NH Hunter

Members-

Posts

15 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

White Mountains of New Hampshire

-

Interests

Family & Friend, tinkering in my shop, shooting, RVing

Recent Profile Visitors

-

What did you do in the shop today?

NH Hunter replied to Mark Ling's topic in Blacksmithing, General Discussion

Got it mounted, but not sure it's where my wife wants it now. I feel some spackling is in my future... -

What did you do in the shop today?

NH Hunter replied to Mark Ling's topic in Blacksmithing, General Discussion

Looks good John. -

What did you do in the shop today?

NH Hunter replied to Mark Ling's topic in Blacksmithing, General Discussion

Got back to some metal work yesterday and this a.m. forge is figured out and running great now. The are two brackets I made yesterday to hold my wife's families spinning wheel up on our wall. There will be some runners that extend our on top to hold each set of legs, this way a shelf was not needed. Going to wait a few days to mount the runners as they were stained.and want to let the smell fade. Also working on a wall hanging bracket for an oxen yolk. Smaller one has a bend in it that I tried to straighten out, tried to do the 90 on the anvil instead of the vise. Learning in progress. -

What did you do in the shop today?

NH Hunter replied to Mark Ling's topic in Blacksmithing, General Discussion

Not in the shop but work none the less. Bucked this all up this afternoon. For reference that's a jonsered 2165 with a 20" bar. Had a great time. -

What did you do in the shop today?

NH Hunter replied to Mark Ling's topic in Blacksmithing, General Discussion

I like it so far. This is my first forge, but the directions were very good on the setup. They also use the non toxic insulation which was nice. Their customer service is excellent - I had a question on setup and was exchanging emails and was able to resolve my question quickly. I hope to figure out what the issue with the burner was later this week. Even with one burner running, it was plenty hot enough to get work done. -

What did you do in the shop today?

NH Hunter replied to Mark Ling's topic in Blacksmithing, General Discussion

Frosty, The burner closest to me was the one whistling. Inside the forge itself didn't get very orange. when I turned it off, the bottom of the forge and the sidewalls were starting to glow, but that was about it. In fairness, I only had it on about 35/45 minutes total. I'll tinker with the forge today at lunch and see if it was the wind or something else like you said. I also had to flip one of the adjustment collars and will research "tuning" a gas forge this a.m. On a side note, I'm glad I bought a 2lb hammer at the last minute on Amazon. Its just a cheap 2lb drilling hammer, but my arms didn't like the 4 and 3lb'ers to start with :). Have a great day everyone. Mike. -

What did you do in the shop today?

NH Hunter replied to Mark Ling's topic in Blacksmithing, General Discussion

Got my first forge time in today. Basic drawing out, a bend and a loop. My stock was to short but I made the best of it as I'm just learning. A basic fire poker for the fire pit out back. Have to figure out what was up with my forge tomorrow. One burner started whistling and the forge wasn't getting hot enough so I shut it down and took that burner out, back in business. I know it basic and rough but I've been waiting a long time to do this. Was worth the wait. -

