onetreeforge

Members-

Posts

274 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by onetreeforge

-

Thats not good, yes the US has come off worse than any other place

-

Everything has come to a standstill, the country has been covid free for a year but we are having an out brake and it a lock down time, i don't know for how long, i had a truck load of gravel and new springs for my power hammer which were coming but i don't know when i will see them, everything's shut for a week which could turn into 6 weeks

-

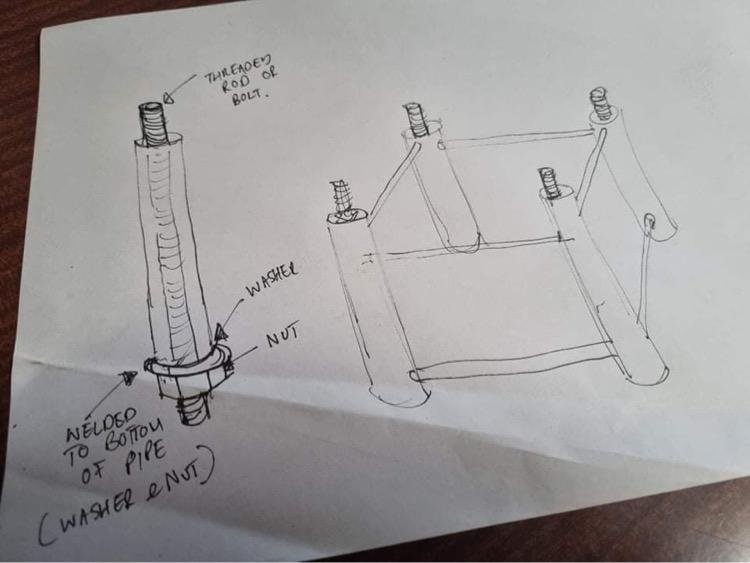

They are about 35mm bolts or threaded rod they won’t be snapping in a hurry, I could use socket nuts for extra thread engagement, In would weld on a lot more steel to the frame, I can’t find anything suitable locally for concrete anchors

-

Earthworks are finished, that spot is a lot bigger than it looks in real life, I got them done for free for repairing the digger trailer for the guy, I need to get the hammer and it’s anvil moved into the spot, and I am doing a deal on repairing a compactor for another guy who has a mechine to move it. someone drew me this plan for a way to hold the hammer to its foundation with bolts rather than have to lift it over studs. Getting power to the shop is going to be a pain, I wired up the old shop and ran 16mm2 cables underground from the house but this is too far from the house to do it, I will probably run an over head line to the power. We don’t have 110 volts, everything is 240v witch is nice.

-

Do they still use it for fillings? I wonder what happens to the dentist after using it for years?

-

Liquid Mercury is quite safe, you could xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx. Someone I know xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx. mercury vapour is the bad one

-

-

Atlas power hammer

onetreeforge replied to onetreeforge's topic in Power Hammers, Treadle Hammers, Olivers

I cut 19mm from each link and ARC welded them back together, if that works I will make nice new ones -

I had an engine drink a lot of Mercury out of a vacuum gauge and spray it out the exhaust when I was 19, I am 37 now, apparently I have a learning disability since school, I cannot hold down a job but I have been smithing since I was 14 making all sorts of things but mostly sculpture witch has taken me as far as Korea and Japan, it was all done in that small shop in the photo. I think in the last 15 years my health has gone down hill but it has been really bad since I was 10, anyway we got some digging done with my friends digger

-

I love fossil hunting, some lumps of coal I dosnt want to burn because of the nice ferns and stuff in them, most of my art is plant forms, I don’t think I have any Be/Cu, I may have a spring made from it somewhere.

-

I had to not wash my hair for a week, then the hair samples are sent to Germany, it’s very expensive and not covered by our public health system so I have to foot the bill. I had blood tests done and they don’t show anything and they are not reliable, I even had a copper and lead test witch were both normal, the specialist was wondering did I eat a lot of seafood but I don’t because I can’t stand the stuff.

