EpyonX

Members-

Posts

13 -

Joined

-

Last visited

Profile Information

-

Location

Cheyenne, WY

Recent Profile Visitors

-

ThomasPowers: Will do on calling the company and asking the local fire department for cleanup. Glenn: Noted for future extinguishers. Is cleanup much better with those when it comes to blacksmithing?

-

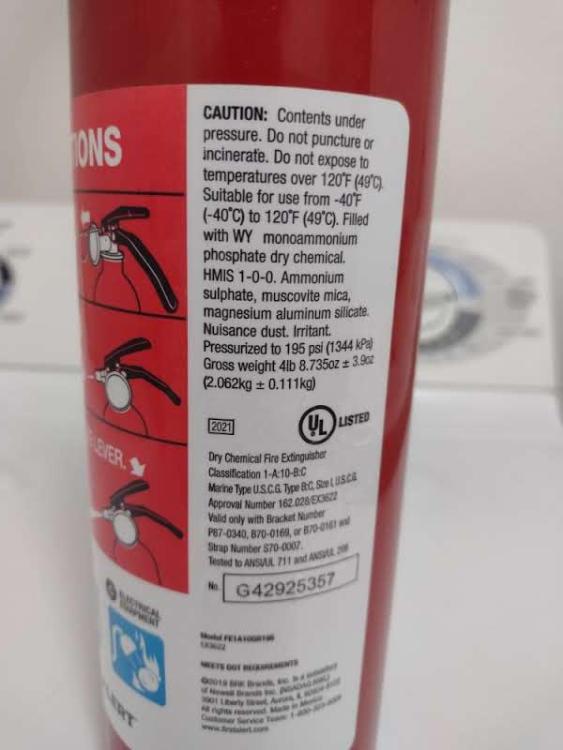

Hey all, looks like today I got to try out my fire extinguisher and got it all over the inside and outside of my forge. My question is, would it be safe to burn off the extinguisher dust once I can safely operate the forge again? Lesson learned, get a better support platform for the forge to sit on that has no wood in it at all. Here's the extinguisher label:

-

Graffiti anvil, brand new to blacksmithing...

EpyonX replied to EpyonX's topic in Anvils, Swage Blocks, and Mandrels

ThomasPowers: Here's the underside of the base if that's what you were referring to there were no markings that I noticed. There are no stampings on the heel side of the foot: -

Graffiti anvil, brand new to blacksmithing...

EpyonX replied to EpyonX's topic in Anvils, Swage Blocks, and Mandrels

Alright, looks like I just barely have letter fragments that was hidden under the paint. Got the foot stamps cleaned up too so that long number string now reads: A 108151 Here's to hoping we can finally figure out the brand... -

Graffiti anvil, brand new to blacksmithing...

EpyonX replied to EpyonX's topic in Anvils, Swage Blocks, and Mandrels

ThomasPowers: The indentation in that picture is shaped like this ">" with the open end pointing up around the 11'o clock position. Also, after looking at the base carefully I think that letter "A" before the long string of numbers might actually be an "N" if so would that change who the maker might be? -

Graffiti anvil, brand new to blacksmithing...

EpyonX replied to EpyonX's topic in Anvils, Swage Blocks, and Mandrels

Frosty: Good to keep in mind. George N. M.: Thanks for bringing to my attention that good ergonomics for a bad back is something to think about. JHCC: Thank you ThomasPowers: I finally got pictures of the base on the horn side and found some markings that are hard to read, I'm hoping once I clean it up it'll show up better. The underside is mostly solid with a small hollow under the waist. On the underside of the horn there is a hole on the waist that does not pass through, the heel side does not have a hole in the waist if that helps narrow down the manufacturer. The anvil is 100 pounds, I don't think it's been through a fire that I know of yet. A previous owner before the seller spray painted all over it for some reason. From what I could read of the markings the first picture looks like: A 1 1 8 1 5 4 Second picture looks like: 7 5 The anvil measurements are 25" from horn to heel, 3.5" on width of the face. Height is 9", foot length is 9.5", foot width is 8" -

Graffiti anvil, brand new to blacksmithing...

EpyonX replied to EpyonX's topic in Anvils, Swage Blocks, and Mandrels

George N. M.: If I remember correctly, the face of the anvil should meet right at the knuckle of a closed fist yes? -

Graffiti anvil, brand new to blacksmithing...

EpyonX replied to EpyonX's topic in Anvils, Swage Blocks, and Mandrels

Irondragon ForgeClay Works: This is the only picture I have of it facing the other way, I'll try to get a better one some time tomorrow. Last I checked that side didn't have any kind of stamping that I could see. I'm hoping once I take the paint off that letters can finally be visible. It weighs 100 pounds. If I can find a tree stump/log while scrounging around I'll probably get some solid boards for the casters and take your advice on that. I tend to have the mindset of less moving parts = less BS. George N.M.: Oh if we could get some cows and horses into the hobby we could finally outnumber OK. WY has less people than even AK last I checked, but I could be wrong. Frosty: Lucky for me I got solid ear protection, safety goggles plus face shield, and a respirator. A crappy jacket goes on when I work with the angle grinder. I'll definitely look into a leather apron though as money permits. -

Graffiti anvil, brand new to blacksmithing...

EpyonX replied to EpyonX's topic in Anvils, Swage Blocks, and Mandrels

Twistedwillow Yup, I've looked at side casters on wood for ideas since I do have access to railroad tie lumber near a scrap place. I've also seen someone put 4 casters but they had a much heavier anvil too. -

Graffiti anvil, brand new to blacksmithing...

EpyonX replied to EpyonX's topic in Anvils, Swage Blocks, and Mandrels

Twistedwillow Oh yeah, I couldn't pass up that offer especially as a beginner who couldn't afford to buy a brand new anvil quite yet. Just gotta build my stand to the correct height, put some caster wheels to be mobile in the shop and I'll be ready to learn the basics while building up the skills to get good. -

Graffiti anvil, brand new to blacksmithing...

EpyonX replied to EpyonX's topic in Anvils, Swage Blocks, and Mandrels

Twistedwillow I feel comfortable in saying below $300 for this anvil. Got it on forum rules and reading that. And it would appear I'm having difficulty finding that dang edit button so I can remove the "at" symbol. -

Graffiti anvil, brand new to blacksmithing...

EpyonX replied to EpyonX's topic in Anvils, Swage Blocks, and Mandrels

Thanks! I was debating between wire wheel, wire cup brush, or something similar to the Scotch-Brite Clean and Strip XT Pro Disc for removing paint off metal. Maybe I'm overthinking the small things, I'm also somewhat new to using angle grinders. -

Hey all, first time posting. I got lucky within the last three months of getting a Mr. Volcano Hero Forge and recently bought a used anvil from someone who wanted to get rid of it. So my questions are this: 1) What kind of grinding wheel should I use to get this paint off since I don't want to mess around with chemicals? 2) What grit wheel should I use to clean up the cut marks on the cutting step? 3) Anyone know what brand this might be? I didn't see any markings so far, but I also haven't had time to take a very close look at it yet. I wonder if there are any faded stampings under the paint. I'm thinking it might be a Trenton? Any input would be greatly appreciated.