-

Posts

521 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Jobtiel1

-

-

I don't have one no, I only got the hood that the guy gave with it, I've been looking and those things cost more than the machine did, so back to hunting for one of those.

It's gonna be a bit before I'm going to use it.

~Jobtiel

-

Picked up a stick welder yesterday, runs on 220V. I got it from a guy a few streets away. I'm going to use it to weld up a guillotine tool and probably spring swages and the like.

It's not a big fancy machine, but I think its good enough for that. My brother who's a good welder will help me learn how to use it properly.

~Jobtiel

-

Very nice work Pat,

I like those bottle holders too, very elegant.

~Jobtiel1

-

Man that must've been quite the curve then. I can imagine always needing a bigger one. I went from no drill press, to buying a small one, to wanting a larger one!

~Jobtiel

-

Very cool! What do you plan to use it for?

~Jobtiel

-

Thanks! While forging I had some other ideas as well, but I'm saving those for other birthdays!

What were you thinking about? I thought about winding stock of say 6-8 mm around the bottle. You can play around a lot with this design too, especially the legs.

~Jobtiel

-

-

Yes, I wont use this for hammering of course, the plan is to use it to hold smaller items for filing, as well as general purpose stuff what you would use a normal bench vise for. I like the look of these types of vises, and over here they are pretty abundant.

~Jobtiel

-

Some packages arrived in the mail, and I (finally) got myself some large bastard files, a small vise, and an adze and calipers that were thrown in as part of the deal.

Last week I also went to a flea market, and picked up two hammers, and a drill brace. I plan on using more hand tools than power tools. And I think I have just about everything now to completely switch over. The rest I can still make.

~Jobtiel

-

Interesting insights,

Concerning the squares on the side, I think around here blocks often have them.

The price at the moment is around 700 euros, not too much for a swage block, but way too much for a student to afford right now.

Very interesting swage block nonetheless.

~Jobtiel

-

Hi all,

I recently came across this swage block on a market place site from around here. I've never seen a swage block with this design, and I thought why other blocks don't use the same design. I think it's pretty nice to not have to change the block's position to use the half round swages on the sides.

what do you think about this design, I'm curious if any of you guys have seen something like this before.

Unfortunately the price isn't right for me at the moment.

~Jobtiel

-

Indeed, the craftsmanship of the time really impressed me when you see pieces like this. The outside of this chest were pretty worn, but the lock on the inside stayed intact. Concerning the anchor I can only imagine the work that was put into a piece like that.

I also went to an old wharf where a lot of tools of the time were displayed. Couldn't take photo's unfortunately.

~Jobtiel

-

Another couple pictures of a way larger anchor sitting where the old dock used to be. In the local museum there is also this intricate lock design. I think it's dated to around 1400-1500. There were two executioner's swords there too, engraved by the original master Smith to 1387. A lot of history for such a small place!

-

Yeah, my anvil is is 240 years old, and heavily pitted when I got it about a year ago, and you can clearly see the spots I've been using the most. These spots all have flatter surfaces than the rest of the anvil. Using it cleans it up!

~Jobtiel

-

Thanks for your replies,

Concerning wrought iron, I've been on the look out in scrapyards for it, but haven't had luck in finding any, I have about 2 25 cm of 12 or 13mm square stock WI, but that's not enough for an axe. Maybe if I forge weld it together in a block, but I believe that's rather ambitious for me at the moment, since I've only done 2 successful welds, and 2 semi successful. So that's for later, I do plan on using that for an axe for myself.

Academic year starts again on Monday, so I'll be down to 1 day of forging in the week. And maybe some scrapyard and flea market runs on Saturday morning.

I want to start selling the axes once I have the whole procedure under control, so that's also why I want to start using steels I bought instead of from the scrapyard.

Concerning the alloys, for example, 15n20 has 2% nickel. So the 0.015% nickel in my steel is I think barely noticeable, and the 0.55% copper also doesn't have that large of an effect, I found some research on a steel called NUCu100, with 1.37% copper that even had improved modern weldability. So I think I'm safe with this composition. I think it has to do with metals being able to better integrate in the metal lattice compared to carbon, a non metal, and thus needing larger differences to have significant effect in the properties.

