-

Posts

32 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Archie Otteson

-

Heat treaters guide App

Archie Otteson replied to JNewman's topic in Heat Treating, general discussion

Seems like I don't qualify. Online with my desk top the page says it's not available for any of my devices. Google play store on my galaxy phone can't even find it. -

The fine tune like cleaning up welds and maybe paint. etc. Maybe I'll get around to shaping a knife soon.

-

I'm in total agreement with both Frosty and George here. I have known one particular guy all my life. We met in 1962 when our parents moved in next door in a new suburban development. We are both in the trades, Him being a machinist and myself a Heavy Truck Mechanic. We both have similar training in safety, PPE use and exposure to harmful and toxic substances. We have both have worked for some very large global corporations but never at the same company. On the surface he comes off as an intelligent wel spoke person. Over time he has become very skeptical about almost any information that may (in his opinion) be coming from a government, corporate or other perceived insidious source. Sometimes trying to convince him otherwise is a complete waste of time. He is a skeptic and there is always some underlying plot or conspiracy behind the message. It seems recently I meet more people with that attitude. The final thought here to me is, just walk away.

-

The one I have uses 1/4", 5/16" and 3/8" nuts and bolts. Then the grinder portion gets rinsed in hot water then into the dishwasher. I found out early on to store it all dry in a wood box. The time it got oiled before storage the oil "polymerized". There was one fine holed plate where the oil was so hard I degreased it with my torch. I also have a all in one like the kitchen aid. Just noi fast enough to grind season and stuff 30lbs of meat. So, I made this one in the picture.

-

What did you do in the shop today?

