are a challenge and many parts have to be manufactured.. Good luck and have fun

Forge on and make beautiful things

Jim

-

-

Greetings Dick,

Take your round stock place it on your cut off tool cold ... tap tap tap ( small mark ) than turn it over visually center the mark and tap tap tap ... normally this is more than accurate for punching .. ( good ol boys way ) .. Good luck

Forge on and make beautiful things

Jim

-

Early Fisher... Josh will chime in..

-

-

Greetings Finn.

Just start with a simple hook.. If you use a chunk of round stock 1/4 .. 5/16 .. 3/8 ,, you won’t need tongs.. If you have a cut off hardy tool it’s good practice.. Keep trying keep trying. No such thing as failure... After 40 plus years at smithing I still have my first forge weld..

Forge on and make beautiful things

Jim

-

Greetings Dick,

Do you want bulged sides? What size punch? To save what you have drill a1/4 through hole on center .. grind a slight point on your punch than bright yellow heat .. Cool the bulged side slightly ( I use a super wet rag) alternate with a flat faced drift. You are. Trying to compress a lot of metal at a time ... For iron that thick I slit and drift . I all depends on the desired hole size.. For round stock I start with a forged flat than support on a swage block. I hope this helps.. I’m sure others will chime in ( if you ask 10 smiths for help you will get 60 different soloutions to fix the problem. ) I hope this helps.

Forge on and make beautiful things

Jim

-

Greetings Al,

A simple way is make your pipe stick up through the forge about 3inches or so ... sand on the bottom than a few fire bricks to top it off. Add a grate over the tuyere and your good to go. Fire bricks are available at most fireplace or wood stove shops..

Forge on and make beautiful things

Jim

-

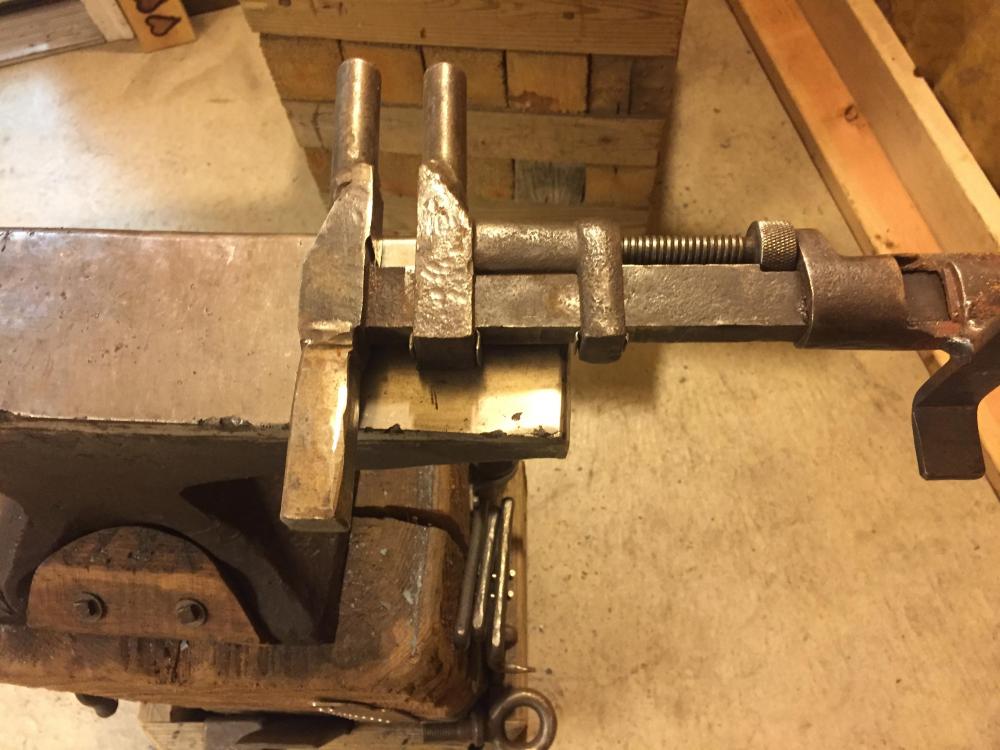

Greetings Dionne,

Great vise .. Just use a magnet on the screw box to determine if is iron ..