Again thanks for your replies!

~Jobtiel

-

That doesn't seem like a lot of alloying metals, so I reckon is doesn't make it that much more difficult to forge weld?

And Thomas, you're right, I don't have a lot of spending money for the hobby so cheap steel is the way to go. I also get some tool steels from a seller on a second hand site, I can't be sure the steel is the grade he says it is, but it has worked out great so far for the 1045 and 4140 he sold me.

~Jobtiel

-

I didn't know so much steel was recycled, I'll just have to wait and see how it works out then. I have send an email to the company I got it from to ask if they have more information on the presence of other metals in the steel.

~Jobtiel

-

Thomas, I was worried as soon as you mentioned it, however, it doesn't seem like the steel I bought is reprocessed, and I haven't found any information regarding the presence of other metals. I have found mentioned that the S235 steel is equivalent to US A283C steel. All sources I checked mention no presence of any other metals in the steel.

~Jobtiel

-

The steel I ordered is not exactly 1018 or 1020 I found. It's called S235. It is roughly equivalent to A-36 what I could find, in the way that it is classified by physical property and not specific composition. Thing is, in Dutch Mild steel is called construction steel, and I haven't found any dealer that sells true mild like what you mention 1018 or 1020. However, they do mention that this S235 steel is always plain carbon steel - not alloyed.

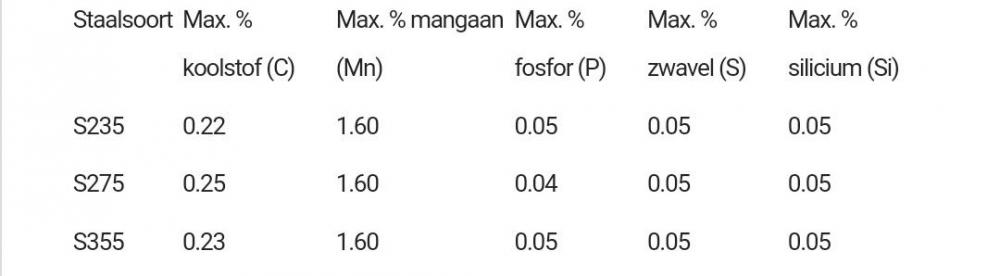

The maximum percentage of elements:

Is this bad though? Should I look for plain 1018 or 1020 instead? This is what I've been using as mild for nearly everything. Forge welding it went alright. Luckily it is not expensive to get at all. Paid 26 euros for 2 meters of 25mm by 25mm. If I forge all of them correctly that can yield me 20 small axes the way I'm currently making them.

~Jobtiel

-

Frosty, I didn't know 4140 is so difficult to forge weld, thanks for letting me know! I have ordered some mild steel and 1095 steel to use for making an axe. So I can try that the next time. Uni starts again next week so it might be a while before I can actually try it out. If that fails too I can order some 1045 round stock to use for the body.

~Jobtiel

-

Very nice work Mark and Les!

I spent the day trying to forge an axe again, since the forge weld popped open on the last one. It was too bad that after a couple tries this one didn't weld at all. I think the problem was that the metal was too cold, I tried to weld an old file to a 4140 body, and heard that welding temps were lower for that kind of steel. So in my inexperience in welding I think I didn't heat the metal enough, thinking that it was fine.

I'm trying again tomorrow!

~Jobtiel

-

Gandalfgreen, I don't know for what specifically, but I basically made a smaller version of the one I made for myself a while back. Mine has the handles angled in the same way and I use it to strip bark and fit hammer and axe handles. also for finer work like making things round for wooden corks and the like.

~Jobtiel

-

Only hardened the blade, but I did make sure the tangs were not accidentally hardened during tempering. would be a shame if they broke.

-

It followed me home

in Blacksmithing, General Discussion

Posted

Yeah I have a welding hood so my eyes are protected, and I'm not planning on welding often. I'll keep an eye out for an affordable auto darkening hood. but for now I don't think I need it to weld some small things.

~Jobtiel