-

Posts

515 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by SinDoc

-

That was put quite nicely Thomas lol. I will let him know that we/he needs to reevaluate the design.

-

Old thread but wanted to add a little to it. I work in the electrical industry at a distributor. When I was in sales I would get people who came in all the time telling me how they got an amazing deal on a compressor or some other kind of machine only to get home and realize it was 3 phase. I would typically recommend Ronk. They make several different convertors and I have never heard bad things from those whom I sold some to. Granted it was typically a farmer buying them so they didn't have to buy giant single phase motors. If you are running machinery that has a very fine tuned voltage that is has to run on, SQD (Square D / Schneider Electric) makes a sort of phase "conditioner" that can help keep everything running steady. They also have a solid line of VFD's that can be expertly tuned (if you are willing to shell out some $$ anyways). When sizing a converter, you should look at the line side load you are trying to power. If your line side has a motor on it (which I would assume nearly it always does or you probably wouldn't need the converter), look at the motors ratings. Your converter will have to be large enough to deal with the in-rush of start up. Main reason a 15 HP convertor typically wont start another 15 HP motor is because the motor on the line side pulls more power trying to start then the load side supplies it with. A short example would be say your 15 HP motor runs is rated for 15A (just made up numbers), during start up, it could take up to THIRTY amps to get that bad boy rolling. So as you can see, if you tried starting that motor with the same size motor, it wouldn't work as it would more than likely stall out the other motor trying to fire it up. Depending on the size of the motor, I would probably recommend a combination starter to handle it. Would provide a nice means of start/stop, disconnect and overload protection. I am not an electrician by any means. I am just a guy who has worked in the industry for over a decade now and have learned a lot talking to the lifers during day to day work. Most are more than willing to talk about the trade and explain things when they have time, so you just pick it up as you go. Always feel free to ask me any questions. Full disclaimer though. I will NOT tell you how to size your wire or how to wire things up. Don't want anyone trying something and causing a fire or getting themselves killed.

-

Ooooo you make light fixtures? Mind posting a couple pictures of ones you made? My primary job is lighting and I am a bit of nerd for it. You would be amazed at how expensive lighting can get. Hand made custom items can go for INSANE amounts. Not long ago I sold what is called a moon ring. It was a ring of spun aluminum that was 38" in diameter with LED up/down lights. Little bugger was 6k! Probably cost maybe $400 in parts and materials if that.

-

Would you the say his current design is flawed then and needing a total rework? I did iterate the motor issue to him and he is looking through his "pile" of motors and seeing what else he has to swap it out. If his current design is just a wash I want to let him know before he puts more work into it lol.

-

I have a pair of rubber gloves just for acidic situations. I know first hand how crappy chemical burns are. Dad whos a semi driver used to work for a company that scrapped batteries. Like industrial size forklift batteries and such. They would let him take what copper was left from wiring and such. After my first brush with that on my skin, you can bet I wore the proper PPE after that. Many a pair of jeans met their end in those containers though.

-

I know he looked at various brands before coming up with his basic design then modified it based on what I planned to use it for as well as the space in which I had to use it and mount it. I don't remember what his focus in engineering was (I just remember the broad electrical-mechanical), but when I mentioned it he said he had enough motors and misc. parts laying around he could probably build one. Would give him a project to test his various equipment and such on as he is just starting out. If memory serves, his focus was more in robotics. He interned at the Honda plants not far from my town and maintained their welding line robots. Not that that is really relevant I suppose.

-

I am not sure I would be brave enough to try cleaning chain on a wire wheel. With my clumsiness, that would be a recipe for disaster! Also Thomas, I stuck some of my hooks in vinegar a few days ago. I plan to leave them there until Saturday when the great deluge of the '21 decides to end.

-

I thought that as well and was slightly confused by it. Seems backwards to me lol.

-

I relayed the concerns you guys laid out to him and he is making a few design changes. He is going to test the motor and see how easily is stalls out then swap it if needed. I slightly jumped the gun on the completion. I guess it is only roughly 60% complete and not 90% as he still has a decent bit of stuff to do . I believe he said he took inspiration from Grizzly and their models and set rpm/fpm based off Red Labels website which states hard and hardened steel is between 1560-2940 fpm. I looked and they also list carbon steel as 4920-8820 fpm. Should he had shot for that one?

-

Had slipped my mind. I just sent it you plus a little extra for the site.

-

Billy, if I hope I don't continue to take after my mother. Last summer she got up and went walking across the living room and snapped her Achilles

-

JLP Blacksmith Teaching Center.

