ede

Members-

Posts

254 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by ede

-

It’s smokey and stinks. I ended up pulling it from the fire right away. It was given to me and I thought it was anthracite. The smaller shinier piece (second photo) is one I pulled from the fire.

-

Steve, are you still around? I’d like to see pictures you took of this Chambersburg 200 being operated by Clifton, Steve, and Kurt.

-

Type of steel for geologist tools (hammer and chisel)

ede replied to Chrigneous's topic in Hand Hammers

Here’s one I forged with a striker. The metal is sucker rod. It was given to another friend who has done lots of gem prospecting and he is happy with it. -

I have to measure but I estimate about 12-14" That's a good idea. I have insurance already but they never bothered to look inside. This building was originally a blacksmith shop in the 1830's. Maybe if they are double walled insulated or with the use of coke it is cooler? I did the blacksmith tap on the pipe at about 6' above the shop floor and it was too hot to the touch. I think this may be due to the coal flaming up more with the volatiles so maybe I should try this with coke since I just installed an electric blower.

-

No, Santa did not get stuck down my chimney. I've taken over a blacksmith shop where there are 5 coal forges. The exhaust system on four of the forges that were installed by the previous smith--may his soul rest in peace--does not appear to be installed correctly. So I'm looking for ideas on what would be the best method to correct the situation as I'm not a fireplace/chimney or HVAC expert. The main forge has a brick chimney and short of some modifications that need to be done to the hearth, I’m not concerned about that one, it draws well. It’s the other four coal forges that are connected together and exhaust into an opening at the center of the building where the exhaust fan is. This vents right below the dormer. I haven’t been up on the roof or ladder to inspect yet. However what I see looks like single walled tubing that is too close to the timbers rafters and joists. Somehow I don’t think it’s a good idea to vent through the dormer. Could these be ported into the brick chimney stack?

-

The ball bearing can be a minimum of 62 HRC since they are commonly 52100 alloy. I believe they are simply harder than most anvils. I have a refflinghaus, a Peddinghaus, and a recently purchased Vaughn. Tried it on my Vaughn with a 1” ball bearing for 2 bounces and noticed some small depressions. It’s a nice parlor trick and I know lots of people use it to determine rebound, by as for myself, never again.

- 49 replies

-

- hard

- peddinghaus

-

(and 1 more)

Tagged with:

-

Thanks for that Glen, will have to try it.

-

I want to build something to screen the dust from my coal and coke, think of a large perforated rotisserie barrel. I’m currently using a 5 gallon bucket with 1/2” holes in the bottom to screen the dust. However, I was told rather recently that the dust in coal helps it to coke up. Can you share a link to your “Super Sucker” JHCC?

-

Was watching a video of Torbjörn forging and noticed he was wearing a respirator throughout the entire video. Is he concerned about particulate matter from his coal forge?

-

-

A swage with a fireplace shovel depression would be neat. After you sell a ton of these, you can repay me with one gratis.

-

Restore a Canedy Otto belt driven handle pumped blower

ede replied to SwissSmith's topic in Bellows, Blowers

I have some pictures to share with you Swiss Smith. The one in the photo is a Model B Western Chief Steel Frame Blower, which has a 16 1/2" fan that produces lots of air. The Canedy Otto are known as quiet blowers as they used bushings compared to Champion that used ball bearings. I need to make a new belt for this one as I have on a temporary belt currently. What model number does yours have? The B model has an oval outlet whereas the E appears to have a round outlet--which looks like yours and has a 14 1/2" fan. Interesting theory about this being a transition piece of technology. I would like to hear more discussion or see some old blacksmith journal articles relating to this technology. A37C34C7-6C55-4A97-9993-F9998E0ED86A.MOV -