Forge on and make beautiful things

Jim

-

Greetings Twisted,

All the smiths that see me use it named it ,,. Now that’s slicker than Sh- -

-

Greetings JLP,

Yep it’s armstrong... You only see just a few things that I do with it . Notice the rails and staggered pins . Great for straightening. Many other fixtures fit in the hardy with a wedge.. I’m surprised nobody ask what STS means. Bigger stuff I do on the acorn table with pins and forms. And yes I also have a Hossfield.

Forge on and make beautiful things

Jim

-

-

Greetings Joel,

An antique cold metal do all shopsmith ? I too wish there was such a thing.. When you stopped by for a visit you walked right by mine that I made.. Next time I will give you a demo.. By the way the Whitney angle cutter / bender has a bender device just like the video.

Forge on and make beautiful things

Jim

Just a few things I can do with mine.

-

Greetings Setlab,

For sure get it.. The base would make a great portable work space.. The pulleys make super bending forms and the shafting great round stock for other projects. The drill press as a drill press not so much.. The picture is my invention that is a multi functional fixture that allows multitudes of various bends .

Forge on and make beautiful things

Jim

-

Greetings All,

I do not think the taper would fit a Pexto plate... My guess is some kind of a locater or guide for a machine . What function would the machined flat be? Just this ol boys 2c.

Forge on and make beautiful things

Jim

-

Greetings Dave,

Gosh I never made a mistake like that... Yea right... What I do is make a removable weight on the lever which keeps the clinker breaker in position. Keeps the air flow consistent. Have fun.

Forge get on and make beautiful things

Jim

-

Greetings Aus,

Easy to make. I start with 1/2 round bar. The split allows for a wider stance and stability. Have fun.

Forge on and make beautiful things

Jim

-

Greetings Traci,

Look up MABA .. Michigan Artist Blacksmith Assoc. Our Michigan group has many members in the UP and they would be more than willing to help you along. I’m in the lower near Cadillac and the forge is always open.

Forge on and make beautiful things

Jim

-

-

Greetings Toolgal,

My guess would be a hole centering devise . If you had 2 boards one with a large hole and the adjoining board with the smaller hole you could index the parts so other holes could be drilled and the parts properly indexed. Just this ol boys 2c

Forge on and make beautiful things

Jim

-

Greetings OC,

It was your lucky day, A great anvil and worth more than twice what you paid. Now get to work and make something to post on IFI.

Forge on and make beautiful things

Jim

-

Greetings Lyuv,

As Glenn and Basher pointed out local heat control . Just heat the bar than cool the parts that you don’t want to twist by dribbling water on it and it will work just fine . Done it thousands of times.

Forge on and make beautiful things

Jim

-

Greetings All,

Yep John is right ( again) .. I was sure he would chime in with the correct answer. Got one somewhere in my vast piles of stuff.

Forge on and make beautiful things

Jim

-

Greetings Jamal’s,

Had one and sold it for to Mr Postman. For hi collection He said that Enderes did not make anvils larger than 12 pounds. Mine was probably a prototype. As I remember the face was soft and dented easily. Best check rebound and hardness.

Forge on and make beautiful things

Jim

Restore a Canedy Otto belt driven handle pumped blower

in Bellows, Blowers

Posted

Greetings Bob,

Until you are familiar with this site I will post the pictures . Lots of questions . The pictures will show the belt arrangement and yes it is a great blower .. Lots of air.. When you find my previous post others have chimed in with comments. Start your restoration and post questions as you go..

Forge on and make beautiful things

Jim