Simian

Members-

Posts

57 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Simian

-

Traffic circles? Do you mean roundabouts? this beauty not far from me has just turned 50 years old!

-

Near impossible to make a 1/2" frosty burner in the UK?

Simian replied to Simian's topic in Gas Forges

Thanks Mikey, sadly, the external threads are needed to thread into the tee body. Also, that's tapped at M8, and I can't find a 0.6mm mig tip in M8, only M6. I'm sure I'll find a workaround, but in the meantime, I've ordered a brand new 1/2" Amal burner... Whoops! -

This is mainly a brain dump, apologies. I have all of the steel pipe fittings; 4" 1/2" pipe, 1/2" x 3/4" tee. This is all in the UK standard BSP. I have 0.6mm x M5 mig tips (I can get tips with M6 or M8 thread, but M8 aren't available in 0.6mm) I have several different 1/8" x 1/4" (BSP)pipe nipples. The bore on all of them is much too large - the mig tip falls straight through! The smallest thread I can tap them to is an M8, which makes the wall too thin and breaks them (the nipple on the right). I can only assume that you have MUCH beefier fittings stateside?

-

What's your latest blade look like? Post em and let us see.

Simian replied to HondoWalker's topic in Knife Making

That wood is beautiful. Nice work. -

Much appreciated fellas!

-

Awesome! thankyou! That's exactly what I was hoping for. One last cheeky question then; what size mig tip did you use for the 1/2" burner?

-

Hi All. Can anyone recommend a starting point for size & number of holes in a ribbon burner for a 1/2" frosty burner? Or am I on my own in a whole new frontier? is a 1/2" feasible for a ribbon burner? FWIW, this is for a pretty small forge that will be mainly used for (small) damascus billets, and will be used at sea level. But I'd like to get the interior at the most even heat possible Ta!

-

Chapeau! You really do inspire me to up my game! Is this your profession or a hobby?

-

What's your latest blade look like? Post em and let us see.

Simian replied to HondoWalker's topic in Knife Making

Full tang bushcraft blade, ball bearing canister damascus (6mm 52100 bearings & 1095 powder), curly oak handle, 8mm flared stainless tube pins. 3.5" blade, 8.0" overall. Weight; 137g. Super happy with this, the even and sharp bevels in particular. No hydraulic press, no power hammer. -

His first hit at 4 mins in had me laughing out loud

-

Awesome - Simple answers are the best! Now, being serious, you posted this in November... what have you made recently?

-

forging & holding small pieces

Simian replied to Simian's topic in Blacksmithing, General Discussion

100% wrought - it has a grain, and tears when you bend it. I had to google sucker rod - not much of that style of oil extraction going on in the UK! -

forging & holding small pieces

Simian replied to Simian's topic in Blacksmithing, General Discussion

Thanks Guys, teeny tiny tongs it is! I don't want to weld to this unnecessarily. Gazz, this is sheep fencing; Essentially old estate fencing to hold sheep in -

Hi Guys & Gals. More questions from a noob, sorry. I've just got hold of some wrought Iron - old sheep fencing - and I've tried upsetting some short sections. worked hot, it moved like butter, and no splitting1! However, these small pieces (now around 1" cube) are hard to hold with my basic tong selection. Do I need to make some tiny specific tongs, or am I trying to do things that are just too small? Any pointers welcome, thanks all.

-

Final question from me - As an aspiring bladesmith, how do you get the tang so flat? Surface grinder, hand sanding on a flat block or something else?

-

Fantastic - I've just noticed how it was done on the Natural. Truly superb work.

-

Forgive me for asking, but how are your bolsters attached? it looks as though there are no fasteners? (I'm sure there are, but I can't see them!) Such a tidy, functional and Beautiful blade, It's inspirational for me.

-

What's your latest blade look like? Post em and let us see.

Simian replied to HondoWalker's topic in Knife Making

Interesting stuff, thanks Buzzkill As it turns out a batch of 52100 bearings have arrived, so I can go ahead and prove you right!! -

What's your latest blade look like? Post em and let us see.