I found the air hose he appears to be using on the Home Depot sight. It does not say anything about it being approved for propane either. Product Overview The light weight of this polyurethane hose makes it ideal for applications where dragging a heavy hose is an issue like roofing. The smooth, non-marring finish also makes it ideal for indoor trim work where scratching surfaces could create damage. Poly hose has very good cold weather flexibility. Bend restrictors reduce kinking and increase the life of the hose. End fittings are field repairable, so with a knife and two wrenches a quick repair can be made to the hose if damaged. 300 psi Work Pressure. 100 ft. long with 1/4 in. NPT end fittings. 4 Year Warranty. 1/4 in. male NPT field-repairable fittings 300 psi working pressure Smooth finish does not mar surfaces Light weight for less user fatigue Very good cold weather flexibility Resists kinking under pressure Ideal for roofing, flooring, and indoor jobs

-

I don't know of any ceramic fiber blanket that doesn't need to be sealed. Ceramic Wool Insulation, Safety Alert ---> click here

-

-

Nice score. I suggest getting some anchor seal or aluminum roofing paint on the ends to keep the checking in check.

-

Is firebrick that much less friable? I'd be interested to see studies on this. Yes, I always wear a mask when cutting or machining it. I have pieces of 2600 degree rated firebrick that have broken apart quite easily and have abraded on the steel angle iron entrance of my forge. I was informed by a friend last night that he saw dust emanating from outside my forge. It was a certain light condition where the outdoor shop was mostly dark, but the single light was partly silhouetted by a large black object (his coal forge chimney) where we were able to see particles in the air.

-

I understand many people use firebrick for doors of their forge. What makes it more safe than rigidized ceramic fiber blanket though? I ask this because I see the warning for rigidized ceramic fiber blanket regularly but haven't seen much warning for the firebrick. Firebrick abrades when it is moved, becomes suspended in the air, and is made at least in part of Crystalline Silica.

-

What did you do in the shop today?

ede replied to Mark Ling's topic in Blacksmithing, General Discussion

There are crowds all around here so no one necessarily has the best vantage point all the time, but everyone at some point does. -

What did you do in the shop today?

ede replied to Mark Ling's topic in Blacksmithing, General Discussion

-

Thanks, Thomas. It was the very rough eye that had me second guessing. I actually like that rough pitted look!

-

The eye is not smooth like a drift has went through, in fact it is rough with a noticeable protrubance, almost in the shape of a whale. The surface has very rough texture caused by pitting or forging/scale. I would like to avoid taking a grinder to this using the spart test. Could this be wrought with a tool steel edge? This is a shipbuilders adze with no identifiable makers mark. Thanks Handle appears to be much newer but fits perfectly.

-

I can’t even imagine how they did that. Wish I could see the whole process somehow to better understand.

-

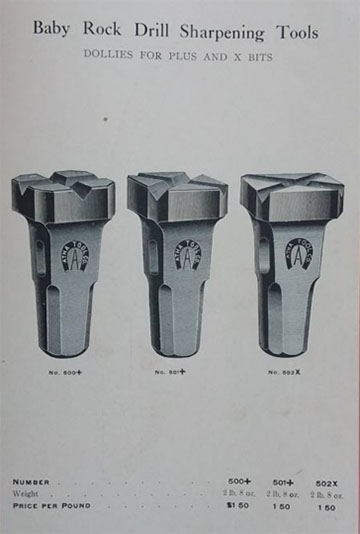

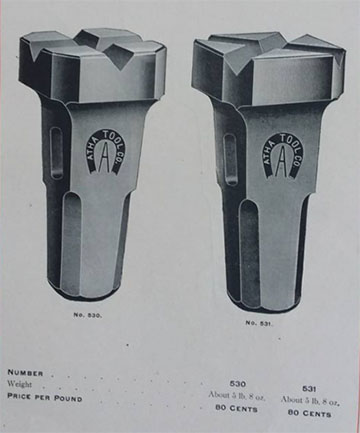

It followed me home many years ago. I believe this is a top tool used used for making quarry drills or bits.