-

Posts

515 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by SinDoc

-

Anvils: A beginner buyers guide

SinDoc replied to Everything Mac's topic in Anvils, Swage Blocks, and Mandrels

Yup. When I was writing all my code for the database and doing updates, bugs would pop up that weren't even directly related to what I was updating! Almost makes you go cross eyed. 99 little bugs in the code, 99 little bugs. Take one down and patch it around. 107 little bugs in the code! -

Anvils: A beginner buyers guide

SinDoc replied to Everything Mac's topic in Anvils, Swage Blocks, and Mandrels

While I have built a database from the ground up for my work place, I am not a coder but fully understand the pains caused by forced updates. Nothing like trying to find the newly broken reference in your 20+ pages of code. -

What did you do in the shop today?

SinDoc replied to Mark Ling's topic in Blacksmithing, General Discussion

I am no professional welder by any means (hands are a tad too shaky), but that is a much cleaner looking weld then I have done in a long time, even more so with a stick (I primarily MIG weld). -

What did you do in the shop today?

SinDoc replied to Mark Ling's topic in Blacksmithing, General Discussion

Quite opposite lol. I think the closest I have ever been to you is the yearly trip to Cedar Point. I was up in the Poland/Youngstown area a couple years back for a friends wedding but that is it. Don't think I have even been in the greater Cleveland area. Maybe if they go ahead with that Amtrak rail I might have a reason to go up there! -

What did you do in the shop today?

SinDoc replied to Mark Ling's topic in Blacksmithing, General Discussion

I have never used an oxy-propane torch. Did not even know they were a thing until relatively recently. So I am the opposite of JHCC lol. -

What did you do in the shop today?

SinDoc replied to Mark Ling's topic in Blacksmithing, General Discussion

When my dad taught me how to use it, I was helping him build a floating dock and we were cutting a ton of angle iron to proper lengths. He built a makeshift workstation outside the garage on the concrete pad in front of it and it had a small tub of water underneath it to catch all the splatter so I was less likely to burn my teenage self. Geeze, that project was where I learned to use all sorts of tools. Grinders, torch, welder, impact etc. -

What did you do in the shop today?

SinDoc replied to Mark Ling's topic in Blacksmithing, General Discussion

You make a fair point Glenn. I couldn't say the last time he actually had them filled as he does not use them very often. Last I remember was a good 15+ years ago. I do know he bought new hoses, gauges and torch just a few years ago but the bottles are the same they have always been since I first remember noticing it sitting in the garage all chained up to a dolly. -

What did you do in the shop today?

SinDoc replied to Mark Ling's topic in Blacksmithing, General Discussion

I wish I had a torch. I will more than likely inherit my fathers when he decides to either start passing down his tools to clean out the garage or keels over from overworking himself. That oxy-acetylene torch has been in the family for quite some time. Granted it has had new gauges/valves since then. I recently gave him a photo that lists tool expectations that I found funny and he stuck it up on the wall above his workbench. He line of thinking follows it perfectly. If the torch comes out, he is done messing with it. Pardon if posting a meme is a no no. -

Yeah I was looking at a two stone set w/ base on Amazon. One stone was 300/1000 and the other was 3000/8000. Reviews didn't have anything terrible to say other than lack of instructions on how to actually use them. I may grab them and see how they do. They're only $40ish anyways so aren't expensive.

-

I knew I probably overlooked it. Thanks Steve!

-

I was looking around in the knife making section, but did not manage to find a post talking about sharpening. It is 100% probable that I missed or overlooked some, in which case I apologize. Does anyone have any recommendations for whetstones? I was looking around online for some, and that big online retailer everyone knows about has several different grit packs. I would assume as with everything that some are better than others, but dont know what to look for as I have never used whetstones.

-

What did you do in the shop today?

SinDoc replied to Mark Ling's topic in Blacksmithing, General Discussion

If taken off in a hurry it would double as a slashing AND bludgeoning weapon! Gotta make sure you bypass whatever damage resistance they might have. -

What did you do in the shop today?