Archie Otteson replied to Mark Ling's topic in Blacksmithing, General Discussion

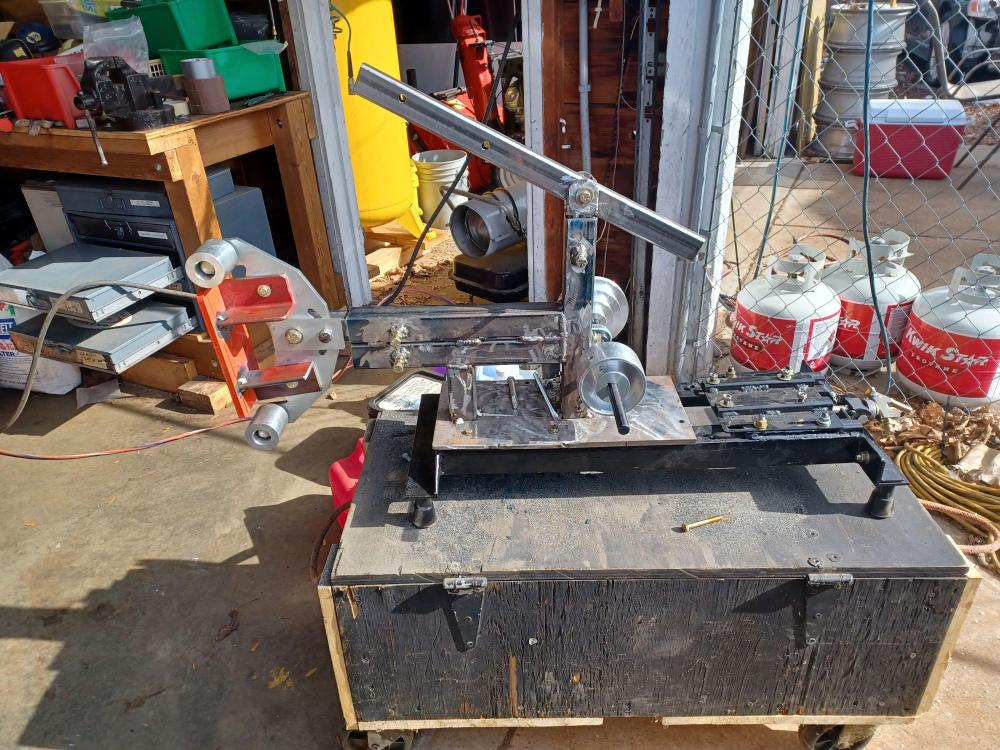

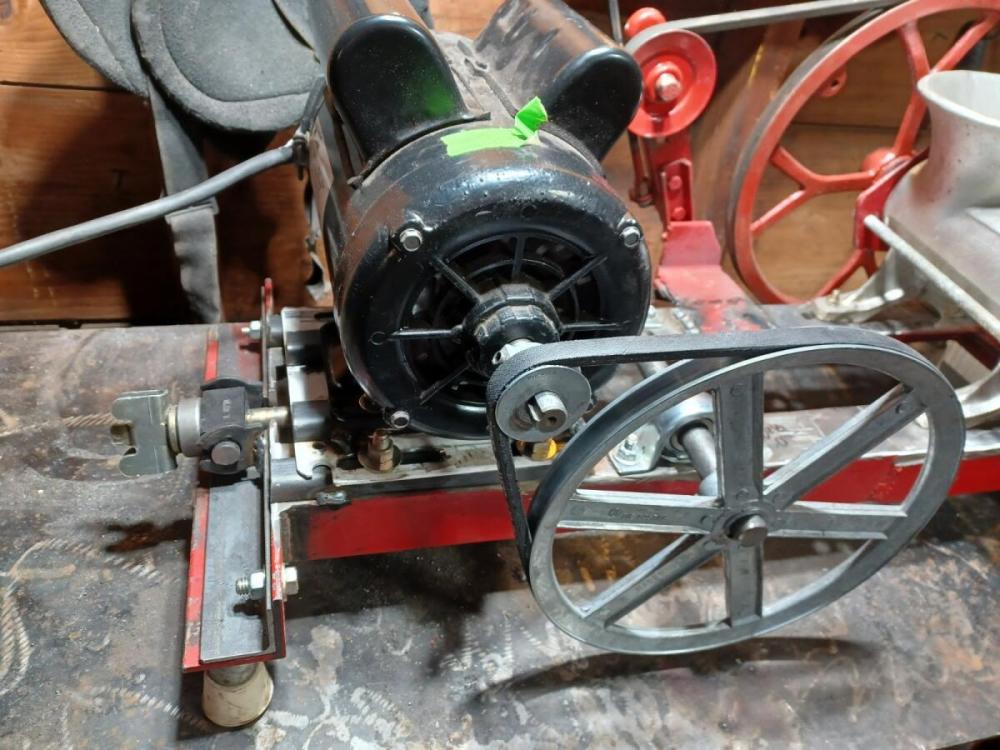

A bit more completed on the belt grinder today. I decided to use the meat grinder base for this project too. All bolt on. -

Hydraulic Cylinder rod uses

Archie Otteson replied to Archie Otteson's topic in Blacksmithing, General Discussion

I don't have anything that needs hitching except the dogs. Wifey or kids won't hold still long enough. (That's a joke) Maybe a decorative fence in front yard? Part of a "ratrod" project? Sounds like welding is an issue too. Perhaps burning the chrome off in a firepit? or grinding? I know it's a stretch, It's a beautiful shinny chunk of steel. I hate to just let it go. Well, anyways it'll get moved to the back yard for now. -

I recently came into possession of a chrome plated Hydraulic cylinder rod. It is 2" diameter and 8 feet long. All chrome is intact, and one end has the eye other end is threaded. Do you know what the steel might? Not really sure what to do with it. Looking for ideas.

-

Increasing air compressor volume

Archie Otteson replied to LeeJustice's topic in Shop Tips n' Tricks

-

Show me your blacksmith pets

Archie Otteson replied to Glenn's topic in Blacksmithing, General Discussion

-

Everything unbolts from the frame. After that cleaning is pretty straight forward. The frame gets sprayed off in the laundry tub. The ready rod is there to hold the plates on the output side. I was grinding some stiff cold meat and the threads stripped off the grinder. Instead of buying a new grinder I made those plates to hold it all together.

-

My apology for mis posting this picture. I posted this in the area because a "flash hole" is part of a flintlock.

-

I ground this knife out of a leaf spring. the heart shaped object is an original antique flashole pick.

-

This is a T/C upgrade stock from Track Of The Wolf ML supply in Elk River MN. Lock and furniture are from the donor for the Renegade stock repair. Barrel is a New green mountain .54 cal with 1:66 twist rifling. Round ball gun. This was my first very frustrated attempt at butt plate and nose cap. Nose cap and but plate top extension are Ebony wood and the rear end of the buttplate is buffalo horn.