SinDoc replied to jlpservicesinc's topic in Building, Designing a Shop

Based on that meter, I assume you installed a 400A meter? Single or three phase? Hopefully your area allowed you to run aluminum wire to save some money. I just spent a bit reading the whole thread and found the electric part and it caught my attention . I am a lighting guy, so if you need any ideas for shop lights and such I would be more than happy to help! -

Thomas, I don't need people thinking I am anymore unhinged then I already am

-

Thanks Frosty. I just nearly spit out my drink and now everyone in the office is looking at me funny! JW515, not that I am aware of. I had the beginning signs of it in my early twenties. Had blood work and such done and confirmed it. Over the last 8ish years, it has slowly become more and more noticeable. The aching isn't unbearable (except in my right where the bones shattered) but the most annoying issue I have is the finger seizing. On the plus side, I don't need a weather app to know when its going to rain anymore!

-

I would happy if I could get cybernetic parts. Who needs a hammer? You ARE the hammer!

-

Billy, that is how my mother was getting. Her fingers/toes started twisting and she had to have titanium plates put in all of them to keep them straight and aligned. She will be on blood thinners for the rest of her life because of it, but hey, it beats having all your digits twisted into a mangled mess! Frosty, I will have to try that technique. Those pictures showed what people were trying to describe very well. Not sure if I can do the cherries, because I really don't like them . If you had told me 12 years ago I would have all these problems I would have laughed at you and I still have a long way to go! I'm only 30 dang it!

-

O fully agree with that statement. The first few weeks of only having one functional hand was horrible. I could only lightly grip something in my right with my pointer finger and thumb but even then it was rather painful.

-

I considered it Chad. While my hand was broken I had no choice but to use my left for my every day activities. Got pretty good at using it for typical task. Not sure I would trust it with a hammer though lol.

-

I don't quite have the same problem Billy, but boy are my hands unsteady anymore. Especially my right hand. Turning 3 of my metacarpals into puzzle pieces and my wrist bone into several pieces really did a number on my ability to do fine work with it. Pnut, I have not just yet. I have the beginning stages of it but it runs in the family and my mother has it really bad (she has plates in her hands/feet) and she has more or less been advising me on it lol. According to my ortho, but right hand is going to get really, really bad due to the damage from shattering it, which by the way, I would not recommend. Having 8 pins hold your hand together was, unpleasant. When I got done forging the other night, I had to actually use my left hand to open my fingers to let go of my hammer

-

That is really good info! Thanks Glenn!

-

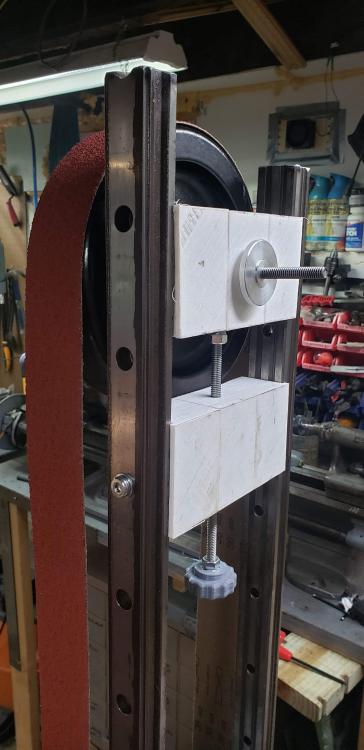

The belt tension system I believe he said isnt on yet either. I believe he said he is going to have the upper wheel utilize the rail to slide up and down to apply tension and allow quick and easy changing of the belt.

-

The belt tracking and such has yet to be put on. Its what he is working on today. This was kind of just the "shell". The platen has yet to be put on as well. He was curious if the motor would be up to par with it. Once he gets the rest done and can test it, he has other motors on hand to swap with. He may have done calcs based on a 3 phase motor which to my understanding has a little more oomph behind it. Ill have to ask.

-

Just wanted to share this. One of my good friends is a engineer who after finally finishing his some 10 years in college, decided to open a machine shop. I had off hand mentioned I wanted a grinder, but couldn't find any that I thought were affordable. He offered to make me one for next to nothing mostly to test his process and make sure it was up to snuff. He mostly worked on it during his down time and well, its nearly done! What are your guys thoughts? I think he did a dang good job. Granted, it still needs guards and such but its 90% done. Uses a 1/3 hp variable speed motor with custom variable speed control he built. 1750 rpm and ~3600 sfpm. Frame is Hiwin linear rails that were no longer usuable for CNC applications. The rollers and other misc parts are 3D printed and filled with granite epoxy.

-

I need to try and hook up with SOFA. I was looking at their site just the other day. I really hope I can manage more classes with Adlai in the future as well. As for the shock, that is just how my hand is now. Unless I have such a loose grip that I am almost not even holding the item, if I hit something I can feel the shock. That nerve is super sensitive even after the surgery. You can just tap on the base of my palm and it will send shocks up my arm.

-

I did think about trying to put a more personally fitted wooden handle on as when I took the class, Adlai's hammers were much more comfy to hold and felt...nicer? I think that is how I would describe it.