-

99% of the work I do is bronze casting and forging copper, I cast all my copper off it scraps into ingots and pull them out under the hammer

-

I have never broken a fluorescent tube on the property, when I get the old fittings I remove the capacitors and chuck them away, most of my work is with copper and i do I do a huge amount of arc welding is where I am think it comes from. at my old work once I had a Mercury accident where I created a vapour cloud but that was 15 years ago

-

Atlas power hammer

onetreeforge replied to onetreeforge's topic in Power Hammers, Treadle Hammers, Olivers

-

I forgot to mention I collect vintage fluorescent lights lol, I have enough tubes to last my life time. i think the digger is coming tomorrow to dig a spot for the new shop

-

Yes our drinking water is rain water, that is being tested, I am right out in the bush, I have suffered health problems for as long as I can remember and possibly my body cannot detox itself like normal people, but yes I do eat a lot of rice, my arsenic was right off the scale of the test, I am worried as my main work involves forging copper, but people sed I should be more concerned about the lead but that was normal in the test

-

Atlas power hammer

onetreeforge replied to onetreeforge's topic in Power Hammers, Treadle Hammers, Olivers

The toggle links would collide with the tup when it’s at the top of its stroke as they were too long or those curved top arms need bending where the spring sits on them as it was hard up agents the connecting rod the springs did nothing. Since i I am going to make new toggles I cut the old ones down 20mm and welded them just to see how things sit, now the springs work and the tup won’t smash into the toggles and the force will go into the springs. may have to go back to the original length toggle link and bend the top, getting new springs made as the old ones are mis matched, hammer would have been down on power a lot how it was set up. -

I have had had bad heath for many years, it has gotten worse since I finished school, I got a hair test done the other day and my arsenic leaves were super high and off the chart, Mercury was also high, I always wear a double filter 3M mask and I don’t work with tantalised wood and I haven’t had my coal forge going for years, I do not understand where it is coming from? Would arc welding rods cause it?

-

If you have electronic ballasts in the fluorescent lights they are fine in the cold. I hate LED with a passion

-

I had a clear bit of corogated stuff in the roof once and got rid of it, made it 1000 degrees and leaked, LEDs are the most horrible light source ever, they brake down and don’t last, plastic junk. There is a fluorescent street light on my other shed and it has been outside since 1958 and had new tubes 15 years ago

-

Tree has some kind of sickness where the sap can’t flow and will die, when my shop is gone it will probably fall over

-

Probably to no tree forge because the big Kauri tree falls on my shop every storm and I have to pull it straight with the tractor and my shop wont be there to stop it next time getting to the point where I cant pull it back up.

-

Its almost time for my old shop to be demolished for a few reasons and its upsetting people, I have been using it since 1998 and almost full time since 2007, new shop will be 100M on the other side of the hill overlooking the Pacific ocean and be bigger with a higher roof. I have no idea on the layout but my anvil stand and vice stand will be cemented into the floor and power hammer needs a 4 ft footing, will have fluorescent lights more power points, better bench, coal forge will have flue going through the wall and not the roof as this caused a lot of problems with water leaks in the current shop. I wont have windows as I smashed most of them my mistake. I think the coal forge could go in one of the corners and power hammer could go along one of the long walls and I would like to have my big leg vice not so hard up to the wall, I have to have it underway in a couple of weeks.

-

Atlas power hammer

onetreeforge replied to onetreeforge's topic in Power Hammers, Treadle Hammers, Olivers

I think the crank pin for the connecting rod has had it, it’s hard steel on hard steel, the grease nipple was missing so water got in, how stupid a couple shots of grease before dumping the hammer outside and it would be as good as ever -

Atlas power hammer

onetreeforge replied to onetreeforge's topic in Power Hammers, Treadle Hammers, Olivers

Don’t worry I make videos for my YouTube all the time, I have a very xxxxxx internet connection and can’t use my phone data, i have a Vernier and a micromotor, I trained as a mechanic for vintage cars and motorcycles, I have pored Babbitt bearings, theses are definitely cast iron, I have one a scrape on the outside edge. No real rust putting apart from the back one witch has a mark from where the bearing shim was rusting next to it