SinDoc replied to Mark Ling's topic in Blacksmithing, General Discussion

I made a trebuchet back in my college physics class. Launched a 12lb bowling ball probably 200 or so yards. Was quite a fun project. Thomas, other than the flintlock, I don't own any guns. The wife always says if someone breaks in, they will be met with the battle axe. -

What did you do in the shop today?

SinDoc replied to Mark Ling's topic in Blacksmithing, General Discussion

I do own a flintlock (works) and roughly a dozen swords (all of which are just wall hangers). I do have one "battle" axe that could probably take an arm off though. You can bet it is very, very firmly fastened to the wall. If that thing moves, a large chunk of wall is coming with it. -

What did you do in the shop today?

SinDoc replied to Mark Ling's topic in Blacksmithing, General Discussion

You own a cannon? -

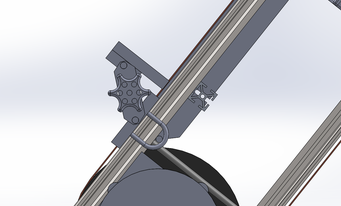

Platten. Thats the word I was forgetting. Overall, I think it is coming along. Does anyone have anymore design suggestions I could pass on to him?

-

So far he says the tensioning is working nicely. Like I said, the knob on the block in the upper part is attached to the threaded rod that connects to the upper mostly block which isn't fixed to the rails so it can slide up and down in action with the threaded rod. He said he was using it for some of his other projects and was almost not wanting to give it to me as it was working really really well lol.

-

Ill probably just leave it to my friend lol. Have him find one and pick it out and just pay him for it.

-

I did mean used. I don't want to shell out for a brand new motor . New or Used, I still have to take it/ship it down to him since he has to modify the housing and such to mount the monstrosity he built to it.

-

We have a couple bee keepers in town that the misses likes to get honey from. I am not a fan of it and have an almost aversion to bees in general. The hornet mess was the worst of it, but I had been on the wrong side of many a mess of bees in my younger years. Mowing and finding the nest of ground bees (Bumbles? Carpenters?) that don't take kindly to you mowing over their hive was never fun. Was nice satisfaction to come back with a can of gas/petrol for retribution and a nice little fire though.

-

What did you do in the shop today?

SinDoc replied to Mark Ling's topic in Blacksmithing, General Discussion

Pretty sure its just a Single Phase of many. She is still young and is very Resistant to listening. These puns have me rolling. -

More design progress! The backplate (not sure what the actually technical name is) has already been made and installed. Next is the work deck that should be attached today. Confirmed with my friend that the tensioning system works via the threaded rod and the top wheel. Using the knob allows the wheel to be moved up and down for quick tensioning and belt changes. He was able to stop grinding an item and change the belt out very quickly. He tested the tracking and it tracked beautifully. After more testing, we upgraded to a 1HP motor but it still bogs down a little bit when applying a lot of pressure to really hog off material with the 40 grit belt. Edit: I know you guys had mentioned the right HP for the motor, but 1HP was the biggest he had laying around. I am hoping to try it out and if it still is a problem, I will have to purchase a higher HP and send to him to be modified/fitted to the machine. Still trying to use what he has laying around and is free .

-

What did you do in the shop today?

SinDoc replied to Mark Ling's topic in Blacksmithing, General Discussion

I caught my daughter chewing on an electrical wire. So I grounded her. She is now conducting herself properly. -

That's a LOT of bees. I remember a few years ago I walked around the house and thought "what in the world is that buzzing sound?" only to look up and see that my girls bedroom window (2'W x 5'H) was COATED in bees. I turned around and walked the other way, quite briskly I might add. They had apparently been there a minute as they had started making combs on the window when the bee keeper arrived later that afternoon to remove them. I am not fond of bees. Let alone a large mass of them. Comes from the nasty experience of being on the wrong side of a hornet swarm in my younger years.

-

What did you do in the shop today?

SinDoc replied to Mark Ling's topic in Blacksmithing, General Discussion

There so much ambient power in here I think I just built up a static charge...