-

Pewter nose cap on a Trapdoor

Archie Otteson replied to Archie Otteson's topic in Gunsmithing, Muskets, Flintlocks etc

-

Pewter nose cap on a Trapdoor

Archie Otteson replied to Archie Otteson's topic in Gunsmithing, Muskets, Flintlocks etc

-

Fantastic!!! I have some questions so please bear with me. First let me say I have spent the last half of my truck mechanic career putting up with newby mechanic's questions and mistakes. In my mind sharing knowledge is how we move the trade forward in a positive direction. I tip my hat to all who are willing to help out the new guys. I see the burner instructions calls for 3/4" black pipe. However, in the above post you reference using 1/2" pipe. I think that is due to the internal dimensions of the forge being used. I am using 3/4" black iron pipe only because that is what I have today. Is there a formula or rule of thumb for internal forge size and burner requirements? My stock of MIG weld tips is all .030". They can be drilled out to .035" or whatever is needed for efficient burning, so there are options here. How much will that matter? Again is there a formula or rule? I have seen in some websites guys are referencing a 50/50 mixture of Plaster of Paris and sand mixed to a clay like consistency for an insulating material. What are your thoughts on that idea? I built 2 burners this morning, not that I figure I need them today. More like having a spare in never a bad idea. How big should the forge be to need two burners? Thanks for your help.

-

First three are the meat grinder and base after latest rebuild and paint.. I'm telling you that thing will grind frozen meat without hesitation. Geared down to a brisk 85 RPM and grinder input wheel. Last two are the belt grinder in progress. I just ordered the wheel set today. I know things are backwards right now. Platen is on wrong side for the wheels. It won't end up in this exact form after the tweeking is completed. A work in progress.

-

This is how it was set up before the latest transition state. It don't look like this now with the belt grinder and gas forge projects currently in progress. Also, with gathering parts and steel for whatever might come next, it's a bit of a mess. More pics to follow as things progress.

-

Pewter nose cap on a Trapdoor

Archie Otteson replied to Archie Otteson's topic in Gunsmithing, Muskets, Flintlocks etc

The back story on the 18984 TD, It was my grandfather's when it was in original form. It hung on the wall in the mud room on his farm for as long as I can remember. My dad and Grandpa shot .410 shot shells out of her. After I began to understand firearms I discovered why they shot her like that. The barrel was corroded/eroded past the rifling and the stock was cracked from the wrist through the lock mortice. After he passed in 1990, I came into possession of her and promptly named her Clara after my grandmother. being that I can't leave anything alone it had to bring her into shooting form. I really wanted to do Grandpa and Clara justice. The stock and most the furniture was traded at a local gun show to a collector of those kinds of devices. It took me until 2005 to really decide and afford how the rebuild would go and 2010 before she was shootable. The barrel is a Green Mountain .457" octagon designed for a Sharps hand filing and chalking the files after every stroke. The stock is the result of my 3rd try at stock whittling. The first 2 were the ugliest stocks I think I've ever seen. This Walnut stock is intentionally shaped like my interpretation of a "Gemmer Hawken". Lock and action are original and the color from the original case hardening is still visible in bright sunlight. Trigger guard and sights are from a worn-out T/C renegade .54 cal. You guys already know the story of the nose cap. I made the butt plate from a piece of steel tube with some welding heating and shaping. She is rightfully chambered for .45-70 BP loads. Now that is a true labor of love. -

After I made the post I tried to edit it for content. I will be more controlled going forward

-

Thanks Frosty, That pretty much settles it for me. On another subject you just mentioned, my T burner is in the works.

-

A while back when recovering from full knee replacement surgery, I built this cane handle. After that it went replaced the shifter knob in my pick up truck.

-

Home depot lists them on their website.

-

I have too many to count of these bricks in the yard that someone used as landscape edging. I have no idea how long they've been out there. Previous owner told me they came from an old house's fireplace. They are softer than regular red brick and will mark on a concrete sidewalk. How can I test if they are actually refractory bricks? Does it really matter? Should I even try to use them to build a gas forge? Is there a concern for being exposed to the elements for so long?