Show me your anvil stands

NH Hunter replied to pkrankow's topic in Stands for Anvils, Swage Blocks, etc

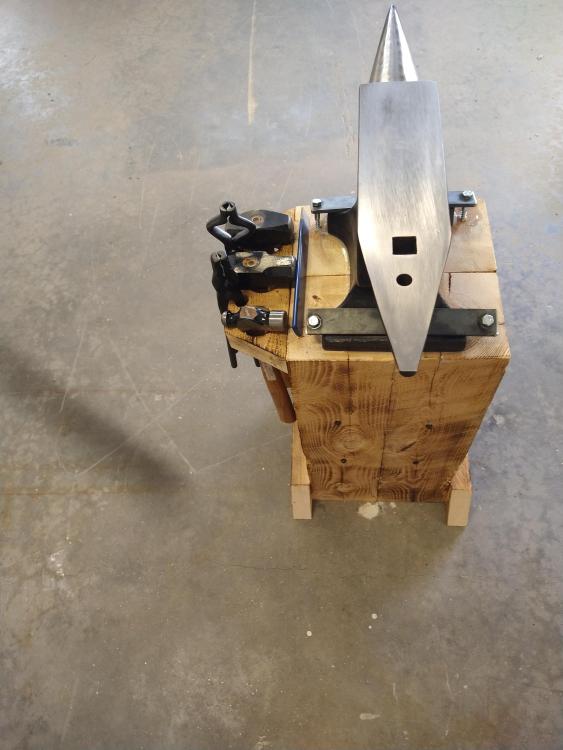

Thanks Frosty. I'm pleased with how it came out and how solid it is. When you say wider, do you mean under the horns or the sides? Not knowing exactly how I'll work, I wanted it as minimalistic as possible while being solid. I also wear a leg/foot brace due to an injury so I don't want things too cumbersome when I'm working. I also see some people post that they don't want their stands or tools under their horns so I avoided that in this iteration. I also noted that my original post says I used 10 cabin screws, that should have been 10" cabin screws and a bunch of them. With regard to the cement, yes I mean refractory stuff. I was following the instructions from the forge maker and it was only to get the last bit of moisture out prior to the second coat. I did get the second coat on later last night and will see how everything sets later today. I have to say, I'm really enjoying the tinkering part of just getting set up. Thanks everyone. -

Show me your anvil stands

NH Hunter replied to pkrankow's topic in Stands for Anvils, Swage Blocks, etc

I haven't had the chance to use it yet. With family and work stuff, I'm behind on my forge. I've rigidized and put my first coat of cement on, but its still tacky. Not too warm here lately which isn't helping. I currently have my heat gun blowing some warm air in it to help speed it along so I can get the second coat on it. Was hoping to get my first forge and anvil time in this weekend, but doubtful now. I did score a good size break rotor, 4" deep by 9" around, from my mechanic this week. will try to get that set up this weekend. Also called an Agway 25 miles away and they have blacksmith coal, so I may go up and get a couple bags. I'll update when I've been able to get some work going. Have a great Easter weekend everyone. Mike. -

Show me your anvil stands

NH Hunter replied to pkrankow's topic in Stands for Anvils, Swage Blocks, etc

Good evening. My anvil and tongs arrived today. Monday I built the stand based on my observations of this thread and not knowing exactly what I want yet. It's 12" square of hemlock with 10 cabin screws holding it all together. I hollowed out the bottom about a about 1/2" except an inch around the edges. I put caulking under the anvil and then used 1/4" bar stock to secure it down with lag bolts. I had the anvil measurements and calculated the height based on my wrist, I figure I can adjust as needed, if needed. It will get me started as soon as i get my forge set up. Thanks for all the information on this site, it is very helpful. -

Other than my kids or 2 friends I do not loan tools.

-

JHCC - PM sent

-

JHCC I'm about 40 miles South of Franconia just outside of Plymouth. I've also looked at the website the blacksmith group that has workshops. I'll kick them an email when I get home as their calendar on the website didn't show anything. It's just what I need though. Thanks.

-

Thanks for the warm welcome everyone. Just to be clear, my list isn't huge just a few things to get up and running. I'm a reader/researcher so I've read all the stickies, starter threads, etc. - not wasting money, just a few things I need. With regard to the TPAAAT - I've been doing that now for a couple years for anvil, etc. - but the area I live in has been picked over pretty well. It doesn't help that I'm not much of social person, but some of my friends are very social and have been helping as well. Again, thanks for the welcome, I've been enjoying the group for quite some time and look forward to contributing and asking questions as I go.

-

Hello, Longtime listener, first time caller... Just wanted to introduce myself. I'm Mike and I live in the White Mountains of New Hampshire although I'm technically a snowbird now, as I spend 5 months a year in Florida living in our RV. My day job is as a compliance officer for a financial services firm . I work from home, so I have flexibility. We're heading back to NH shortly and I'm really excited as I've spent the winter researching and preparing my lists of needs/wants to get started. I have a healthy home ownership garage, including metal and woodworking stuff, but have never blacksmithed. I my lists ready to go, and will be hitting the order button early next week for my arrival home. Anyway, just wanted to say hello and I look forward to the continued learning and interactions. Mike.