Simian replied to HondoWalker's topic in Knife Making

Oh, make no mistake, the blade heat treated & tempered very well It's taken a lovely sharp edge, and certainly isn't soft. I assumed all bearings were 52100, but they etched darker than the 1095 (I assumed the chrome in the 52100 would resist etch?)... The company that makes the bearings make them here in the UK (they're Bicycle bearings), and when I checked up they're an unspecified carbon steel. Thanks for the kind words, I need to practice my bevels, and 'Forge thick grind thin'... this blade is much thinner than I'd have liked (2.25mm/around 3/32in). Always learning! -

What's your latest blade look like? Post em and let us see.

Simian replied to HondoWalker's topic in Knife Making

I'm still a noob at this, so be gentle ball bearings (turned out they were plain carbon steel, not 52100) & 1095 powder = my first canister. Bubinga & brass -

Some pics of my quick change tooling; the top is the standard 1" rod and shaft collar. The bottom is some 15mm thick plate with some 40x40mm bar welded to it. the bottom tools are a piece of 50x50mm box with a 5mm wall thickness with the tooling welded to the top. That's my flat die, others have a 10mm top plate with the tooling welded to it. Hope that makes sense - sorry for the metric!

-

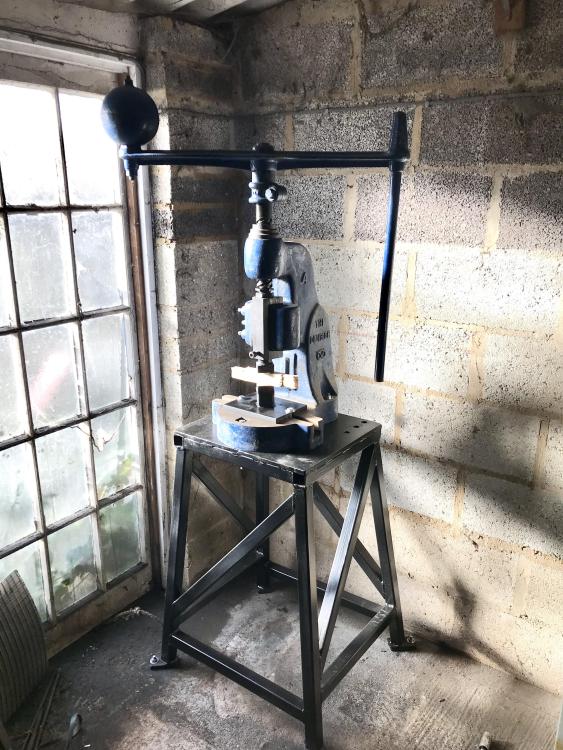

Can you weld? this is totally solid and silent. I would second that it needs to be bolted down really.

-

I have seen that - superb! Buuuut.... I had another issue - most of my work is less than an inch thick and even with some dies, I had to make up 2" for the dies to meet. I'll get some pics tomorrow, as I came up with a solution that included a quick change for the bottom tool/die. In the end I made flat dies from some D2 and some drawing dies from some old coil spring. Love this thing! Made short work of some damascus billets recently.

-

As a relative beginner myself, the best advice was from a youtube video by Alex Steele; Make 50 leaves. It teaches you basic hammer control, and different techniques to move metal just on the anvil. They're quick to make and you'll see your skill progress rapidly. You only need a hammer, anvil, forge, and a length of steel and a pair of pliers (regular everyday pliers). Tongs are a good starter project, but not if you've never forged anything ever before. Also, S hooks and scrolls. I'd argue that an equally essential tool is the Angle grinder. If you do not have one, do not pass go, do not collect $200...

-

I was asked to make a ring & jewellery holder. 6mm steel & Oak. The bowl is held to the steel with a Magnet set into the oak. I'm still new at this, so critique is welcome. I know I rushed it a little, the finish is a bit rough & ready with too many hammer marks.